C-7 Home Page

|

Telescope Engineering Company Overview

Company Seven is a TEC factory authorized retailer and showroom

Company Seven has earned a fine reputation for offering good to superb products to our international clientele. We exhibit examples of our consumer-oriented products at our showroom in Laurel, Maryland. Among items exhibited at Company Seven are historic and current telescopes and other optical systems, with a particular emphasis in first-rate telescopes for astronomy that include achromatic and apochromatic refractors made by highly-regarded names including: Astro-Physics, Carl Zeiss, Nikon, TeleVue, Unitron, Vixen, and more.

*It used to be that profit would be the reward for a job well done however, traditional values are rarely applied today. In the face of changing consumerism, and especially owing to rampant plagiarism and copyright violations of our original works by numerous E-Tailers' (including Anacortes, Astronomics, Optics4Birding, Woodland Hills Camera, B&H Photo, and others too), Company Seven long ago decided to pretty much discontinue web activities. We are posting basic information about TEC here, while reserving special knowledge for our customers who visit or contact us directly.

Right: part of Company Seven's showroom where we exhibit telescopes features our famous “Refractor Row” that includes some of the largest transportable apochromatic telescopes ever made. For sense of scale, this area of our showroom has ceiling height of 9 feet (2.75 meters).

In this perspective are (left to right): a TEC APO180FL (7.2 inch) f/7 Fluorite Triplet Apo on an Astro-Physics 900GTO mount with Particle Wave “Monolith” tripod, Astro-Physics 206mm EDF f/7.9 Apo (with "Stowaway" 90mm f5 finder, and a 90mm f/7 FL Apo photo-guide Apo telescope!) atop their 1600GTO mount and portable pier, an Astro-Physics 160mm EDF f/7.5 Apo on their 1100GTO mount with Particle Wave “Pinnacle” tripod (105,008 bytes).

Click on image to see enlarged view (372,394 bytes).

For more than twenty years Company Seven observed the development of Telescope Engineering Company telescopes. Not long after the turn of the millennium we actually were recommending people consider TEC as alternatives to some other Apos that simply were becoming unavailable new, and that were starting to command absurd premiums on the used market. By 2005 Yuri, the founder of TEC, had refined the lens designs and production so that the TEC telescopes were no longer considered by us to be 'available alternatives', but were actually being recommended by Company Seven as excellent first choices, particularly of the larger models (about 13cm) that were not being made by most other reputable companies. In June 2014 our founder spoke with Yuri about some other matters, and Company Seven's endorsement of the TEC line came up in the conversation. Yuri invited us to refer customers or even offer the line; so we actually added TEC to our Product Lines listing even though we continued to refer sales directly to TEC in Colorado.

By January 2023 we formalized our relationship and Company Seven became a TEC factory authorized retailer as TEC products began to appear in our showroom exhibit. This makes Company Seven one of few, if not the only, showroom in the world with so much Apo experience also exhibiting such a diverse range of brands and sizes of first-rate Apo telescopes.

BECAUSE WE LOVE HAVING THE BEST QUALITY OF VIEW AND VERSATILITY,

FOR THE LEAST AMOUNT OF WORK, AND LEAST WEIGHT TO CARRY OUT.

And because these look like real telescopes too!

Telescope Engineering Company (TEC) was founded by Yuri Petrunin on 1 October 1994. TEC is now regarded as one of the top-tier telescope makers,. Although TEC was originally established as a distributor and subcontractor of optics and optical materials, completing several larger professional class observatory telescopes, they are particularly well-regarded in our community for their apochromatic refracting telescopes.

Telescope Engineering Company (TEC) was founded by Yuri Petrunin on 1 October 1994. TEC is now regarded as one of the top-tier telescope makers,. Although TEC was originally established as a distributor and subcontractor of optics and optical materials, completing several larger professional class observatory telescopes, they are particularly well-regarded in our community for their apochromatic refracting telescopes.

Left: Yuri seems to always be looking up (14,787 bytes).

Yuri Petrunin was born at the dawn of the Space Age in the Ural region of the Soviet Union. Yuri demonstrated a passion for astronomy early, at a very young age the preschooler attempted to catch a shooting star in a small can. A few years later, while in primary school, he built his first telescope that was a 30mm aperture Keplerian design refracting telescope. So we at Company Seven might argue TEC's legacy of famous refractors goes back to 1966; by 2023 Yuri may be one of the longest enduring telescope makers with 57 years of experience to date.

By 1970 the amateur astronomer had learned much about the night sky. In 1978 he was experimenting with grinding and polishing his first Newtonian reflector telescope mirror. He completed that, a parabolic 200mm (8 inch) diameter mirror figured to a pretty impressive f/4; most amateur telescope makers (ATMs) tended to start learning how to do this with smaller 6 inch or smaller, and slower f/6 or f/8 mirror making kits.

Four years later he completed a 250mm f/5.6 Newtonian telescope with an Cassegrain f/20 focus. This was supported by his motorized Alt-Az mount and portable pier. This telescope incorporated some ingenious ideas, possibly even patentable. The telescope Finder for example was incorporated into the optical tube assembly with an arrangement that not only permits the Secondary Mirror send light from the telescope main optics to the focuser, but the Secondary could be shifted to divert light from the Finder to the main focuser and eyepiece too. By 1984 Yuri was building telescopes that would impress most amateurs, especially with the increasing sophistication and motorization of his equatorial tracking mounts.

Four years later he completed a 250mm f/5.6 Newtonian telescope with an Cassegrain f/20 focus. This was supported by his motorized Alt-Az mount and portable pier. This telescope incorporated some ingenious ideas, possibly even patentable. The telescope Finder for example was incorporated into the optical tube assembly with an arrangement that not only permits the Secondary Mirror send light from the telescope main optics to the focuser, but the Secondary could be shifted to divert light from the Finder to the main focuser and eyepiece too. By 1984 Yuri was building telescopes that would impress most amateurs, especially with the increasing sophistication and motorization of his equatorial tracking mounts.

Right: appearing quite professionally well made, Yuri's 250mm (10 inch) Newtonian-Cassegrain telescope as completed in 1984.

This telescope features a selectable Newtonian f/5.6 and Cassegrain f/20 focus, with the integral selectable Finder, and motorized mount (33,900 bytes).

Click on image to see enlarged view (65,061 bytes).

By 1984, and into 1985 Yuri was building telescopes that would impress most amateurs, especially with the increasing sophistication and motorization of his equatorial tracking mounts. Yuri earned his Master's Degree in Physics in the Soviet Union. Then September of 1984 also saw another, most important and fortunate milestone in life when Yuri and Anna were married; they would commence to build a family, and later, a business together.

The 1970s and 1980s in particular had seen the availability of recently developed extra-low dispersion optical glass types that would make improved, more compact, and more versatile refracting telescopes possible. In the forefront where low-disperson glass types being developed in by Nikon and Canon of Japan for their state of the art camera lenses. The Carl Zeiss Jena company of East Germany, and later the Japanese Canon company, developed techniques to synthesize optical grade Calcium Fluoride elements in high enough purity, and in sizes large enough, for telescope optical lens making. These materials combined with improvements in computer aided lens design software led to landmark breakthroughs. These generations of top rated astro telescope included the Calcium Fluorite doublet and triplet refracting lenses made by Canon Optron, Inc. of Japan and marketed by Takahashi and by Vixen. These were followed by the Carl Zeiss Jena APQ telescopes announced in 1985. Later the Astro-Physics EDF telescopes were introduced in 1989, these employing extra low dispersion fluorocrown glass, these instead of Calcium Fluorite but with similar good attributes. These developments drew attention of the astronomy community to the refractor as no longer being long, unwieldy, narrow field of view dinosaurs: they were now being portable and highly versatile instruments. The Astro-Physics brand in particular were very affordable, so valued by consumers that they tended to command premiums if one popped up on the used marked; simply put these are difficult to make well and so Astro-Physics was from the 1990s on hard pressed to meet consumer demand.

It was about this time in 1990 when the young engineer with his wife and child were visiting Brno, Czechoslovakia. While there they slipped away and escaped to the west, while in Germany they applied for political asylum. It was on 23 March of 1991 when the family arrived in Pennsylvania. They were helped to settle in by members of a local church in Scottdale, a borough in Westmoreland County, about 32 miles southeast of Pittsburgh. Accommodations were arranged, they were helped with aspects including learning english, how to drive a car and obtain a license, etc. It was here where Yuri even bought his first personal computer, an Apple McIntosh. There were government programs to assist immigrants and these had helped, but this family was motivated and sought employment and better integration into their new country.

Having his degrees opened some doors in the USA for the more than ninety job applications he submitted however, he amassed quite a collection of polite 'sorry we found somebody else' letters in reply.

In the Soviet Union he had been an amateur telescope maker (ATM) so it was good fortune when early in October 1991 he received the November issue of “Sky & Telescope” magazine. Reading that inspired him to apply for work, so he mailed letters of introduction to two of the advertisers who were manufacturing telescopes. He was drawn to an advertisement by Celestron International, and another by Jim's Mobile, Inc. (JMI). Luckily for Yuri and for our community, Celestron never responded.

JMI was founded by Jim Burr in Evergreen, Colorado to manufacture telescope accessories. Later JMIs developed the NGT series of innovative reflecting telescopes, and they even built binocular reflecting telescopes, all for the amateur astronomy market. On 7 October 1991 Yuri wrote a letter to JMI congratulating Mr. Burr on the advertised mention of having sold their 50th NGT-18 telescope, then introducing himself and asking for employment. Yuri was invited to meet, then was hired by Jim Burr. Yuri and his family, now three, moved to Colorado. He worked for JMI for about two years where he assembled telescope focusers and other components, NGT telescopes, and also did some design work. It is quite possible that Yuri may have interacted with one of Company Seven's techs while he was there, as we have been a representative for JMI for decades before the company was sold; we continue to offer what Farpoint Inc. has taken over and resumed producing.

While Yuri's english improved, his Russian fluency was an asset as JMI communicated with firms in the former Soviet bloc, including INTES of Moscow, who were then transitioning to western economic models. Yuri attended his first major amateur astronomy event in 1992, the Riverside Telescope Makers Conference (RTMC) event near near Big Bear City, California. The annual event drew particularly innovative people over Memorial Day weekend, its last gathering would be 2013.

In 1993 Yuri was attracted to relocate for an engineering position offered by a chemical corporation in Ohio. However, as he was in process of leaving Colorado the proposed hiring offer was unilaterally changed to a technician position. Yuri had already committed to the move, but was not pleased by the change. After nine months in Ohio, Yuri decided to work for himself; he and his family (now four) would build his company in Colorado.

Telescope Engineering Company (TEC) is a small business based in Lakewood, Colorado, USA. TEC has earned a world-wide good reputation in optics, and today are be best known today as a maker of fine Apochromatic (Apo) refracting telescopes. They also manufacture binocular telescopes: paired matched TEC Apos arranged in parallel working as a premium binocular telescope for terrestrial panoramic work and for astronomy.

Telescope Engineering Company (TEC) is a small business based in Lakewood, Colorado, USA. TEC has earned a world-wide good reputation in optics, and today are be best known today as a maker of fine Apochromatic (Apo) refracting telescopes. They also manufacture binocular telescopes: paired matched TEC Apos arranged in parallel working as a premium binocular telescope for terrestrial panoramic work and for astronomy.

Left: the trademark of Telescope Engineering Company (TEC), this was developed in 1994.

Materials, including some for making optics, had been developed by the Soviet Union; some of these were innovative though many mimicked the performance of materials that had been originated the west. Among these were the crystalline glass-ceramic materials that featured an ultra-low coefficient of thermal expansion (CTE), and they have other properties that made them good substrates for mirror telescope making. These are generally termed ultra-low expansion (ULE) materials, not to be confused with the Corning® ULE® titania-silicate glass, another state of the art ULE material. In the west these materials had included Cer-Vit made through 1978 by Owens Corning, the ZERODUR® made by Schott AG, the Corning® ULE®, and some glass types including Fused Silica originally developed by General Electric Corp. The Soviet Union developed a comparable ULE type of material, Sitall CO-115M, that also known as Astrositall.

Yuri exploited his Russian connections so that when TEC opened in October 1994 their initial offerings included Sitall mirror substrates Yuri could import directly from Russia. At the time Sitall was produced by the Lytkarino Optical Glass Plant (LZOS), a large optics factory founded in 1934 at Lytkarino in the the Soviet Union. The factory could provide mirror blanks, or they could deliver completed mirrors made to the customer specifications. LZOS are now part of the Shvabe OJSC Holding company, that is a subsidiary of the state-owned Rostec corporation of the Russian Federation. Up to the 1990s Sitall was generally well regarded as a good value and suitable performer. Eastern European products were then very price competitive with similar western goods.

Yuri exploited his Russian connections so that when TEC opened in October 1994 their initial offerings included Sitall mirror substrates Yuri could import directly from Russia. At the time Sitall was produced by the Lytkarino Optical Glass Plant (LZOS), a large optics factory founded in 1934 at Lytkarino in the the Soviet Union. The factory could provide mirror blanks, or they could deliver completed mirrors made to the customer specifications. LZOS are now part of the Shvabe OJSC Holding company, that is a subsidiary of the state-owned Rostec corporation of the Russian Federation. Up to the 1990s Sitall was generally well regarded as a good value and suitable performer. Eastern European products were then very price competitive with similar western goods.

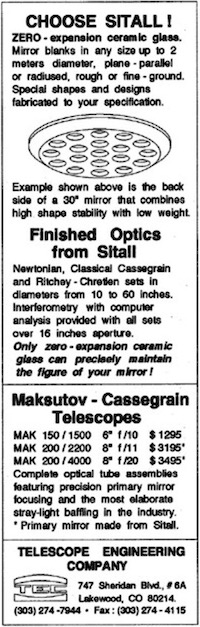

Right: a TEC advertisement for Sitall. This was a 1/6th page column, in the January 1995 issue of “Sky & Telescope” magazine (76,977 bytes).

Since the issue was mailed early in December, this ad copy would have been provided to S&T by about October 1994.

Click on image to see enlarged view (114,640 bytes).

Incidentally, decades later the formerly good reputation of Sitall had become tarnished due to mismanagement in Russia that led to variable consistency of the product, and problems with availability.

Yuri also distributed large mirrors and optical systems from Leningradskoye Optiko-Mekhanicheskoye Obyedinenie (literally the Leningrad Optical Mechanical Association, or LOMO) that was founded in 1914 at Petrogradof, formerly Leningrad in the Soviet Union, and now St. Petersburg in the Russian Federation. Yuri also sourced optics to produce a line of Maksutov-Cassegrain telescopes ranging from 6 inch to 10 inch aperture that were made in Kiev (Ukraine). TEC were successful in all of these products, and in total imported to the USA eight systems over 1 meter size. Seven 1 meter systems were installed on Mt. Wilson, California, as a multi-array interferometer project searching for exoplanets near the stars closest to Earth. A few large meter-class Cassegrain systems were made for Japanese subcontractors with their largest, a 1.4m Cassegrain system, installed at an observatory in South Africa.

Later in the 1990's Yuri decided to set up their facility for the production of their own optics and complete telescopes. TEC imported to the USA a complete line of equipment for manufacturing and testing. In 1998 TEC commenced production of optics in Golden, Colorado, USA.

As the turn of the millennium approached, Yuri began development of their first apochromatic refractor telescopes. The first one to be completed was a APO200FL, an 8 inch aperture telescope featuring a true calcium fluorite middle element (derived from the landmark Carl Zeiss APQ lens design of 1985), hence the FL suffix; this first large Apo refractor was completed in 2000.

As the turn of the millennium approached, Yuri began development of their first apochromatic refractor telescopes. The first one to be completed was a APO200FL, an 8 inch aperture telescope featuring a true calcium fluorite middle element (derived from the landmark Carl Zeiss APQ lens design of 1985), hence the FL suffix; this first large Apo refractor was completed in 2000.

By 2002 TEC established routine serial production of smaller Apo refractors, with the first production model being the APO140ED, an f/7 triplet Apo. This 140 is a 5-½ inch aperture oiled triplet, featuring extra-low dispersion FPL-53 fluorocrown glass element. While they produced Apo telescopes as small in aperture as 110mm, their 140 turned out to be a good choice for TEC's introduction to the market, as there were no premium Apos of this performance and price being routinely produced. The APO140ED and succeeding APO140FL calcium fluorite triplet apochromatic refractors have been TEC's best selling telescopes; since deliveries commenced at the end of 2002 more than 900 of these models of telescopes have been sold, with a number configured into binocular telescopes.

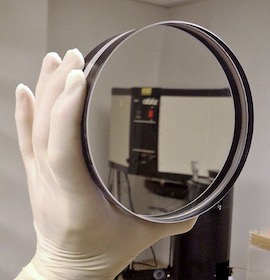

Left: this is what a great lens looks like, outside its cell, a TEC APO140FL triplet apochromat lens assembly (24,328 bytes).

Click on image to see enlarged view (71,706 bytes).

Soon after the 140's the TEC product lineup increased to include larger triplet Apo models: the APO160 (6.3 inch), the APO180 (7.1 inch) and APO200 (7.9 inch). Apochromatic refractor production continues to make up the majority of TEC's ongoing production. The APO140FL continues to be their model with the highest production quantities, regardless the wait to obtain a new APO140FL can, as this article was written, span a couple of years after ordering and this is the longest lead-time model they offer.

These telescopes have been developed with the active observer and astrophotographer in mind, with the emphasis on those things that make participation in the hobby a joy or research a success: sharp high-resolution optics, rugged and yet surprisingly compact and relatively lightweight construction, complemented by easy to use and effective accessories. Since TEC is in touch with the most demanding people, TEC has refined these telescopes over the decades. Since TEC controls all design and production in-house, they have been quick to adapt new ideas and technologies into production at a rate much faster than larger companies.

TEC refractors have come to represent a high standard for optical performance, appearance, fine mechanical design and construction, and they are compatible with the most comprehensive proven systems of matched accessories giving them great versatility. The exchanges of ideas and accessories have most notably included the Baader Planetarium, and Astro-Physics companies.

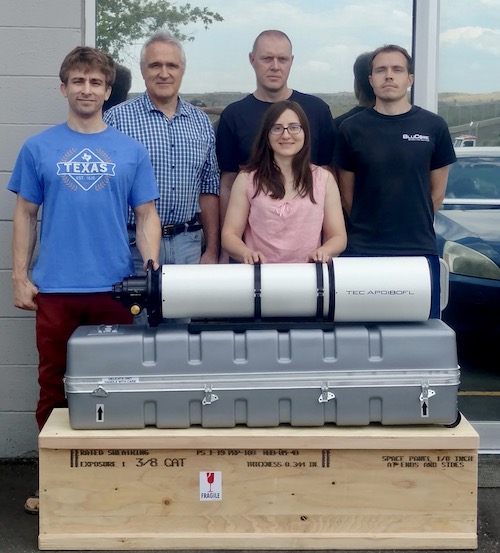

Above: TEC's team, including Yuri, standing by their APO180FL telescope with lens shade retracted.

This is set shows their lightweight carry case, and the packing crate (83,325 bytes).

In terms of cost too, we have never had it better when you consider how much of a person's annual income might have been spent to buy just a 4 inch achromatic, relatively primitive, refractor of just decades ago. In 1954 when telescopes amateurs aspired to included the Unitron 4 inch Achromatic Equatorial refractor, or Questar 3-½ the average median income in the United States was estimated to be $3,200; either of those telescope sold then for $795.00 plus tax and shipping! That is just about 25% of medium annual income. Today, with the median annual income is $54,132, that would be akin to paying $13,533 today for that comparatively primitive 4 inch achromat, or for that Questar 3-½ that have been markedly improved since 1954.

While camera lens glass technology and other refinements have led to improvements in astronomical telescopes, the rate of evolution has not been quite as rapid as they were from 1970s into the 1980s. The most notable advancements over the recent years have been in tracking mounts, where products new to our hobby (harmonic drive mounts were invented in 1957) provide that a carry-on luggage portable 'go to' tracking mount and tripod set that weighs about 17 lbs. can support a 130 to 140mm class Apo with rigidity, pointing and tracking precision good enough for imaging!

The TEC objectives are APOCHROMATIC, which means that the images are essentially free of false color, both visually and photographically, and have been figured to a very high level of perfection. Yuri has selected true synthetically grown optical grade Calcium Fluorite (the 'gold standard' in lens-making) or in some lenses Super ED glass, to be the heart of his optical designs because of their excellent light transmission and superior correction of all the monochromatic and polychromatic aberrations.

TEC optics are made of optical materials sourced from some of the finest and most consistent glass and crystal makers overseas. The TEC in-house designers and craftsmen create and match these lens elements, that have been proven to be first class. The TEC products are highly regarded not only in published reviews, but also by our own evaluations, both reinforced by the positive work published by their users and from comments by those who have lined up to look through them at public events.

TEC optics are made of optical materials sourced from some of the finest and most consistent glass and crystal makers overseas. The TEC in-house designers and craftsmen create and match these lens elements, that have been proven to be first class. The TEC products are highly regarded not only in published reviews, but also by our own evaluations, both reinforced by the positive work published by their users and from comments by those who have lined up to look through them at public events.

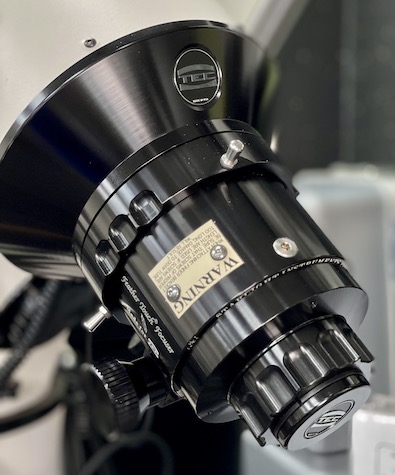

Right: business end of the

Here the dew shield is shown retracted for storage, in use this slides forward to an extended orientation.

Click on image to see enlarged view (163,234 bytes).

Most TEC triplet Apo lenses are what are termed an 'oiled' (or immersion, dating back to microscope days) lens arrangement, though some are air-spaced. Oiled lenses are joined together by a synthetic media filling the space(s) between the lenses. That media originated at the University of Jena for use in the Carl Zeiss APQ introduced in 1985 and later in Astro-Physics' first generations of EDF lenses. There is no light lost, or chances of reflections between the three lens elements. The TEC air-spaced lens elements, and the front and rearmost surfaces of TEC oiled lenses, employ state of the art lens Broadband antireflective (BBAR) coatings. BBAR coatings consist of multiple layers, each microns thin, and alternating between a high index material and a low index material. The layers are deposited via computer controlled electron-beam deposition. These state of the art coatings facilitate the transmission of light through and between the objective lenses in a manner optimized to produce superb contrast and color fidelity. Incidentally the internal radii of the immersion (oiled) lenses are not and need not be coated as there would be no benefit as any reflection by an immersion surface is much lower than even the best BBAR coated surfaces. A side benefit in production is eliminating the added, albethey modest, risks of having additional exposure to the coatings personnel and processes.

This is another of those few product lines that makes "Made In The USA" resound. The work of grinding and polishing the lenses, the lens coatings and the precision mechanical components are all entirely made by highly expert craftsmen in the USA. We invite you to visit Company Seven's showroom, the only full line Astro-Physics and TEC showroom in all the Americas (aside of the factory) where we show their product line including many other rare or discontinued telescopes and mounts.

TUBE ASSEMBLIES

The Optical Tube Assembly includes: the lens, the front cell, the optical tube, and focuser. Aside from the lens, all vital optical tube components are precision machined of lightweight metal alloys. The Optical Tube Assembly Department at TEC carefully installs the baffles within the telescope tubes to insure that the placement is precise thereby effectively eliminating stray light.TEC optical tube assembly interior features computer-aided engineered internal baffling, carefully and permanently positioned at the precise optimal location in the optical tube assembly. While their interior is fully treated in a black anti-reflection finish. Looking down into the barrel of one of these optical tubes reveals something resembling the blackness of Space with no reflections or opportunities for glare or ghost images to form.

The focuser of each TEC telescope is manufactured in the United States by Starlight Instruments; these each incorporate the latest features to insure smooth precise performance, compatibility with highly desirable optical accessories (field flattener, focal reducer, etc.), and all while assuring excellent longevity. The TEC telescope focuser is designed with the astrophotographer in mind too, each incorporates the Feather Touch dual-speed geared manual focus control. While the focuser body can be loosened, then precisely rotated around a full 360 degrees. The image at right shows the focuser's natural aluminum grip handles (to facilitate rotating the focuser body) three that are 120 degrees apart, near the knurled locking ring. These features facilitate more precise focus, and the optimal composition of the image whether at the eyepiece or a camera.

The focuser of each TEC telescope is manufactured in the United States by Starlight Instruments; these each incorporate the latest features to insure smooth precise performance, compatibility with highly desirable optical accessories (field flattener, focal reducer, etc.), and all while assuring excellent longevity. The TEC telescope focuser is designed with the astrophotographer in mind too, each incorporates the Feather Touch dual-speed geared manual focus control. While the focuser body can be loosened, then precisely rotated around a full 360 degrees. The image at right shows the focuser's natural aluminum grip handles (to facilitate rotating the focuser body) three that are 120 degrees apart, near the knurled locking ring. These features facilitate more precise focus, and the optimal composition of the image whether at the eyepiece or a camera.

Right: TEC APO180FL telescope rotatable 3-½ inch focuser, by Starlight Instruments, at Company Seven (58,791bytes).

Click on image to see enlarged view (170,099 bytes).

On the telescope there is a provision for attaching an optional Finder Telescope onto the Focuser Body. The APO180FL at right for example is shown with the warning label that comes from the factory, this is affixed with the two bolts that would usually be used to attach a finder quick release base bracket. Notice that especially on the larger telescopes there is a marked rise from the focuser body up to the level of the optical tube, conventional finder brackets will not clear this so TEC offers a bracket that is made to allow enough of a rise so that the platform will clear the optical tube, and even clears the added height of the TEC telescope OTA Mounting Rings. Company Seven offers additional services and hardware so that our clients can attach a broad variety of auxiliary finder and/or photo-guiding telescope(s).

These larger TEC focusers will include reducers down to 2 inches, and with a slip-fit TEC cover. Each can be adapted with options including motorized electronics for local or remote control, this can even be fully automated to compensate for changes of ambient temperature. Each lens cell and focuser are squared onto the tube in preparation for the final assembly and final collimation (alignment) of the telescope. The optical tube assembly incorporates a captive retractable Lens Shade/Dew Shield. This makes these state of the art very fast Apos extraordinarily compact for transport, and moderate the size of a mount that would otherwise be necessary to adequately support each telescope. Even the lens cover of a TEC is uncommonly advanced, with fingers pressing on the spring-loaded release the compression crews the locking latch so the user remove the lens cover. When the lens cover is reattached, then there is no risk of marring the dew shield edges; TEC has learned by observing many other telescopes out there too.

ACCESSORIES

TEC telescopes are complemented by a comprehensive, custom matched series of their own accessories, as well as being compatible with many Astro-Physics telescope accessories and options that make both these lines of telescopes among the most versatile. The visual or imaging accessories can include: camera adapters for CCD, DSLR, or up to medium format, or telecompressors. All have been carefully designed for functionality and compatibility by TEC or Astro-Physics, then tested and proven in the field under actual observing conditions. Most are offered at pricing that can be lower than those offered by others - and that may perform no better if as well as ours.

Company Seven Remains Special In The Amateur Community: no other retailer has a greater degree of knowledge and experience, particularly with the best astronomical refracting telescopes. Ours is among the few remaining telescope specialty retail companies operating in the Americas, also serving an international clientele. We maintain an unrivaled showroom, and provide routine evaluation and certification services for any newly arrived telescope. For the support of those astute enough to buy from us we offer a variety of services including training, and service, repair, collimation, and refurbishment services. This testing can be subjective where experienced technicians evaluate the lens on calibrated targets, and provide an opinion based on what they see. Or we can employ objective methods of testing where analysis results in documentation being provided. If packing or shipping damage, or other problems arise then we will manage the remedy for you.

So even well after the purchase if you ever find yourself in need of support or repairs for a TEC instrument you purchased from Company Seven, of course you can return a TEC product to the factory or to Company Seven, whichever is more convenient for you. For more about our services read Company Seven | Quality Control, Testing, and Certification Services, or contact us.

Contents Copyright 1994-2025 Company Seven & TEC All Rights Reserved