C-7 Home Page ![]() C-7 News

C-7 News ![]() Consignment

Consignment ![]() Library

Library ![]() Products & Services

Products & Services ![]() Product Lines

Product Lines ![]() Order

Order ![]() Search C7.com

Search C7.com

Losmandy Overview ![]() Distribution

Distribution

![]() News

News ![]() Notes & Interesting Articles

Notes & Interesting Articles ![]() Pricing

Pricing

![]() Products

Products

LOSMANDY HGM TITAN GERMAN EQUATORIAL MOUNT

'Go To' Computer Controlled Mount

Since its introduction in the Spring of 1992 the Losmandy Model G-11 German Equatorial mount has come to represent the best value in its class and a particularly attractive choice for those who require a high degree of tracking precision and reliability. The G-11 has been improved over the years so that it presently provides payload capacities of up to 6 inch refractors, or up to 12 inch aperture Schmidt Cassegrain telescopes. There are people who consider even larger telescopes to be "portable" and so for those people who seek a platform engineered for telescopes such as the Celestron C-14, and Astro-Physics 10" Mak, Losmandy developed the HGM Titan announced in October 2002. These mounts are fully machined from virgin metals stock on precision Computer numerical control (CNC) milling machines in California. In spite of other mount encroaching the market that claim similar payload capacities, no other mount in this price class provides this balance of payload capacity, low periodic error control, reliability, serviceability; Company Seven views the Losmandy mounts as being among the least expensive truly precision-made tracking platforms of their class. Furthermore, the Losmandy mounts and their operating systems have been so popular for nearly two decades that there is a large installed user base of accomplished users; we are confident there will many sources of parts and advice for years to come.

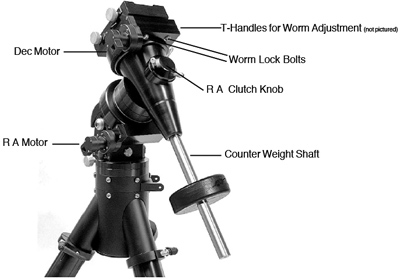

Right: Losmandy Titan Mount Head with Tripod, 21 lb. Counterweight (63,202 bytes).

Click on the image to see enlarged view (202,044 bytes).

At first glance the resemblence of the Titan to the larger HGM-200 mount is obvious The Titan appears to be a scaled down HGM-200. But this is a mount that was engineered from the ground up to take advantage of the dramatic developments in mount drive corrector and computer control technology. In fact this mount is available with only the proven Losmandy Gemini 'Go To' computer control system. As has been the case with most Losmandy mounts, it is a valuable asset that the Titan too is a mount among the few high performance platforms whose components are modular, symmetrical, and fairly simple to service or replace in the field. Our experience is that there is rarely a need to return a head to the USA for service, even more so since Company Seven technicians put in about four to five man hours checking through and fine tuning each new Losmandy mount which we receive. You are not likely to encounter any defect that would require a return of the head sold by Company Seven for service.

An equatorial mount is judged by it payload capacity and tracking accuracy. Payload ratings of mounts vary in the manner with which the manufacturer judges their product, so this number alone may not be a consistent predictor of capacity. What is most important to the user of the product is how rigidly the mount holds the payload, how smoothly it tracks (amplitude and smoothness of the periodic error of a gear), and how it overcomes the moment imparted by the load. The weight put onto the mount will vary depending how the instrument is to be used too for example one telescope used for visual work only may be as much as fifty percent lighter in weight than another employed for imaging (with guide scopes, cameras, filter wheel, etc.). The potential loading on the mount may also vary with local winds so even a mild wind accross the "sail" area of a large reflecting telescope can dramatically increase the effective load imparted to the mount. So a small mount operating from within a shelter (such as a dome or shed) with a short and narrow telescope might perform as well or better than a larger mount outside a sheltered environment. Indeed, some people elect to buy a smaller mount and then put the balance saved by not buying a larger mount into a shelter.

An equatorial mount is judged by it payload capacity and tracking accuracy. Payload ratings of mounts vary in the manner with which the manufacturer judges their product, so this number alone may not be a consistent predictor of capacity. What is most important to the user of the product is how rigidly the mount holds the payload, how smoothly it tracks (amplitude and smoothness of the periodic error of a gear), and how it overcomes the moment imparted by the load. The weight put onto the mount will vary depending how the instrument is to be used too for example one telescope used for visual work only may be as much as fifty percent lighter in weight than another employed for imaging (with guide scopes, cameras, filter wheel, etc.). The potential loading on the mount may also vary with local winds so even a mild wind accross the "sail" area of a large reflecting telescope can dramatically increase the effective load imparted to the mount. So a small mount operating from within a shelter (such as a dome or shed) with a short and narrow telescope might perform as well or better than a larger mount outside a sheltered environment. Indeed, some people elect to buy a smaller mount and then put the balance saved by not buying a larger mount into a shelter.

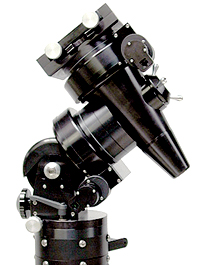

Left: Losmandy Titan Mount Head (59,558 bytes).

Click on the image to see enlarged view (131,837 bytes).

It is expected that mount in this performance class should track very well, it should suitable for the most demanding astrographic applications. This can be quantified by measuring the amplitude and smoothness of the periodic error of a gear. The period of the Titan Worm Gear is 5.3 minutes. By measuring the up and down motion of a star being tacked over this period we can measure this error. The typical Titan delivered by Company Seven will have 8 Arc. Secs. or less of periodic error (peak to peak); the tracking precision of the Titan is among the best in its price class. The amplitude is reached over a broad smooth period, not jerky or rapid. When one employs the Periodic Error Control circuit (of the Gemini), specialized software ("PemPro" for example), or guides the mount with an automatic CCD system then this error can be reduced to much less to something on the order of 2 Arc. Secs. or less. Note when using the mount with an autoguiding CCD we teach our customers to turn off the PEC.

As mentioned above, Titan includes the Gemini 'Go To' computer control system. But for use on Titan the R.A. and Decl. drive motors are the Swiss made Maxon. This is an upgrade over the standard motors provided with the Gemini systems of the smaller GM-8 and G-11 mounts. The Maxon motor provides:

1. Standard motors employ three magnets and provide three poles parallel to the shaft. As you manually turn the motor shaft you can feel a pulsing three times per revolution with the standard motors. The Maxon motor has nine poles furthermore, these are not just parallel to the shaft but are spun to form a helix around the shaft. So when the Maxon motor turns one is less likely to feel any pulse, the motor has a a lower frequency vibration and this can be seen visually as improved fine detail on planets for example.

2. The Maxon motors provide an increase of 30 per cent torque over the standard motor. These motors can run the mount better at 12 volts (by cutting top end slew rates) and better at 18 volts than the standard motor.

Company Seven offers the Titan with a 'Delete Tripod Option'. If you choose to buy the Titan mount without the standard field tripod then you may deduct $200 from the cost. It is noteworthy that this deletion of a tripod is likely to notably cut shipping costs for overseas customers.

- All machined mount made from stainless steel and aluminum bar stock

- Rated payload capacity of 100 lbs.

- Right Ascension and Declination Worm Gears are each 6.750" Diameter, 270 tooth, of 7075 Aluminum

- Heat Treated and Precision Ground Stainless Steel Worm Gears,

each dual supported by Ball Bearings assuring +/-5 Arc Second Tracking or better - Single piece worm housing construction, double ended, ball bearing supported with adjustable preload

- Fully enclosed R.A. and DEC. Worm and Worm Gear.

- Low temperature operation down to -55 degrees F (-48 C)

- Removable counterweight shaft, 1.25" diameter

- Shafts are 1.968" diameter stainless steel tubing, 0.250" wall thickness.æ

- 5.062" diameter needle thrust bearings.

- 3.500" diameter sealed ball bearings.

- 3.100" diameter sealed ball bearings for worm gear.

- Variable slip clutch, 6.0" diameter both axes, one knob design.

- Altitude and azimuth fine positioning adjustments for quickly and

accurately zeroing in on the Celestial pole in the field

- Fully locking, unique tangent arm design altitude adjustment, 12 to 70 degrees, large knob for easy alignment.

- Single knob azimuth control, bi-directional +/- 10 degrees

- X and Y axis bubble level

- Laser engraved latitude scale in 2 degree increments

- Split dovetail saddle plate design so dovetail plate drops in and locks

allowing quick interchange of poayload and reducing the need for DEC. weights. - Losmandy Gemini 'Go To' Compter Control system

- Two 21 lb. counterweights are provided

- Available with our without Semi-Pier Tripod of machined aluminum with removable legs for easy transport

- 7 lb. (3.2 kg) counterweights

- 11 lb. (5 kg) counterweights

- Off axis Pole Finder telescope for use in Northern and Southern hemispheres

- Tripod of Semi-Pier design, removable adjustable height legs.

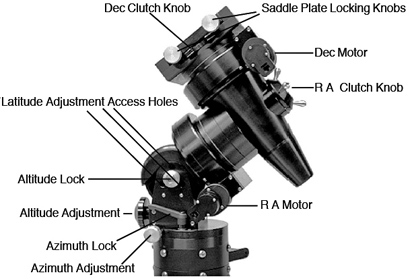

Above: Losmandy Titan Mount Head Arrangement.

Click on the images to see enlarged view.

Popular Options Include

| SPECIFICATIONS OF TITAN MOUNT SYSTEM | |

|---|---|

| R.A. Gear Wheel: | 6.7500", 270 tooth 7075 T35 aluminum |

| DEC. Gear Wheel: | 6.7500", 270 tooth 7075 T35 aluminum |

| DEC. and R.A. Worm gear: | 440C Stainless (54 Rockwell hardness) |

| Worm Gear Support: | Dual supported ball bearings |

| Preload: | Adjustable |

| Worm Gear Period: | 5 minutes 20 seconds |

| R.A. Axis Needle Thrust Bearings: | 5.062" Dia. needle thrust, 3.500 ball |

| DEC. Axis Needle Thrust Bearings: | 5.062" Dia. needle thrust, 3.500 ball |

| DEC. and R.A. Clutches: | 6.0" Slip clutch, variable friction, one knob ea. axis |

| Latitude Working Range: | 12 to 70 degrees |

| Azimuth adjustment range: | + or - 10 degrees |

| Dovetail Saddle Plate: | 1.00 x 6.00 x 8.00" Split Saddle |

| Dovetail Male Plates: | D Series |

| Mass of Equatorial Mount Head | Approximately 84 lbs. |

| Load Capacity: | Approximately 150 lbs. |

| SPECIFICATIONS OF TITAN MOUNT TRIPOD | |

|---|---|

| Construction | All machined aluminum, black anodized. |

| Semi-Pier Tripod Height | Adjustable 33 to 53 inches (84 to 135 cm) |

| Semi-Pier Diameter | 7.00 inches (17.780 cm) |

| Leg Diameter | 3.50 inches (17.780 cm) |

| Weight | approximately 66 lbs. (30 kg) |

Contents Copyright 1994-2007 Company Seven - All Rights Reserved