Questar Distribution

![]() News

News ![]() Notes & Interesting Articles

Notes & Interesting Articles ![]() Overview

Overview ![]() Pricing

Pricing ![]() Products

Products ![]() Service or Repair

Service or Repair

Questar Telescopes ![]() LD Surveillance Systems

LD Surveillance Systems ![]() LD Microscopes

LD Microscopes ![]() Accessories

Accessories

Early Production Questar 3-½ Telescopes: 1954 and 1955

An overview of the first production Questar 3-½ telescopes.

This article is provided as a courtesy by Company Seven for those customers who have helped to keep us in business.

The American made Questar has since 1954 been acclaimed as an elegant and refined practical tool for astronomy: the Rolls-Royce of compact telescopes. The fundamental attributes attracting such praise remains the same today as it was: performance, convenience, and reliability. The Questar is among the last of few products in production over the recent decades where no practical or aesthetic aspect has been compromised in order to cut costs. This arguably remains the best balance of essential attributes in the carry-on portable class of telescope - downright easy to set up while also rewarding to use.

Here we will look at some of the earliest Questar telescopes made, and discuss how as refinements were devised these first, or what we term 'early production', telescopes and their accessories differed from mid, later and current production models.

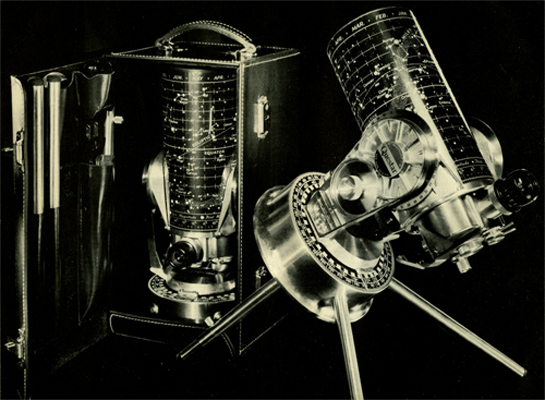

Right: early production model Questar 3-½ of 1954-1955 cased at left, and in Pole Aligned mode at right (119,017 bytes).

From the May 1954 Questar booklet available for download at our Questar Notes & Interesting Articles on line archives.

Click on image to see enlarged view (345,776 bytes). Photo from Company Seven archives.

As explained in our article How to Choose Your Questar 3-½:

-

"Aside from the quality of optics, the Questar telescopes include patented devices to insure these instruments are compact, free of periodic adjustments, and user-friendly. All of these features evolved before the now popular term "user friendly" was first uttered. These features include built-in magnification changers, an integral finderscope, extraordinarily smooth and precise focusing mechanics. All of this is may be duplicated at some cost in another telescope. However, what makes the astronomical Questar 3-½ models even more unique is their extreme portability: these are a complete personal portable and power independent tracking telescope, with six magnifications (three from each provided ocular), tabletop tripod legs, superb quality Solar Filter (one for the telescope objective, and one for the finder too) which can show an eclipse and reveal Sun spots and Faculae, all of which store under an average airline aircraft seat within a compact fitted case as shown above."

Over the first year and a half of production Questar production grew to average five or six units sold per month. Between 1956 and the middle of 1961 sales increased to average almost eighteen units per month. The number of new instruments delivered between commencing production in the first five years was doubled over the following two years. The increase of sales parallels the growing increase in space prompted by the early manned space flight missions, an increase in science education and awareness of Eclipse events, and the growing recognition that the Questar was a unique and valuable instrument.

Since its introduction Questar has been immortalized in film and in books by respected people including Johnny Carson a national television icon, and renaissance man Arthur C. Clarke who wrote "the finest small telescope ever built--the 3-½ inch Questar, a jewel of precision optics which has produced close-ups of the moon that could easily be mistaken for Mount Wilson photographs". Among three Standard Questar telescopes made for the US Army Redstone Arsenal in May 1959 was one that was used by Dr. Wernher Von Braun; this telescope remains in service with the Kennedy Space Center amateur astronomy club.

The Questar is considered such a high accomplishment that one special 1965 Questar Standard 3-½ now resides in the collection of the Smithsonian Museum of Technology in Washington, D.C.; it is a unique cut-away instrument that reveals the various innovations unique to the Questar. These basic principles of the telescope remain unchanged, even after more than sixty years in production.

Basic Configuration: the production 3-½ astronomical telescopes of the 1950’s and those of today incorporate optics that are some forms of the Maksutov-Cassegrain optical design. Drawings and prototypes were in development from 1946 until finally entering commercial production in 1954 as a variation of the Maksutov-Cassegrain design the 'Denny Triple-Passage Meniscus' arrangement. This was suggested late in 1949 by Braymer’s attorney Joseph Denny to avoid patent conflicts with established Maksutov-Cassegrain designs of the time. The design was ray traced and optimized by Braymer’s friend, optical designer Norbert Schell.

The telescope consists of the optical tube assembly incorporating a Control Box at rear, that assembly is mated to a dual tine fork mount and base. These early telescopes consisted of some 238 components, many of them unique to the Questar, provided by 103 subcontractors and suppliers. As shown to the right in the image at the top of this page, the astronomical Questar 3-½ telescopes are provided with a lightweight but rigid tripod leg set so the mount can be Pole aligned, this permits the drive to track celestial objects as they appear to move across the sky while the Earth rotates. The mount and barrel of the telescope also incorporate features to help one learn and navigate the night sky.

These first telescopes incorporate a Primary Mirror made of Corning Pyrex®. The Primary and Secondary Mirrors were coated with reflective aluminum, then overcoated with Silicon Monoxide (AlSiO) a hard protective coating to prevent oxidation of the aluminum. The thick meniscus Corrector Lens of these telescopes is made of a borosilicate crown glass. This lens and the internal optical elements in the Control Box are antireflection coated with Magnesium Fluoride (MgFl) to increase transmission by up to ninety eight percent per surface. By 1963 Questar customers would be offered the choice of either the standard Pyrex® Primary Mirror, or at extra cost the more thermally stable Quartz primary mirror substrate. By the 1970’s optional Broad Band coatings that improved throughput of the entire system would be among the available options.

As the Earth rotates about its axis the celestial objects overhead appear to move across the sky from east to west, this is an arcing motion referred to in astronomy as Right Ascension. The Questar Fork Mount and Base assembly supports the telescope rigidly, and their clutched mechanisms allow the user to grasp the telescope optical tube and point it up or down in altitude, or in astronomical terms 'Declination' motion, or left and right in 'Right Ascension'. The motions are smooth, the Declination motion can be finely controlled by rotating the manual friction drive control knob on the side of the fork. The fork Base also permits the optical tube assembly to be rotated in Right Ascension by means of the manual friction drive control knob off center on the top of the fork base.

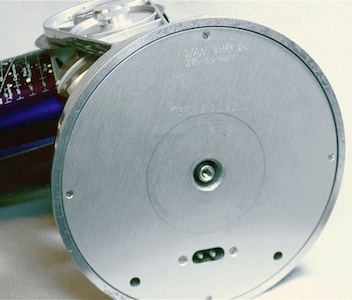

The Base of Questar 3-½ telescopes, and later the Questar 7, were manufactured over the first few decades incorporating an AC powered synchronous motor. The motorized drive provides when the telescope mount is Pole Aligned parallel to the Earth’s axis of rotation, the mount will drive the telescope to track celestial objects at a Sidereal rate; this is moving one full rotation in 23 hours 56 minutes and 4 seconds. The drive Base incorporates a A.C. (120 Volt or 220 volt optional) motor, with a power cord that plugs into a two prong male socket built into the bottom cover plate of the Base. The 2 watt motor (2.7 on later models) is ½ RPH with a sealed and lubricated gear train, these were originally sourced by Questar from Cramer Controls Corp. in Centerbrook, Connecticut. Since the rotation of the motor is not reversible, Questar provided a motor with the correct voltage and rotation to be used at the customers location either in the North or the Southern Hemisphere. For those traveling to another hemisphere the appropriate motor could be ordered and then installed with simple mechanical skills.

The provided tabletop tripod is an arrangement consisting of two fixed length legs that slide into the holes along the side of the Base casting, plus one adjustable length leg which slides into the orifice center of the Fork Mount Base. In order to align the axis of rotation of the mount with that of the Earth, one tilts the fork mount atop the tripod so that the center leg parallels the Earth’s axis of rotation and the imaginary line running through the center of the leg and up through the fork mount points to the Celestial Pole. To Pole align the mount the assembly is pivoted left or right to point the fork towards the Pole, while the length of the Center leg is adjusted, from between 10-5/8 to 18-11/16 inches, to permit the user to adjust the tilt of the Fork Mount and Base. Each leg has a protective non-marring and non-slip black rubber tip so that it will not mar a tabletop.

The two tripod leg ports on the side of the Base casting are each provided with a removable gasketed plug. These plugs each consist of three parts: the plug with gasket and a bolt so that when the telescope is set up on the provided tripod legs set the plugs can be pulled off the hole then stored into threaded sockets in the bottom of the Base. On early production Questar telescopes the bolt was blued, then in 1956 the production transitioned to stainless steel.

When properly Pole aligned and tracking then the mount’s tracking motion counters the apparent motion as Earth rotates about its axis so that these objects appear motionless and suspended in space at the eyepiece. The Questar can keep the objects in the field of view of an eyepiece or camera thereby removing the distraction and difficulty of manually trying to follow objects precisely across the sky. The tracking feature also facilitates sharing the telescope with young or inexperienced observers. The manual and mechanical mechanisms are friction drives so there is no periodic error (as there will be with worm gear drives) and this facilitates employing the telescope for astrophotography.

With the provided functional Moon Map and Star Chart on the telescope barrel and Dew Shield, and by using the Declination and Right Ascension setting circles the user of the Questar can learn much about celestial navigation, and how to find the otherwise unobservable objects that might otherwise go unnoticed. These early charts incorporated features to make the more readable in low light including embossing and texturing so that the major features into the metal covering. The aluminum stock was provided by Alcoa, not always meeting the standards required by the Metal Etching Corporation who made the star charts and moon maps. This manufacturing technique would be discontinued by the late 1960’s when the charts became silk screened. The original style embossed charts would be brought back as a feature of the deluxe 50th Anniversary Model telescopes released in September 2000.

The Declination Setting Circle is made of machined steel stock, with the degree numbers and hash mark increments engraved and painted black. The Declination Setting Circle is provided on the left side of the fork mount, the circle on the right side is a component of the elevation friction drive.

The distinctive flared cylindrical Base is cast from corrosion resistant aircraft grade virgin aluminum 356-T6 heat treated alloy then is hand turned, then machined. As 356 alloy will not color anodize this is hand polished to a pewter sheen, over time the natural metal finish can be renewed simply by polishing. As described by Lawrence Braymer:

The 5/8 inch (15.75 mm) diameter tripod legs are made of lightweight Aluminum 61 S-T3, each is centerless-ground to 0.0001" then anodized. The tripod hole plugs in the Base of Questar telescopes made from 1954 to the late 1960’s served two functions, one as hole plugs and the other as attachment screws for hanging the telescope onto a suitable panel such as a half open car window. This is a most precarious looking arrangement, but one that worked for some people for terrestrial observing. The rotating capability of the barrel allows the eyepiece to be rotated to away from the car to facilitate access. This is pictured on page 7 of the 1960 edition Questar booklet available for download at our Questar Notes & Interesting Articles on line archives.

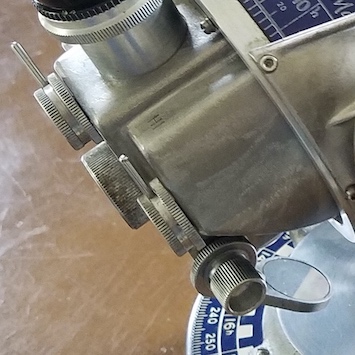

Right: left rear view of 1955 Questar 3-½ in Company Seven’s Museum Collection (103,682 bytes).

The controls and components are:

The Finder in the telescope consists of a ⅛ inch thick elliptical pick off mirror that is attached onto a 45 degree inclined support brace; this assembly is attached to the bottom of the Control Box. Light comes from the distance into the mirror then is reflected up and through the Finder Objective Lens that is installed at the bottom of the Control Box. The light is focused by this lens up and into the eyepiece Field Stop.

The early and mid production Questar telescope eyepieces are a two piece threaded assembly. The lower section threads onto the cylindrical eyepiece holder, while the eyepiece upper section (housing the optics) rides on a thread so this section can be rotated up or down to reach focus when observing through the Finder.

2. An Amici image erecting prism is built into the Control Box of these early Questar telescope. When the Finder/Telescope selection dial is rotated counterclockwise, so that the lever points up, then the prism slides into place at the center inside the Control Box so the light coming out of the telescope’s main optical tube into the Control Box is diverted up to the eyepiece. The Amici prism corrects the image orientation, so that images appear right side up and correct left to right.

The Amici image erecting prism was built only into those Questar telescopes manufactured between May 1954 to May 1959. To provide improved resolution this was changed in June 1959 so that every Control Box is provided with a Star Diagonal, a 90 degree prism, so the image at the eyepiece appears right side up but reversed left to right.

3. Also built-in to the Control Box is a magnifying (Barlow) negative lens. This can be dialed in or out by the topmost knob on the Control Box; rotate the control knob counterclockwise to move the Barlow lens off line, or clockwise to engage the Barlow when observing through the main telescope.

The Barlow is incompatible with the Finder operation, eyepieces will not reach focus with the Finder while the Barlow is engaged. Furthermore, the Barlow is intended to help attain higher magnifications (these can vary but tended to be about 1.8x then) with the two eyepieces then provided; this will not fully illuminate the field stop of most lower magnification eyepieces that came available years later.

4. The precision focus control of the main optics is an internal arrangement where the Primary Mirror is supported by a spring-loaded thimble, this assembly moves forward and back along the Primary Baffle Tube within the telescope, thus there is no change of physical length when focusing.

Right: close-up view of the Control Box of a Questar 3-½ manufactured in 1954.

The earliest Questar telescopes completed in 1954 have a focus arrangement, as shown on the original Patents, where the focus control knob is at the right side of the Control Box lower rectangular casting. This is the arrangement shown in the image at right. This orientation of the focus control did not last beyond the first year of production. We speculate this was changed because it would become awkward to reach the knob as the telescope optical tube is pointed towards the Celestial Pole where the right fork arm might hinder access. Or could this have been done to simplify production of the mechanism? For whatever reason(s), by 1955 the focus arrangement and knob location had been changed to what we are used to seeing since, with the knob below and to the right of the Axial Port. Dialing the focus knob clockwise moves toward infinity and beyond, while dialing counterclockwise moves to focus onto objects closer and closer to the telescope.

The precision machined focus knob furnished with some 1954 telescopes has a scalloped body (hollow upper cylinder) with two knurled diameters facilitating a form of coarse and fine focus control. This was changed in 1959 to a similar style knob but with a solid body and radiused top edge. The focus knob specification was changed in 1961 to the shorter button style knob, that remains in production to this day.

5. Thread on eyepiece adapter tube at the top of the Control Box. The two eyepieces provided with telescopes made from 1954 through 1972 feature a threaded rotating top barrel, this can be turned clockwise or counterclockwise to focus the eyepiece when looking through the telescope Finder. These older eyepieces were not made to accommodate a filter (color, polarizing, etc.). These also differ from modern Questar Brandon eyepieces, introduced in 1972, in that their attachment thread is narrower and not interchangeable with the eyepiece holder of modern eyepieces.

6. The Axial Port is the large female threaded opening at center of the Control Box. This accepts optional hardware including the Swivel Coupling Camera Adapter, Drop-in Filter Holder, and more. With the telescope set to Finder mode the light will pass from the main telescope tube and to the Axial Port, with the cap removed the light will continue out to an optional camera or other device.

On Questars made from 1954 to the late 1960’s this port is 0.95 inch diameter, later production telescopes will have 1.2 inch diameter ports for better performance when imaging and with some other optional accessories. We do offer adapters to permit the use of newer accessories onto the early Questar telescopes, although there may be vignetting of some modern accessories. It is possible to retrofit a new Control Box casting with the larger Axial Port, to an older Questar.

The Control Box casting of the Questars is made of an aluminum-silicon alloy, this inherently provides good corrosion resistance. And the expansion coefficients even at subzero temperatures are some ten to twenty percent lower than those of pure aluminum. The focus knob, dials and Axial Port cover are machined from aluminum 24S-T4 that is a heat treated corrosion resistant alloy, the dials feature stainless steel levers. These parts too are hand-turned on a turret lathe.

Early Production Models: incorporate a Maksutov-Cassegrain optical design that provides a nominal effective focal length of 1,070 mm at f/12. This difference between the optics of the early models and those of mid production telescopes and late production models with longer focal lengths that followed is difficult to tell simply by looking at or through the telescope.

However, those telescopes made between 1954 and into early 1956 can be most readily differentiated from the later production telescopes because of the burgundy red, silver and blue "Questar" declination axis cover plates. These are affixed to either side of the Fork Mount arms with contact cement. The plates read "42" APOCHROMAT F:12", Questar, NEW HOPE PA•U•S•A•" (yes there was a time when tangible items were made in the USA). These early discs are glued onto the ridge of the circle on the Fork Tine thus it is more likely to snag or be knocked off than the later example where the disc is glued in but recessed below the ridge level of the casting, so the mid and later production telescopes are less likely not to have lost their Fork bearing cover disc.

Looking for these covers on an older Questar is not always a reliable way to judge the age of the telescope since during the course of routine use and transport or during servicing visits these original disc could be snapped off and damaged, or for convenience they may have been replaced by a later version disc. Over the recent years we have become more careful to preserve the historic integrity of older Questars by employing time consuming methods to remove the covers but without damaging them so that the originals can be attached into place after the servicing.

The telescopes made in 1954 can be distinguished from late 1954 and 1955 production by arrangement of the Finder pick–off mirror bracket. The 1954 production employ an angled steel support to suspend the Finder mirror at the lower six O‘clock portion of the Control Box, this bracket is tilted at forty five degrees so that the image is directed from the mirror up to the Finder objective lens. This arrangement can be seen in the illustration at top right of this page.

When observing very bright objects through the main telescope optics light could be reflected from the Finder mirror up and into the telescope Control Box, this could distract the observer. So the single-arm mirror support allowed the user to swivel assembly to the left or to the right so the pick off mirror would no longer be in line with the main telescope.

However, It soon became apparent to Questar that the Achilles Heel of this otherwise durable instrument was the support bracket of the Finder pick off mirror.

So by 1955 Questar changed over to the more durable 'U' shaped finder mirror support. In this arrangement the mirror is glued onto a pivoting plate. The mirror and tilt plate are attached onto the Base of a ‘U‘ shaped steel housing by four screws, the screws adjust the tip and tilt of the mirror so that the image shown in the Finder is centered in the view through the main telescope. The entire assembly is attached to the bottom of the Control Box by four short bolts. In time Questar modified the production lacquering the steel pick off mirror housing to prevent oxidation.

The change of design of the Finder pick off mirror housing would spur the development of yet another innovation in the late 1960’s: the installation of a Solar Filter for the Finder. This Solar Filter mechanism is hinged so that the user could swing the filter element ninety degrees over or away from the Finder lens (between the mirror and the lens). By having this in place one completely eliminated the risk of accidentally switching from viewing through the main telescope with its Solar Filter attached to the Finder mode that up the then had no solar filter protection. This accessory also helps to keep the interior of the Control Box dark, free of glare from sunlight that could otherwise enter through the Finder Lens. To this day no other manufacturer has been so thoughtful to provide such a convenience built-in to their telescope!

Other distinctive aspects shared by the early production telescopes are the scalloped hand knobs attached onto either side of the Fork Mount. On these the attachment bolt at center is visible. These knobs control the elevation lock and elevation motion fine control. The knobs of Questar telescopes made since late December 1955 are similarly machined from solid aluminum 24S-T4 stock however, the center is solid and no longer scalloped as they were on the earlier production telescopes. These knobs are attached by a bolt threaded from the inner side of the fork so no attachment hardware is visible.

The Control Box casting of those Questar telescopes made from 1954 into early 1956 were delivered with a polished natural metal finish. Production models manufactured from early in 1956 to the present day will still include the Control Box however, their casting exterior is hand sanded, then primed, and then finished with a two part silver paint.

The Control Box of the the very early Questar telescopes incorporates an Amici image erecting prism so that when observing through the eyepiece the image will appear correctly oriented upright and correct left to right. The prisms originally selected by Mr. Braymer were production surplus models, acquired at a reasonable cost, and that suited their purpose in the Questar nicely. Keep it in mind that these early Questar telescopes were intended to be operated at magnifications not likely to exceed about 160x, their high magnification eyepiece with the telescope Barlow lens engaged. However, as the early stocks ran low and new prisms had to be manufactured it was found these were a costly, tedious to make component. Mr. Braymer decided to discontinue the original image erecting prism, changing this to a 90 degree prism diagonal, fully Magnesium Fluoride (MgFl) antireflection coated, that has been installed in all new Questar telescopes produced or serviced to this day.

Furthermore, years later as Questar Brandon and other third party 1.25 inch diameter eyepieces came onto the market for that are compatible with the Questar, the quality of image is superior to that of the original prism particularly when observing at the higher magnifications that the later production Questar’s are intended to attain. The sole compromise is that the orientation of the image observed through the 90 degree prism diagonal is upright but reversed left to right; this orientation is typical of what is observed through catadioptric and refracting telescopes that employ a 90 degree prism or mirror diagonal to position an eyepiece in a more comfortable position for the observer. Since quality of view is more critical to the astronomer than orientation this poses no practical issue for them, while Birders and nature observers find it is easy to adapt to the reversed left to right view or can buy an optional image erecting accessory for the axial port.

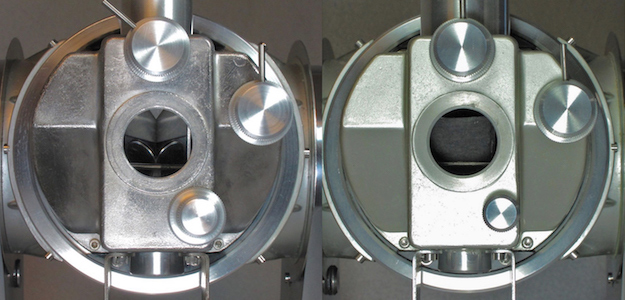

Above: at left shows a very early Questar’s Control Box with .950 inch Dia. Axial Port Cover removed, at right is that of a mid production model (61,373 bytes).

For models made from 1954 into 1956 information including the telescope Serial Number, Questar patents information, the voltage and cycles of the motor installed in the Base were hand engraved onto the cover at the bottom of the Base. This engraving is usually located between the center opening for the tripod leg and the AC wall plug socket. On these early telescopes one will read something like this:

Most AC wall receptacle and power cords in the United States of this era are a two slot socket and plug arrangement. Both of the receptacle slots and both plug blade tips too are identical in width and thickness, so a power cord can be plugged into a receptacle in either orientation right side up or upside down. The Questar was originally provided with a brown insulated, 7 amp rated AC power cord with a two prong male plug on one end, at the other is a female socket with two identical 3/32 inch (2.23mm) diameter prong holes spaced 3/10 inch (7.42mm) center to center. There is a specific flow of how the AC current runs through the wiring. One of the plug blades connects to the neutral wire socket of a receptacle, while the other blade connects to the hot wire. The hot wire carries electricity into the home and to the breaker panel, while the neutral wire carries unused electricity back to the breaker panel and out. To provide an added measure of safety for these lighter duty appliances the polarized plug and socket were developed. Questar adapted, so the later power cord and socket are polarized with tips being 7.2mm center to center with a larger 3.5mm and smaller 2.5mm prong holes and this can be retrofitted to older Questar telescopes. In fact today Questar Corp. will provide only the polarized AC cord as a replacement part, this can be sold with a new matching polarized plug socket to replace the original in the Base.

From the earliest days of production the Braymers focused on selling the Questar 3-½ telescopes into schools, focusing on the High School to College level science teaching departments; keep in mind that then (as today) these were not an inexpensive acquisition for the average amateur and the best chance to have a Questar make a lasting impression was to expose students to these instruments. Hopefully, in time these students would graduate and have the means to acquire their own telescope. Over the first year of production most of the telescopes were assigned to Questar sales representatives across the country or to schools. To this date many of Company Seven’s academic and science customers (U.S. Naval Academy, NASA Goddard Space Flight Center, etc.) own Questar telescopes that are available to staff and students either at their facilities or on a loaner basis. The telescopes are easily identified by the unique Serial Number they bear engraved on the Base Cover Plate.

Right: Base Cover Plate of a Questar 3-½ telescope made in 1970 (38,803 bytes). The Questar telescope rests on its tripod legs or on the 1/4-20 tpi threaded socket in the middle and the Base casting that surrounds the Base Plate; no load is placed on the recessed cover plate. Notice the Serial Number that was originally engraved on the Base Cover Plate cannot be read; there is no other logical reason for this degree of crosshatch wear other than for the purposeful obliteration of the Serial Number.

Unfortunately for some organizations and for many amateurs whose Questar telescope was stolen over the decades, it is a simple matter to erase visible signs of the Serial Number. Many used Questar telescopes pop up at Pawn Shops, on eBay, and other auction sites and some bear a missing or altered Serial Number with the hope that the buyer will not know to consider that. Less knowledgeable or scrupulous retailers in the astronomy community may overlook this too. Some years ago a mutual acquaintance of Company Seven and of the owner of a nearby competing telescope store bought a used Questar 3-½ there, then he brought it to us for evaluation. At first glance the Serial Number simply did not match the production era of the telescope, on closer inspection it became clear to us that the Serial Number had been altered. When we inspected production marks inside that Questar that led us the original owner, this was the University of California in Barstow. We later learned the telescope had been signed out on loan then back in to their astronomy department but in fact it had never been returned, but was sold by the person who last signed it out.

If the Serial Number is absent or altered, and if you do not wish to live under the risk of being caught with what is probably stolen property, then do not risk buying it.

The use of a Synthane backplate complicates alignment and other servicing these early telescopes since it is not practical to remove the optical tube barrel from the Synthane backplate. As mentioned above, these telescopes incorporate an image erecting Amici prism in their Control Box.

In time Questar discovered the threads tapped into the Synthane backplate wear out from the friction of the honed stainless steel threaded shaft. The wear progresses so that mirror shift while focusing becomes more and more pronounced, the smoothness of focusing degrades, and eventually the threads wear out altogether so the user can not focus until the back plate is replaced. So Questar gradually moved away from using Synthane and instead relied on machined aluminum for these components.

The accessories provided as standard with these early telescopes for $795 included:

1. 40X Eyepiece

Into 1956 the early Questars were shipped in a protective Leather Carrying Case (described below) but with no Lens Cover since it was assumed the case could provide satisfactory protection of the Corrector lens. The only provided accessory for the front of the telescope was the Solar Filter (shown above at center) that snapped into place held by three gasketed tabs pressing against the Synthane front cell’s inner radius. Questar changed the design of the optical tube front cell so that the 95 mm diameter radius was threaded to accept a new lens cover or the provided revised Solar Filter. Questar simultaneously devised a thread on Lens Cover to protect the Corrector Lens of the telescope. The lens cover was made with the black disc made of the lightweight Synthane material with a lightweight aluminum alloy edge trim glued onto the Synthane. The center is covered with a Questar logo disc glued into place.

The fork tines of early to mid production Questar telescopes feature gloss reflective polished edges with the recessed areas on the face of the fork tines painted silver. By the mid 1980’s the quality of the castings being provided caused the company to change from polished edges to a fine vertical milling that leaves a satin appearance.

As mentioned above, the early production Questars like this one also have an etched and filled Moon Map, Star Chart, and Right Ascension Setting Circle instead of the silk screened versions produced for later production units.

Eyepieces and Magnifications: these telescopes were engineered to accept either of two provided eyepieces, each is an assembly with a male thread of 1.175 inch (29.85 mm) diameter. The knurled upper assembly of the eyepiece houses the optical elements and the eyepiece Field Stop. The eyepiece threads onto the telescope eyepiece holder atop the Control Box. One dials the two Control Box knobs to allow the eyepiece to view through the Finder, then rotates the knurled upper assembly clockwise or counterclockwise to bring the Field Stop closer to or farther from the Finder’s objective lens until focus the object of study is sharp and clear.

The eyepieces provided with new Questar telescopes produced from 1954 through mid 1973 are:

1. 40X a 26mm König lens design with a 50 degree apparent field of view (measured by Company Seven as having a 18mm Dia. Field Stop), and

2. 80X a 12mm Erfle a five element wide angle lens claiming a 75 degree apparent field of view (16.6 mm Dia. Field Stop).

The Questar telescope eyepieces provided from 1957 to 1973 are labeled "40-80X" or "80-160X" to make it more clear these can be used with the Barlow Lens dialed in line or out. Of course it is possible that owners bought used older eyepieces to replace lost newer ones or vice versa, so eyepiece labeling alone cannot be counted on to date a Questar.

Those eyepieces provided with the Questar telescopes delivered from 1954 through 1973 were made by Toyo Jitsugyo KK, an optical company established in 1947 in Japan. Those made through 1956 bear no markings to indicate maker, or country of origin. The eyepieces made from 1956 will bear the engraved code mark "B.O.L. JAPAN"; this refers to an arrangement the manufacturer established between Oriental Trading, the export division of Toyo Jitsugyo KK., with Bushnell Optical Laboratory Inc. then based in California. These eyepiece do not bear the diopter indicators of the original eyepieces, the barrels of these eyepieces are finished in black paint.

The eyepiece could have been provided from the factory with the option a crosshair reticle ('+') pattern spanning edge to edge) installed. The black cross-hair is and glass thread on or off, positioned in place of the field stop.

The early Questar 3-½ telescopes were equipped with eyepieces to reach magnifications of up to 160x, though they are capable of higher. The optical design of these original telescopes and some other factors too produced a system that is good; under a critical star test a well adjusted early Questar can show a nice diffraction pattern since the optics shop making the optics then (as now) hand matched each set of optics to assure nominal figuring. Late in the 1960’s the design of the optics was changed, overall specifications made more stringent, and improved materials and coatings offered. These changes along with new choices of eyepieces would provide the later production telescopes with truly amazing higher magnifications and brighter performance.

The case is designed to hold the Questar telescope with all its standard accessories. The accessories provided with the telescope are stored in leather pouches sewn onto the interior of the door lid. This arrangement is illustrated by the image at the bottom right of this article.

Right: Original Questar Leather Case in Company Seven’s Museum Collection (74,161 bytes).

The case is laid out well and is compact, light weight (especially compared to modern Questar cases), and is beautiful. There are some aspects that are unusual:

The door lid is secured by two nickel plated steel spring loaded keyed laches, each cases included two keys. The lock hardware was made by C.W. Cheney And Son Ltd., a famous maker of locks, keys, hinges, and other hardware. Cheney was established soon after World War I, based on Factory Road in Hockley, England but has since been acquired by other companies, moved from Factory Road after 2001, and little remains with the qualities of what they made in the era of the Questar cases. Do keep in mind these locks only serve to keep the honest person honest; anyone who really wants to get in can handily walk off with the Questar in the case and force these latches to the breaking point.

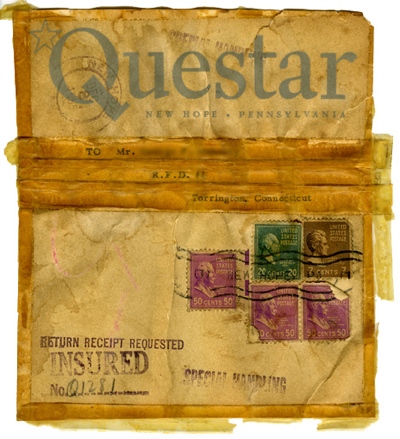

Right: the shipping label, complete with postage, of our Questar SN 105. The Postmark of the New Hope Post Office is dated 8 December 1955. For privacy we have blurred the recipient’s name.

First Class mail rates remained at 3 cents for a one ounce letter from July 1932 until August 1958. So the cost of postage for sending this Questar to its original owner in 1955 amounted to $1.77, as can be seen on the image of the original address label this was made up with three 50 cent stamps, one 20 cent stamp and one 7 cent stamp. This included basic postage for delivery, insurance for the full value of the telescope, return receipt including the 3 cent stamp for the return receipt card.

A common measure of inflation in the U.S. is the Consumer Price Index (CPI), which has a long-term average of 3.1 percent annually, from 1925 through 2008. Adjusted for inflation the postage charged $1.77 in 1955 should be about $14.26. But of course gasoline then only cost 29 cents per gallon so it is not entirely fair to expect the modern Post Office to deliver a new Questar based these figures.

What is most amusing about these labels is how they, as does the Questar telescopes described here, reflect America at an entirely different time when life was affordable on a one income earner’s salary.

Right: carrying case interior arrangement with standard accessories: Solar Filter, Aperture Stop, 40X Eyepiece (the shorter of the two) is installed, the 80X Eyepiece is stored in case lid pouch, AC Power Cord (wrapped as provided), Tabletop Tripod Leg set. The keys and a spline wrench are in the pouch (84,199 bytes). Telescope is shown at Company Seven’s Museum Collection.

Above: Questar 3-½ from 1955 in Company Seven’s Museum Collection (89,694 bytes).

Click on image to see enlarged view (125,004 bytes).

Control Box: the Questar patented Control Box at the rear of the optical tube assembly is among the distinguishing features of the Questar. This houses a series of control dials, linkages and optical components that make the Questar easy and convenient to use.

Click on image to see enlarged view (301,891 bytes).

1. The Finder/Telescope selection knob is set to divert light from either the Finder or the main optics of the telescope up to the eyepiece. This knob is the one to the right of the axial port at the rear of the Control Box. When the knob is dialed out (clockwise) this permits the user to observe through the Finder, or dialed counterclockwise to observe through the telescope.

Note the Focus dial position with original style knob, the Finder pick-off mirror with its single arm support bracket attached below.

Click on image to see enlarged view (114,237 bytes).

Above left: Fork Arms Declination axis bearing cover disc provided on instruments made from 1954 to early 1956 (30,306 bytes).

Right: Cover, with the QUESTAR star logo as provided over the Fork Arms elevation (Declination) axis hubs of telescopes from early 1956 to well into 1963 (83,529 bytes).

The very earliest Questar telescopes are distinguished by their polished Control Box housing, these were not painted. Furthermore, the very early production

telescopes incorporated the Image Erecting Prism. One can discern whether or not their Questar has the Image Erecting Prism by 1. the image orientation

observed through the instrument is correct left to right and right side up, or by 2. looking into the Axial Port to see if theirs has the Image Erecting Prism.

Click on the image above to see enlarged view (193,183 bytes).

These early production Questar telescopes incorporate some components made of Synthane, a dimensionally stable and lightweight Bakelite tube made by the Synthane Corporation. Synthane sheets consist of a laminate of fibrous sheet materials such as cellulose or asbestos paper, or a cotton or asbestos or glass fabric, saturated with a thermo setting resin. This is cured over time under high temperature and pressure. These components included the Corrector Lens front cell, the optical tube assembly backplate (the wall between the Control Box and Optical Tube in the area of the Primary Mirror), and for the earlier production models the Cover Plate at the bottom of the Base is also of Synthane.

These early production Questar telescopes incorporate some components made of Synthane, a dimensionally stable and lightweight Bakelite tube made by the Synthane Corporation. Synthane sheets consist of a laminate of fibrous sheet materials such as cellulose or asbestos paper, or a cotton or asbestos or glass fabric, saturated with a thermo setting resin. This is cured over time under high temperature and pressure. These components included the Corrector Lens front cell, the optical tube assembly backplate (the wall between the Control Box and Optical Tube in the area of the Primary Mirror), and for the earlier production models the Cover Plate at the bottom of the Base is also of Synthane.

U.S. PATS.

2,649,791

2,670,656

+PATS. PEND.

115V, 60~A.C.

Click on image to see enlarged view (248,727 bytes).

2. 80X Eyepiece

3. Velvet-lined English cowhide Carrying Case with two keys

4. Questar Tabletop Equatorial Tripod Legs

5. Questar AC Power Cord

6. Questar Off-Axis Solar Filter

7. Questar Bristol Wrench

8. Questar Booklet

9. Questar Owners Manuals

10. A letter of gratitude usually signed by Lawrence Braymer, the founder of Questar

11. Leverpak shipping drum.

The Questar telescopes delivered well into 1957 were provided with eyepieces labeled simply "40X" and "80X". The magnification is engraved onto a black plastic eyecup that is threaded onto the barrel of the eyepiece;. The original eyepieces also feature engraved white inlaid vertical diopter lines with numerals indicating from 0 to +2, and to -4. The metal hardware of these early eyepieces is anodized black.

* the Barlow lens built into the Control Box of the telescope was represented as providing an amplification factor of about 2X*. Over decades of acceptance testing new and older Questars at Company Seven, we find the effective Barlow magnification could vary higher or lower than 2X from production lot to lot.

English Leather Case For Questar 3-½: among the accessories that distinguished the Questar was the custom fitted rigid case provided as a standard accessory with each new astronomical telescope. The Questar telescope slides into the larger portion of the case, while the door interior has pouches sewn in to accommodate those accessories that were provided with the Questar. The case is made in England of two ply stitched Saddle Leather, with the interior fully lined in velvet. The leather is pliable and without any additional interior bracing, yet it is rigid enough to retain its shape and hold the seven pound Questar 3-½ safely in transit. The Questar literature of the period describes the provided case as:

English Leather Case For Questar 3-½: among the accessories that distinguished the Questar was the custom fitted rigid case provided as a standard accessory with each new astronomical telescope. The Questar telescope slides into the larger portion of the case, while the door interior has pouches sewn in to accommodate those accessories that were provided with the Questar. The case is made in England of two ply stitched Saddle Leather, with the interior fully lined in velvet. The leather is pliable and without any additional interior bracing, yet it is rigid enough to retain its shape and hold the seven pound Questar 3-½ safely in transit. The Questar literature of the period describes the provided case as:

"FINEST BRITISH COWHIDE, each one made by hand for us in Staffordshire, England. Deep luggage tan color, fully velvet lined in old wine color, leather pouches for accessories. Conservative white stitching, two locks. Rim of Questar’s Base held in case by adjustable eccentric Synthane disks."

Click on image to see enlarged view (236,042 bytes).

Leverpak Shipping Drum: since 1954 the Questar telescopes have been shipped from New Hope, PA safely packaged within it’s provided carrying case and this within an outer packing drum. The drum design was patented by Leverpak in the 1930’s and it continues in production to this date with little obvious changes. The 16 inch diameter x 22 inch tall (17-½ gallon capacity) drum features a surprisingly low tare weight combined with high payload and weight bearing capacity, and a steel top and band with lever locking mechanism. The unique Lok-Rim® closure allows easy opening and closing and has a tamper evident sealing feature.

Leverpak Shipping Drum: since 1954 the Questar telescopes have been shipped from New Hope, PA safely packaged within it’s provided carrying case and this within an outer packing drum. The drum design was patented by Leverpak in the 1930’s and it continues in production to this date with little obvious changes. The 16 inch diameter x 22 inch tall (17-½ gallon capacity) drum features a surprisingly low tare weight combined with high payload and weight bearing capacity, and a steel top and band with lever locking mechanism. The unique Lok-Rim® closure allows easy opening and closing and has a tamper evident sealing feature.

Postage: we at Company Seven are frequently amused to meet people who have kept virtually every shred of paperwork that ever was involved with their early production Questar telescope. Maybe the kind of person who was more likely to by a Questar in the 1950’s was more meticulous? After all $795 in 1954 adjusted merely for inflation alone would be in 2010 some $6,400. So it came as not too great a surprise to find the original shipping labels with postage affixed included with some of these old telescopes that we have acquired.

Postage: we at Company Seven are frequently amused to meet people who have kept virtually every shred of paperwork that ever was involved with their early production Questar telescope. Maybe the kind of person who was more likely to by a Questar in the 1950’s was more meticulous? After all $795 in 1954 adjusted merely for inflation alone would be in 2010 some $6,400. So it came as not too great a surprise to find the original shipping labels with postage affixed included with some of these old telescopes that we have acquired.

In Company Seven’s Museum Collection (74,161 bytes).

Questar Telescope Specifications 1955

Questar Telescope Specifications 1955

Telescope Clear Aperture

3.55 inch / 90.24 mm

Effective Focal Length

42.13 inch / 1070 mm f/12

Barlow Amplification

1.78x

Telescope weight (with 40X eyepiece)

6 lb. 9.1 oz. / 2.978 kg.

Tabletop tripod leg set weight

6.0 oz. / 168 g

Carrying Case Dimensions

7-½ inches deep x 7-¾ wide x 14-½ tall

190 x 210 x 368 mm

Origin

Made in the USA

Click on image to see enlarged view (273,866 bytes).

We invite you to visit our showroom near Washington, D.C. to see a Questar first hand or contact us by E-mail to info@company7.com, or by telephone 301-953-2000. The showroom is open Monday to Friday 11 am to 6 pm, Saturday 11 am to 5 pm. We are closed on Sundays, on U.S. Holidays, and from 25 December through 1 January inclusive.

![]()

Contents Copyright 1954-2020 Company Seven, All Rights Reserved