|

TEC REFRACTING TELESCOPES MECHANICAL ACCESSORIES

TEC 3.5 INCH FOCUSER

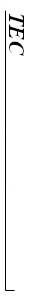

The focuser of each TEC telescope is manufactured in the United States by Starlight Instruments; these each incorporate the latest features to insure smooth precise performance, compatibility with highly desirable optical accessories (field flattener, focal reducer, etc.), and all while assuring excellent longevity. The TEC telescope focuser is designed with the astrophotographer in mind too, each incorporates the Feather Touch dual-speed geared manual focus control. While the focuser body can be loosened, then precisely rotated around a full 360 degrees. The image at right shows the focuser's natural aluminum grip handles (to facilitate rotating the focuser body) three that are 120 degrees apart, near the knurled locking ring. These features facilitate more precise focus, and the optimal composition of the image whether at the eyepiece or a camera.

The focuser of each TEC telescope is manufactured in the United States by Starlight Instruments; these each incorporate the latest features to insure smooth precise performance, compatibility with highly desirable optical accessories (field flattener, focal reducer, etc.), and all while assuring excellent longevity. The TEC telescope focuser is designed with the astrophotographer in mind too, each incorporates the Feather Touch dual-speed geared manual focus control. While the focuser body can be loosened, then precisely rotated around a full 360 degrees. The image at right shows the focuser's natural aluminum grip handles (to facilitate rotating the focuser body) three that are 120 degrees apart, near the knurled locking ring. These features facilitate more precise focus, and the optimal composition of the image whether at the eyepiece or a camera.

Right: TEC telescope rotatable 3-½ inch focuser, by Starlight Instruments, at Company Seven (58,791bytes).

Click on image to see enlarged view (170,099 bytes).

On the telescope there is a provision for attaching an optional Finder Telescope onto the Focuser Body. The APO180FL at right for example is shown with the warning label that comes from the factory, this is affixed with the two bolts that would usually be used to attach a finder quick release base bracket. Notice that especially on the larger telescopes there is a marked rise from the focuser body up to the level of the optical tube, conventional finder brackets will not clear this so TEC offers a bracket that is made to allow enough of a rise so that the platform will clear the optical tube, and even clears the added height of the TEC telescope OTA Mounting Rings. Company Seven offers additional services and hardware so that our clients can attach a broad variety of auxiliary finder and/or photo-guiding telescope(s).

These larger TEC focusers will include reducers down to 2 inches, and with a slip-fit TEC cover. Each can be adapted with options including motorized electronics for local or remote control, this can even be fully automated to compensate for changes of ambient temperature. Each lens cell and focuser are squared onto the tube in preparation for the final assembly and final collimation (alignment) of the telescope.

If you study the photos of early large refracting telescopes, most of these telescopes feature a grab handle positioned at or near the rear cell of the telescope to facilitate pointing the telescope onto target. The most popular arrangement are circular, often termed a “Captain's Wheel” owing to the similarity of these to the steering wheel of ships. This handle arrangement is convenient, and far safer than grasping in the dark at the more delicate Focuser or at attached accessories.

If you study the photos of early large refracting telescopes, most of these telescopes feature a grab handle positioned at or near the rear cell of the telescope to facilitate pointing the telescope onto target. The most popular arrangement are circular, often termed a “Captain's Wheel” owing to the similarity of these to the steering wheel of ships. This handle arrangement is convenient, and far safer than grasping in the dark at the more delicate Focuser or at attached accessories.

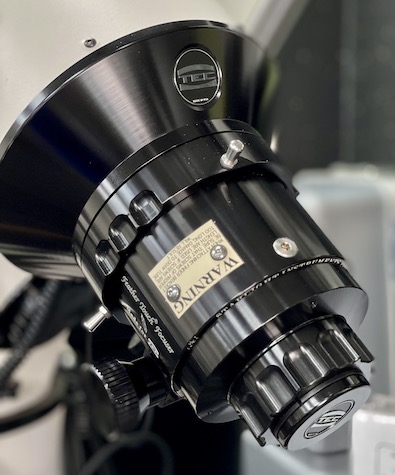

Right: TEC telescope rear cell flange with “Captain's Wheel” attached. At Company Seven (36,134 bytes).

Click on image to see enlarged view (185,364 bytes).

The focuser of the larger TEC telescopes, those with apertures of 160, 180, 200 and 250mm, produced over the recent decades* incorporate a “Captain's Wheel”. Many of the TEC telescopes made predating this feature can have it retrofitted; Company Seven can advise, and even arrange this for our customers.

-

* The rear flange of the 140mm telescopes are too narrow to accept this option.

To Wheel, Or Not To Wheel? We at Company Seven were well acquainted with these devices, they are on many of the larger observatory refracting telescopes that we have worked with. However, we were not used to seeing them on portable or trans-portable telescopes. When we first observed them being provided by TEC we honestly had mixed feelings about them:

- who needs to pay extra for that, when we can just grab the telescope at the focuser

- why would I want to add any extra weight to my telescope optical tube assembly that would just make more work, increase necessary counterweight, etc.

- it would take up extra space, maybe necessitate a larger carry case

It was only after we started to exhibit (at our Laurel, Maryland showroom) and deliver TEC telescopes that incorporate the wheel, and also receive feedback from our own customers, that we became convinced:

The TEC telescope Captain's Wheel, as are the other components of these telescopes, are manufactured in the United States. The design is excellent, affording a reliable handhold supposed by four precision machined alloy spokes that makes carrying the telescope far more convenient, while it does not add onerous weight to the telescope rear cell and focuser assembly. The outer radius conforms nicely to the diameter of a telescope optical tube and mounting rings.

The TEC telescope Captain's Wheel, as are the other components of these telescopes, are manufactured in the United States. The design is excellent, affording a reliable handhold supposed by four precision machined alloy spokes that makes carrying the telescope far more convenient, while it does not add onerous weight to the telescope rear cell and focuser assembly. The outer radius conforms nicely to the diameter of a telescope optical tube and mounting rings.

It is convenient to grasp even when wearing gloves, yet not protruding so wide that it hinders operating the refractor when pointing it towards zenith.

Left: TEC Captains Wheel installed on APO180FL rear cell flange, exhibited at Company Seven (36,134 bytes).

Click on image to see enlarged view (185,364 bytes and 264,497 bytes).

The implementation is durable and reassuring; this will not fall apart on its own. While the engineering and precise execution are sound, the high qualities of the precision-machined metal alloy, and its black anodized finish, complement the aesthetics of the telescope as well.

For those who work to bury their telescope optical tube under all manner of cabling for imaging cameras, auto guiders, robotic this and that, dew and frost prevention heaters, the wheel provides a good anchor for fastening device(s) cabling.

Because the Captain's Wheel is bolted on, it can be removed by the user if ever desired.

TEC HINGED MOUNTING RINGS

TEC offers optional Mounting Rings, sold by the pair, to attach the telescope optical tube onto the platform of a suitable mount. These are made of aluminum alloy, precision machined in the United States. The TEC mounting rings are anodized black for their 180, 200 and 250mm telescopes. Rings for the 140 and 160mm are finished with the same powder coating to match the optical tube barrel.

Fastener: their split-ring hinged arrangement features comparatively lower profile, sleekly outer radiused halves. TEC implements a fastening mechanism that is not typical of the industry; the TEC rings feature a quick-release mechanism so that it is quick and easy, even with a gloved hand, to open unlatch or latch the ring closed. The fastener mechanism is made of durable stainless steel, with a hand latch that can be snapped open to release tension on the rings. The fastening mechanism latching post effective length is adjustable, so tension holding the optical tube can be maintained. The latching post can be disengaged from the bottom ring to completely open the rings and dock a telescope optical tube into the lower half rings. Then the upper rings are pivoted down, the fastener is latched to secure the optical tube in place.

Above: TEC hinged Mounting Rings with locking mechanism fastened at left, and unlatched at right.

Exhibited at Company Seven (27,704 bytes and 30,241 bytes).

The inner radius of the rings are lined with a non-marring felt fabric, so just prior to fastening the rings halves together, the user can gently slide the telescope optical tube forward or back to attain optimal balance. So for example, should the accessories payload on the focuser change notably then the telescope optical tube with mounting rights attached to a dovetail plate could be adjusted by sliding the entire assembly forward or back, then secured in place.

Accessory Platforms: each ring features a precision-machined flat platforms at top and at bottom. These platforms incorporate holes, including one at center and four others, tapped and threaded corresponding to some popular telescope accessory hole standards. The platform at the bottom allows you to bolt the telescope directly onto a flat plate of a mount. More commonly, we attach an optional dovetail plate to span the bottom of the two mounting rings; this arrangement makes it easy to slide a telescope on to, or remove it from a mount. The dovetail plate arrangement also facilitates fine adjusting the telescope balance, to and fro, along the longitudinal axis.

Accessory Platforms: each ring features a precision-machined flat platforms at top and at bottom. These platforms incorporate holes, including one at center and four others, tapped and threaded corresponding to some popular telescope accessory hole standards. The platform at the bottom allows you to bolt the telescope directly onto a flat plate of a mount. More commonly, we attach an optional dovetail plate to span the bottom of the two mounting rings; this arrangement makes it easy to slide a telescope on to, or remove it from a mount. The dovetail plate arrangement also facilitates fine adjusting the telescope balance, to and fro, along the longitudinal axis.

Right: TEC Mounting Ring view angle showing top platform, exhibited at Company Seven (29,848 bytes).

The top flat area of the rings allow attaching accessories in what we term a piggy-back arrangement. This payload can be attached by bolting it onto the top of the ring, such as a with photo-guidescope's mounting ring. Or another dovetail plate can be attached, spanning the tops of both rings, to allow sliding a payload on or off. Extra mounting rings could be attached onto the telescope optical tube as 'hard points' at which to attach other payloads too.

Hints about using mounting rings:

- Prior to installing the telescope onto the rings, or removing it, ensure the mount in a safe configuration. For German mounts set the mount to the Pole Alignment orientation, with both Decl. and R.A. axes locked, and with the counterweights extended to the distant end of the shaft.

- Keep the telescope optical tube and the inner felt lining of the mounting rings clean; a speck of sand can be dragged along to scrape the finish of your pretty telescope. So inspect bearing surfaces for cleanliness prior to installing the telescope onto the rings, or adjusting the tube in the rings.

- To eliminate chances of chipping the finish of your telescope, when docking the optical tube into the rings keep its longitudinal axis parallel to the mounting plate supporting the rings and set the tube down gently. For longer and/or heavier, telescopes it can be best to have a helper supporting the opposite end of the optical tube.

- With the mounting rings tensioner loosened, the telescope optical tube is moved forward or back to achieve proper balancing. A gentle nudge, simultaneously accompanied with a rotating of the optical tube back and forth, can make this go easier.

- The inner radius of the ring is lined with a non-marring felt fabric, so combined with expansion and contraction properties of the metal components, tension is maintained even over normal temperature changes. Over decades of use any felt can be worn down or compressed thin. While with exposures to extremes of heat, such as in a desert observatory, the felt adhesive can break down or migrate. Should either issue crop up then is a simple matter to return the mounting rings to us for relining.

Contents Copyright 1994-2024 Company Seven All Rights Reserved