Unitron Notes & Interesting Articles Index

Unitron Model 132 4 inch (102mm) Equatorial Refractor Telescope

“among that class of the larger ’telescope-looking telescopes’ that many of us thought we’d never realize”

-

A discontinued product, posted for information purposes by Company Seven and with a historical perspective about the company who made it.

The Unitron illustrations here are from literature and of the telescope in Company Seven’s museum collection.

Preface:

Preface:

In August 2014 Company Seven acquired the Unitron 4 inch achromatic refracting telescope that is now exhibited at our showroom and featured in this article. The instrument was acquired from Xavier Debeerst, a collector and amateur astronomer in Belgium who owns the Arcturus Observatory and Anamorfose Curiosa, specializing in fine photographic art and collectables. He has much first-hand experience with these telescopes having amassed a collection of them, most just as they were distributed in parts of Europe under the trade names Unitron, Polarex, or Weltblick. Fluent in several languages and well traveled, Mr. Debeerst provided not only much of the hardware we describe here but he also helped us to better understand how they were distributed in Europe. The set was packed professionally, then sent by Federal Express Priority Air to Company Seven. This is among several used or consigned Unitron telescopes that have crossed our threshold over recent decades, but this is only the third, and so far the most imposing, of the Unitron telescopes to be selected for permanent retirement to our exhibit joining our Unitron Model 114 2.4 inch (60mm) Alt-Azimuth and Unitron Model 142 3 inch (75mm) equatorial telescopes. In July 2015 we added a

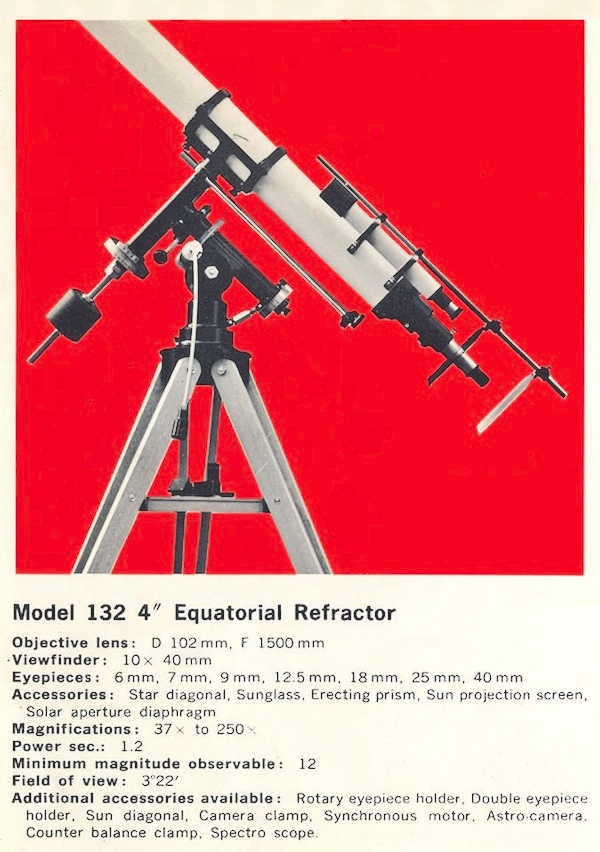

Right: Unitron Model 132 4 inch Equatorial Refractor telescope acquired in 2014 for permanent static display at Company Seven (128,015 bytes).

Exhibited alongside our Unitron Model 142/145 3 inch (75mm) telescope for comparison. Note the ceiling here is 9-½ feet (2.9 meters) tall.

Click on image to see enlarged view (216,475 bytes).

These elegant telescopes came to epitomize all that was great about traditional achromatic refractors - and all their shortcomings too. But these remained the class of well made telescopes that many purists, those who could afford them, aspired to use and admire. These telescopes remained in production and with very few changes from 1951 through 1992, by then these optical dinosaurs had been displaced from the marketplace by the more recently developed superior and more versatile apochromatic refractor and alternative telescopes.

This article is substantially similar to that which we wrote describing the

Why? for decades Company Seven has been on a mission to promote science education through astronomy. We do this subtly by helping to develop and sustain regional astronomy clubs, by donating equipment and expertise to start new astronomy programs overseas for elementary and junior high school age children, and locally with our own observatory and showroom. We conserve and exhibit telescopes and other instruments that have been worthy of note for attracting youth to astronomy, particularly since the beginning of the Space Age. Company Seven had been keen to acquire some Unitron telescopes for our display since these are among those landmark production telescopes that gave thousands of people their introduction to visual astronomy.

Our Unitron Model 114 2.4 inch telescope on the simple Alt-azimuth mount represents the pinnacle of that class of small refracting telescopes. It was among the best that a beginning amateur throughout the 1950’s and into the 1960’s might have aspired to own. Our larger Unitron Model 142/145 3 inch photo-equatorial telescope represents the most practical and versatile of the Unitron portable equatorial telescopes. This is as much at home outdoors under the night sky and yet is not overwhelming if left assembled on static display in a home. But it is our

The larger telescopes were ill suited for transport and did not fit (set up) in a typical room owing to their exceeding the height of most home ceilings, and so these were more likely to be dedicated to permanent installations at an observatory. At Company Seven our ceilings can accommodate much larger telescopes, so we display or store several Carl Zeiss and other refractors, we also show modern state of the art apochromatic refractors up to the Astro-Physics 206mm (8.15 inch) for comparison.

- Manual geared controls facilitate tracking celestial objects by turning only one control rod as, owing to the rotation of the Earth, the objects appear to move across the night sky. This is less distracting than operating an Alt-Az mount that must be continuously moved in two directions (altitude and azimuth) to keep on a celestial object of study. The tracking gear of the German Mount can be motorized, this automation permits the continuous tracking of celestial objects with precision good enough to allow photography of the objects or other projects that require keeping the telescope optical tube precisely pointed onto the target over time.

When the telescope mount is motorized and tracking a celestial object, then the user can conveniently refer back and forth from the eyepiece over to star charts or guide books and without the distraction of having to maintain a telescope centered on the object of study (as would be the case with an Alt-Az mount). It is easier to share a telescope with others over an observing session, particularly when they are inexperienced with the operation of mount manual controls. It becomes effortless to share the telescope when the mount is motorized and tracking objects automatically.

- The capability to vary the payload on the mount over a greater span than the alt-azimuth mount by simply adjusting the quantity of and position of counter weight on the shaft that extends from the mount on the side opposite the payload.

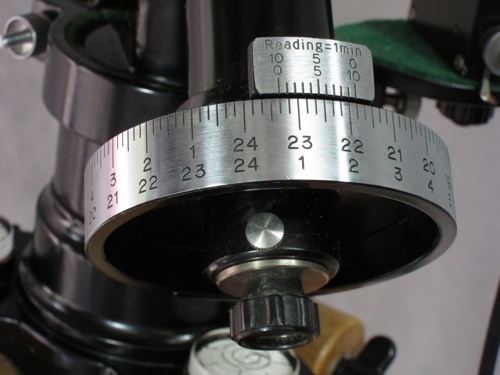

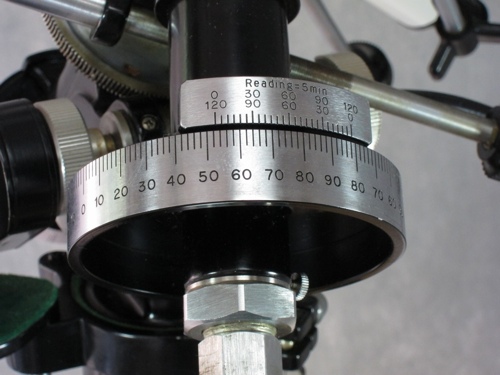

- Facilitates finding celestial objects in the telescope by means of the provided setting circle and vernier sets. These are an aid to celestial navigation whose moving numbered dials correspond to the two dimensional grid system, Declination and Right Ascension, that depicts the night sky.

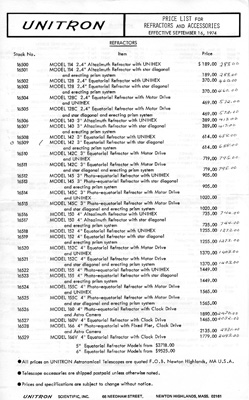

- Cost of a new Unitron Model 114 - 2.4 inch telescope with simple Alt-Az mount = $125

- Average cost of rent per month was $80.

- The average cost of gasoline was 20 cents per gallon.

- Average cost of a new car was $1,700.

- The median family salary (wages before taxes) per week was $75.

- Cost of a new Unitron Model 142 - 3 inch Equatorial Refractor telescope = $435 ($3,881.60 in 2014 per CPIIC)

- Cost of a new Unitron Model 145 - 3 inch Photo-Equatorial Refractor telescope = $550 ($4,907.77 in 2014)

- Cost of a new Unitron Model 132/152 - 4 inch Equatorial Refractor telescope = $785 ($7,004.73 in 2014)

- Average cost of rent per month was $88.

- The average cost of gasoline was 22 cents per gallon.

- Average cost of a new car was $2,100.

- The median family salary (wages before taxes) per week was $85.60

- Easy Payment Plan: was a form of credit granted to customers who completed a simple credit application and were qualified by Unitron. These customers placed their order for a telescope accompanied with a minimum payment of 25 percent of the balance due. Optional accessories amounting to $50 or more could also be bundled into this payment plan. The customer received the telescope and accessories, then paid the balance due plus a 6 percent carrying charge over the next 12 month period. Customers who could pay the balance due in less than 12 months would receive a proportional refund of 4 percent of the original carrying charge. The first payment was due 30 days after the instrument was delivered, and if the customer sent payment for the remaining balance then no carrying charge would be applied at all.

As explained in the 1956 catalog “If your choice is the UNITRON Model 152, the 4” Equatorial priced at $785, the required down payment is only $196.25 with 12 monthly payments of $52.”

- Layaway Plan: the customer ordered the telescope but the order was held at Unitron. In the meantime the customer made payments (at least $10 each in the 1950’s) and when the total had been paid then the telescope would be sent to the customer. Aside from the cost of the equipment and shipping there was no additional interest, carrying charges or fees.

- 2 inch diameter eyepiece can show as much as 2.9x the area seen in a 1.25 inch eyepiece, or 5x the area of a 0.965 eyepiece

- 1.25 inch diameter eyepiece shows 1.7x the area of a 0.965 inch eyepiece

- 0.965 inch eyepieces can show almost two thirds the area that can be seen in 1.25, and one fifth the area that can be seen in 2 inch eyepieces

- 1951 United Trading Company, 204 Milk Street, Boston 9, Massachusetts

- 1952 UNITRON, United Scientific Company, 204-206 Milk Street, Boston 9, Massachusetts

- 1957 UNITRON Instrument Division of United Scientific Co., 204-206 Milk Street, Boston 9, Massachusetts

- 1960 UNITRON Instrument Company, Telescope Sales Division, 66 Needham Street, Newton Highlands, Massachusetts 02161

- 1965 UNITRON Scientific, Inc., 66 Needham Street, Newton Highlands, Massachusetts 02161

- 1970 UNITRON Instrument Company, Telescope Sales Division, 66 Needham Street, Newton Highlands, Massachusetts 02161

- 1975 UNITRON, 66 Needham Street, Newton Highlands, Massachusetts 02161

- 1981 UNITRON Instruments, Inc., 175 Express Street, Plainview, NY 11803 (then a subsidiary of Ehrenreich Photo Optical Industries, Inc.)

- 198? UNITRON Instruments, Inc., 101 Crossways Park, West Woodbury, NY 11797 (still a subsidiary of Ehrenreich Photo Optical Industries, Inc.)

- 1992 UNITRON Inc., 170 Wilbur Place, PO Box 469, Bohemia, NY 11716

Later production telescopes sold in the USA may be accompanied by literature indicating the seller was "Unitron Instrument Company - Microscope Sales Division". This lack of continuity could not have helped the viability of the telescope product line in the USA.

It will be fascinating to observe the planets, moon and brighter deep sky objects through these telescopes and be awed, just as our predecessors were.

These rightfully have earned our admiration and their place on exhibit for all to see at Company Seven.

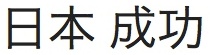

A Brief History and Marketing Primer: these telescopes and their accessories too were manufactured by Nihon Seiko Kenkyusho, Ltd. based in Tokyo, and by its subcontracted vendors in Japan. The company was established at least as far back as the the mid 1930’s, then furnishing fine achromatic refracting telescopes, based on the Carl Zeiss type E air-spaced doublet achromat lens design, of at least up to 125mm aperture under the POLAREX or SEIKO SCOPE trade names. By 1951 the company had emerged from the ashes of the war and offered their initial assortment of what was to become an extraordinarily well integrated and comprehensively accessorized line of telescopes and mounts.

A Brief History and Marketing Primer: these telescopes and their accessories too were manufactured by Nihon Seiko Kenkyusho, Ltd. based in Tokyo, and by its subcontracted vendors in Japan. The company was established at least as far back as the the mid 1930’s, then furnishing fine achromatic refracting telescopes, based on the Carl Zeiss type E air-spaced doublet achromat lens design, of at least up to 125mm aperture under the POLAREX or SEIKO SCOPE trade names. By 1951 the company had emerged from the ashes of the war and offered their initial assortment of what was to become an extraordinarily well integrated and comprehensively accessorized line of telescopes and mounts.

Above Right: Nihon Seiko in Japanese Kanji script. The first two characters translate to Nihon meaning Japan, and the other Seiko for success (54,097 bytes).

In the Fall of 1951 the United Trading Company (hence UNITRON) based in Massachusetts commenced marketing the telescopes in the USA. For most other countries they were marketed under the trade marks POLAREX or POLAREX, though some distributors also marketed them as UNITRON. We explain more about marketing and trade names at our Unitron Notes & Interesting Articles Index page. Their refracting telescopes were initially geared for the amateur astronomer and school science class markets, though the larger telescopes in particular attracted customers in higher education too. The Nihon Seiko telescopes were actively marketed until the discontinuation of routine telescope production in 1992.

Nihon Seiko marketed most of their transportable telescopes in two basic configurations: either with an Alt-azimuth Mount and wood tripod suitable for terrestrial and visual astronomy use, or with a German Equatorial Mount with wood tripod or metal pier that is better suited for astronomy uses. In terms of optical performance, mechanical quality, and comparative comprehensiveness of the system, these were among the better production telescopes sold from the 1950’s to the early 1970’s. As Unitron and Polarex distributors prospered, their offerings grew from the initial smaller models including the 2.4 inch telescope up to 6 inch observatory telescopes sold from the mid 1950’s. The largest ever produced was the massive 9 inch (225mm or 8.8 inch) made for permanent observatory installation.

Unitron evolved to offer microscopes and other scientific instruments, some that shared accessories or parts of accessories made for use with the astronomical telescopes. These instruments provide good performance in their day, beautiful appearance - they looked good just standing there, and were versatile given their well integrated system of accessories. While our community was saddened by the demise of the telescopes production, the Unitron company in the USA continues to distribute microscopes and other equipment. There are other companies bearing the Unitron name, including one distributing hearing aids, but these are not related to the Unitron that sold telescopes.

Marketing, Configurations, and History of the 4 inch models

The 4 inch telescopes were first introduced in the USA in the Spring of 1953. These were marketed in the USA and most English-speaking countries as 4 inch because the diameter of the objective (front facing) lens is the primary property characterizing a telescope. Even though marketed as a 4 inch, their lens cells and focusers are usually engraved D102mm and it is by their metric measurement that they were marketed in several countries overseas.

The 4 inch telescopes were first made available in the Alt-Azimuth (up-down and left-right moving) mount configuration and with the De-Luxe Focuser that was designated Model 150. In the following month the Model 152 was introduced featuring the 4 inch diameter achromatic refractor telescope supported by the German Equatorial Mount (in Germany this termed a “parallaktische Montierung”), this supported by a transportable wood Field Tripod and this set priced at $785. The Model 152 announcement also mentioned a photo equatorial version selling for $890, this was basically the Model 152 but furnished with accessories to facilitate guided astrophotography. These telescopes and mounts sets are heavy and too awkward for most people to carry for any distance. So one would transport the major components in their wood cases, then assemble the telescope in the field. Alternatively one could employ a wheeled dolly to facilitate rolling the set in and out of a garage for example. It would not be unprecedented to see such a physically large telescope installed in an observatory setting. In the summer of 1954, Unitron USA announced they were developing a pier to support their German Equatorial Head, this instead of the field tripod. This photo-equatorial configuration would be provided with the similarly recently announced weight-driven mechanical clock drive and configured for a permanent observatory installations; this would be marketed as the Model 166.

Each of these telescopes were marketed as a packaged set including a standard complement of eyepieces and many other parts, certainly enough to keep the new owner unpacking and figuring-out what they are for some time.

The 4 inch telescope we feature here was marketed in Japan and in several other countries under the factory’s trade name, SEIKO SCOPE, as the Model 132 - 4 inch Equatorial Refractor. In most other countries this telescope was marketed under either of the trade marks UNITRON or POLAREX.

The 4 inch telescope we feature here was marketed in Japan and in several other countries under the factory’s trade name, SEIKO SCOPE, as the Model 132 - 4 inch Equatorial Refractor. In most other countries this telescope was marketed under either of the trade marks UNITRON or POLAREX.

Right: Unitron Model 132 - 4 inch Equatorial Refractor with Sun Projection Screen attached, as illustrated and described in a Seiko Scope catalog (81,896 bytes).

Click on image to see enlarged view (183,011 bytes).

The most notable attributes of the Model 132 telescope set are:

-

1. The optical tube is built around their 4 inch aperture (D102mm) 1,500mm focal length (f/15)* air-spaced doublet objective lens optical tube assembly. For comparison of what this brings to the observing session consider its smaller cousin, the 3 inch telescope that provides about 107 times the light gathering power of the unaided human eye; that is about 1.5x greater than that of the next smaller Unitron 2.4 inch telescope. The 4 inch provides about 1.8 times the light gathering power of the 3 inch telescope, and 2.8 times that of the 60mm; so even when observing the fainter deep sky objects within its reach the improvement in what is shown by the 4 inch compared with that in the next smaller telescopes are obvious. Of course with the larger aperture too there is a proportionate increase in resolution, the amount of details that can be seen under ideal conditions on the objects of study.

2. The Model 132 telescope is provided with a German Equatorial Mount and wood field tripod thus this is capable of tracking and expansion into astrophotography, and yet it remains a transportable telescope. The wood tripods provided with most 4 inch telescopes incorporate three wood legs that each consist of two straight long sections joined together. This late production telescope features articulated legs that can fold approximately in half for more compact stowage than the standard legs sold for most 4 inch models, similar to the arrangement of smaller Unitron telescopes.

3. The set was provided with an assortment of seven eyepieces, and with an Achromatic Amplifier (Barlow Lens), 10x 40mm Finderscope, Sunglass (thread-in solar filter) with aperture diaphragm, Sun Projection Screen. Three wood cases rounded out the set to accommodate the OTA, another for the Mount Head, and the third for the Field Tripod Legs.

The German Equatorial Mount provides:

The Model 132, or Model 152, or Model 4732 Telescope?

Some readers acquainted with Unitron telescopes may be wondering why we refer to this telescope as a Model 132 or Model 4732, and not as a Model 152? This is because somebody in charge, probably at Nihon Seiko, failed to demand the standardization of model and part numbers among their world-wide distributors. So a telescope sold in Japan as the Model XXX was being marketed in the USA as something else (or not at all), or in Germany under yet another part or model designation. Frankly, even if Nihon Seiko had demanded standardization, then their own model numbering system would not have been our choice as it does not make as much sense as that of Unitron USA for example.

Some readers acquainted with Unitron telescopes may be wondering why we refer to this telescope as a Model 132 or Model 4732, and not as a Model 152? This is because somebody in charge, probably at Nihon Seiko, failed to demand the standardization of model and part numbers among their world-wide distributors. So a telescope sold in Japan as the Model XXX was being marketed in the USA as something else (or not at all), or in Germany under yet another part or model designation. Frankly, even if Nihon Seiko had demanded standardization, then their own model numbering system would not have been our choice as it does not make as much sense as that of Unitron USA for example.

The Model 132 is at first glance identical to the Model 152, even down to the provided German mount and accessories. What distinguishes the Model 132 sold in several countries overseas from the Model 152 that was marketed in the USA and in some other countries too, is the difference of focusers. The Unitron 4 inch telescopes were first introduced in April 1953 provided on the Alt-Az mount, these were marketed overseas as the Model 134 or in the USA as the Model 150; these are similarly equipped and incorporate the De-Luxe Focuser. The earliest advertising image of May 1953 show the then newly announced 4” Equatorial Refractor telescope with the De-Luxe Focuser. Soon after this the telescope was marketed in the USA as the Model 152, and this included the larger diameter Super Focuser as standard equipment. Both focusers incorporate a manually operated locking clamp so that the user can secure the drawtube at any extended distance; this feature can prevent the weight of an attached payload from inadvertently shifting focus while observing or taking astrophotos.

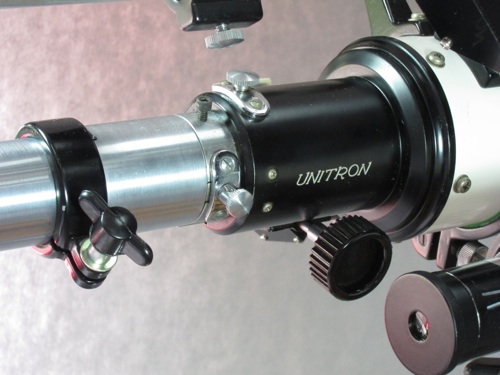

Left: A profile of perfect proportions! Our Nihon Seiko (Unitron) Model 132 - 4 inch Equatorial Refractor, note the standard De-Luxe model focuser (33,923 bytes).

Eventually the name became well enough recognized internationally that by the early 1970’s telescopes bearing UNITRON were being sold even in Japan. We know one person who purchased a new UNITRON 4 inch Equatorial Refractor in Japan in about 1973 and returned with it to the USA. For some forty years he thought that he owned a Model 152, but after reading this article he double-checked his original paperwork and realized his was in fact the version marketed overseas as the Model 132.

Just to add to your confusion, the example Model 132 4 inch Equatorial Refractor featured in this article was most likely sold new by the Unitron distributor in Germany. That distributor marketed this telescopes as their Model 4732.

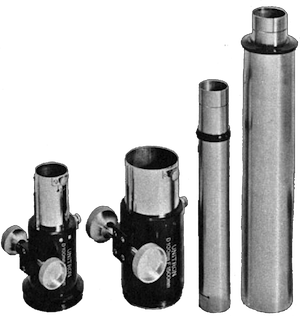

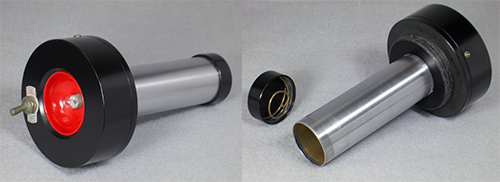

Focusers: the De-Luxe was the standard focuser provided not only on the Model 132 4 inch Equatorial telescope but also with the Model 134, the Nihon Seiko 4 inch Alt-Azimuth mounted telescope. While in the USA and in some other countries too these Alt-Azimuth telescopes were marketed as the Model 150 furnished with the Super Focuser, as were their USA equatorial mount versions. Either focuser is a rack and pinion arrangement that can accommodate the then common visual and photographic accessories that mate to either 0.965 inch or 1.25 inch diameter fittings, while the Super Focuser can accept those as well as the larger 2 inch diameter eyepieces and other visual and photographic attachments.

Focusers: the De-Luxe was the standard focuser provided not only on the Model 132 4 inch Equatorial telescope but also with the Model 134, the Nihon Seiko 4 inch Alt-Azimuth mounted telescope. While in the USA and in some other countries too these Alt-Azimuth telescopes were marketed as the Model 150 furnished with the Super Focuser, as were their USA equatorial mount versions. Either focuser is a rack and pinion arrangement that can accommodate the then common visual and photographic accessories that mate to either 0.965 inch or 1.25 inch diameter fittings, while the Super Focuser can accept those as well as the larger 2 inch diameter eyepieces and other visual and photographic attachments.

Right: Unitron trademarked De-Luxe Focuser at left alongside the larger Super Focuser, shown with their Drawtubes to the right (119,021 bytes).

Any of the 4 inch telescopes that would normally have been fitted with the De-Luxe Focuser could have been specially ordered, at some additional cost, with the optional Super Focuser. Either focuser could be purchased separately for the other smaller Unitron telescopes or by telescope-making amateurs for their own project, so a De-Luxe Focuser could have been upgraded later by the customer by ordering the Super Focuser. There are simple to change out since they thread-on and off of the telescope rear cell.

It would have been possible to acquire an Alt-azimuth mounted 4 inch telescope with the De-Luxe Focuser then adapt if for use with the German Mount, that would appear to have been a Model 132 sold overseas. It would have even been a simple matter to unscrew the Focuser assembly of the Model 132 and thread-on the Super Focuser, this would appear to be a Model 152 telescope. But it would have made no practical sense for a user to remove the Super Focuser provided with a 4 inch telescope and downsize that to the De-Luxe model.

Optical Tubes: the Unitron telescope optical tube assemblies are constructed from rolled and welded aluminum tubes, primed then painted gloss white on the exterior and antireflection flat black on the interior. In the case of the 4 inch models these incorporate a rolled tube of 4-3⁄8 inch outer diameter. The telescope optical tube accepts a spring-loaded lens cell at the front that is bolted on. Another metal cell, termed the Heavy Coupling in sales literature, is bolted onto at the rear of the optical tube. The heavy coupling provides added weight to help counterbalance the weight of the glass lenses and cell at the opposite end of the optical tube. The coupling is then equipped with either a thread-on Unitron De-Luxe Focuser or the larger Super Focuser.

With such a long focal ratio of f/15 these are lengthy telescopes, imparting more than their fair share of torque on a mount. Therefore, rigidity of the platform was a vital concern of the designers. When cased, then health and strength of the owner too are prerequisites to manage the nearly five foot (147 cm) long cased optical tube and the 51 lbs. (23.2 kg) weight of the cased mount head. Note, we at Company Seven consider these to be transportable telescopes and not pick up and go instruments.

The 4 inch Equatorial Telescopes Accessories: even by August 1954 there was a rapidly increasing assortment of goodies that one could add to their Unitron 4 inch equatorial telescopes. Some accessories under development then would never make it to market or would be renamed prior to being marketed; one product name most notably absent was the “super-secret UNIZOR” hinted at in their June 1955 advertising for example. By 1956 their catalog showed the telescopes and most of the accessories that would be the basis of the product line until its demise in 1992.

Nihon Seiko offered several basic versions of the 4 inch telescope with their German Mount. Some were marketed as the 4 inch Equatorial Refractor set up for visual work though these could be easily adapted to photograph the Moon, planets, and Sun. Other versions of the 4 inch telescope with their German Mount were furnished accessorized for astrophotography, these were marketed as the 4 inch Photo-Equatorial Refractor. Either 4 inch equatorial telescope was provided with at least the same basic accessories as our Model 132 including: auxiliary 10x 42mm Finderscope, a 0.965 inch diameter Star Diagonal (in some countries termed a Zenith Prism) 90-degree angled prism. The Star Diagonal makes it more comfortable for the observer to reach the eyepiece when the telescope is pointed to objects overhead. The image coming out of the rear of a refracting telescope would appear upside-down and backwards left to right, the Star Diagonal flips the image so that the object of study appears properly erect yet still backwards left to right; this is not as much a concern as comfort when observing planets or deep-sky objects. But Nihon Seiko ask includes a 0.965 inch diameter in-line observing image erecting Porro Prism that allows observing objects in their natural orientation too. These telescopes also included a cased assortment of seven or eight eyepieces, a Barlow doublet negative lens, a neutral density Moon Filter. Each telescope also included what Unitron termed the Sunglass, a light attenuating dark glass filter intended for use with the Aperture Stop though really not a safe filter for solar observing since it does not block infrared; this NOT recommended for use by Company Seven). The latter two filters slipped over the eyepiece and was held in place by tension of the thumbscrew. The eyepieces and filters were furnished in a fitted hinged-lid wood case, this set fit in a slot within the optical tube assembly wood case. Other accessories a battery-powered lamp that threaded into the base of the German Mount Head.

The equatorial models were also furnished with a Sun Projection Screen consisting of 1. perforated black anodized metal shade, and a 2. white-painted metal plate with both kept in-line by a 3. bracket-mounted support bar attached to the rear of the optical tube of the telescope, 4. Solar Diaphragm (Aperture Stop). The Aperture Stop restricts the opening at the front of the telescope and this prevents the full energy of the Sun, that would otherwise be focused by the objective lens into an intense beam, from heating and damaging the eyepiece. When employed with the aperture stop at the front of the telescope, the telescope projects an image of the Sun through an eyepiece attached to the the focuser, and onto the white plate. The perforated black shade casts a shadow on the white card except at the center onto where the Sun’s image is projected. This is a safe technique to observe sun spots or a solar eclipse.

The major components were shipped in wood storage cases, one for each of the major components and smaller cases for some of the accessories sets foo.

The Photo-Equatorial telescopes included other components to facilitate film astrophotography including: a 60mm (2.4 inch) x 700mm focal length photo guide telescope attached in parallel alongside the main 4 inch telescope. Since any 4 inch telescope configured for astrophotography was likely to accommodate heavier payloads, and since this was a more upscale model likely to be employing 2 inch eyepieces with a UNIHEX, then these were provided the upgrade Super Focuser and to help balance changing payloads at the rear of the main telescope a counterweight system is also provided, attached and parallel to the main telescope.

Those versions of the 4 inch telescopes that were initially marketed in the USA and in several countries overseas as the 4” Photo-Equatorial Refractor telescope were soon after designated the Model 155. Those sold in the USA and in some other countries as the Model 160 were similar but were equipped with the mechanical weight-driven clock drive. Those telescopes marketed overseas as the Model 132E 4 inch Photo-Equatorial included the Wood Field Tripod and were at a glance identical to the Model 160 sold in the USA as these were similarly equipped with the Super Focuser. But the Model 132E included the customer’s (or distributor’s) choice of either electronic Synchronous Motor or mechanical Clock Drive. The pier-mounted version of the set were marketed overseas as the Model 132F 4 inch Photo-Equatorial, while the pier-mounted version of the Model 160 was marketed in the USA and in some other countries too as the Model 166.

One cannot necessarily bank on knowing a used telescope was sold with this or that accessory since over time the original distributors may have scavenged or exchanged components, this was more likely to have occurred near the end of production at Nihon Seiko. Former owners too may have upgraded or changed out components. So a telescope originally sold as the Model 132 overseas might show up there or in the USA appearing as a fully accessorized Model 160 4 inch Photo-Equatorial Refractor years later. This is the case of our Unitron Model 142/145 telescope, that was originally purchased new then upgraded by the original owner over time to be equipped well beyond the Model 145 3 inch Photo-Equatorial Refractor.

Ours is among the later production examples featuring a fully multicoated air-spaced doublet objective lens labeled D102mm F1500mm (diameter and focal length), this was sourced from a well regarded maker in Japan. The telescope was acquired by Company Seven from a collector in Belgium, he had acquired this in Germany some years before. Since this is telescope has an original De-Luxe Focuser, and since the Unitron 4 inch equatorials sold in the USA (as the Model 152) incorporated the larger Super Focuser, and since elsewhere these were usually sold bearing the Polarex markings we suspect this Model 132 was originally sold through the Unitron distributor in Germany. The telescope was most likely sold no later than 1984, but not much earlier than that since the objective lens of older examples tend to incorporate violet-tinted magnesium fluoride antireflection coatings. In Germany these telescopes were marketed from the early 1960’s through the Spring of 1985 as UNITRON by Manfred Wachter Präzisionsmechanik und Optik of Bodelshausen at Tübingen (near Stuttgart), whose well illustrated literature remains a good source of information about these products even today.

This Unitron Model 132 telescope in our exhibit is unusually intact, and presents well. The 4 inch achromatic optical tube assembly shows few signs of having been used. The optics of this telescope and of all the mechanical components are original, intact, and functioning well. The greased components function acceptably well, but could nonetheless benefit from cleaning and regreasing before the telescope were put back into service. For static exhibit we find no need to disassemble the gears and bearings to perform that service.

The mount and tripod set has only modest signs of normal and careful use. The optical tube shows no signs of use or of aging. One small area of the Dew Shield does have some minor nicks on the that can be remedied with proper matching of the white paint. However, our priorities are to arrest decay and remedy where indicated, to replace missing or repair damaged components with original period parts, and to conserve for perpetuity. So we are rarely concerned about minor cosmetic issues. This telescope for example is missing the original Unitron Lens Cover that fits over the Lens Shade, so we will be on the lookout for that. In our efforts to restore the tripod for example we not only treated the wood to restore some of its former glory and preserve it better. We replaced one broken plastic knob capped wing nut, and another that was incorrect for this set. Fortunately there are many of these telescopes and their components in various states of repair for sale around the world, and so it is usually a matter of time and luck to find original replacement parts.

Upon first inspection of the 4 inch objective lens we observed there were some particles in the narrow air-space between the crown and flint lens elements. There was some spotting, a possible precursor of fungus, between the lenses (R2, R3) and on the rear element back surface (R4). The Newton Rings appeared decentered. To solve these issues required careful disassembly, professional cleaning and treatment, and reassembly. Throughout the process there must be a disciplined and proper technique; we will not explain how to do this work here because we do not recommend tampering with or disassembly of these lenses by those who are not trained in the work. Fortunately, we were able to restore both elements of the objective to an as-new appearance. After cleaning and reinstallation into the cell the lenses are clear. Our alignment process resulted in even better performance than when the telescopes were first evaluated at Company Seven, now showing the clearly defined and concentric Newton’s Rings interference pattern.

We have observed some advertised specifications for the objective lens these 4 inch telescopes call for a 102mm (4.02”) or even a larger 105mm aperture. Their lens cells and focusers are engraved D102mm or 105mm (4.13”) aperture objective. We measured the actual clear aperture of our Model 132 as 99.80mm (3.93”), that amounts to a 4.6 percent difference in light-gathering power yet we see nothing sinister about the discrepancy, it just offends our sensibilities - maybe our obsession with fact. In our decades of experience working with manufacturers and with distributors of telescopes, one not always being the other, we observed numerous instances where the people who write the marketing literature are not fully acquainted with the product. Because of this, some of the discrepancies between what is advertised and what is delivered originate simply from a misunderstanding. Or, the advertised specification may refer to an effort by the writer to simplify; 4 inch is easier to convey than 3.9 inch for example. If the clear aperture of the lens is 99.80mm while the overall diameter of the lens set unmounted from the cell is closer to 102mm (by our measure) then here too we can understand someone interpreting the focuser should be labeled 102mm and the marketing could reflect that too.

Some of the components bear stick-on labels that indicate they were made in Japan. Unfortunately there are rarely any serial production numbers on these telescopes optical tubes or mounts. While there may be a number related to production by a subcontractor on a lens set for example, we have not found any markings on the lens or cells of those Unitron telescopes in our exhibits to give any hint about their distributor or original market region, or date of production.

Regardless, if our particular telescope is not well documented then we can imply a production date range based on some of its features. So we may deduce or speculate about the issue of when it was made, even if we can not say for sure when it was sold. Even if some of the accessories or even the objective lens date to between about 1982 to late 1984, we must consider it is possible that accessory could have been previously interchanged with one from other telescopes, or replaced years after the telescope was originally sold.

Right: Unitron cased accessories including standard eyepieces and filters, and with the optional 4mm eyepiece for our Model 132 telescope (60,039>.

The fact that some eyepieces bear the name Unitron or Polarex or none at all is not unusual especially later in production because Nihon Seiko was scrambling to fill orders for distributors from dwindling production and a diminishing pool of inventory. Furthermore, it is not uncommon for owners to have lost or traded and later replaced or acquired eyepieces with whatever labeling or not became available.

The cased accessories set is complete, with all the pieces and parts mentioned earlier in this article. The eyepieces and filters are stored in their fitted hinged-lid wood accessory case, that fits in a storage slot within the optical tube assembly wood case. The wood case of the optical tube assembly has spaces to accommodate the provided Star Diagonal and Porro Prism. Furnishing a Porro Prism for such a long focal length telescope and for one sold on a German Mount strikes us an anachronism, unless someone observing the Moon might prefer the correct orientation. These are all shown in the photo at right, housed in the eyepiece case.

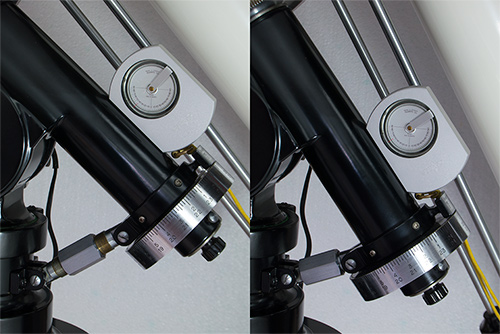

The mount head is furnished with a latitude adjustment mechanism, this allows fine adjustment of the tilt of the mount head when Pole Aligning. The range of latitude where the mount can be aligned, on a level surface, spans from 55 degrees down to about 42 degrees where only one thread remains securing the coupling. When nearing the operating limits of the lower latitudes then only one or two threads are supporting the load, and so it would be critical to lock the main bolt at either side of the mount head.

The wood Field Tripod is uncommon in that the legs can be folded into a more compact form for transport. There is some flaking of the black paint on the wood tripod metal leg tips, but this seems to be the norm as the tips of many Unitron tripods were not well primed before painting.

The hinged solid wood telescope and mount cases arrived in good condition, with no damage to the support braces inside as is often seen in other examples; this is a testament to both the packaging skills of Mr. Debeerst and the handling care of Federal Express. The cases needed only some cleaning and conditioning before being added to the exhibit. Since our general policy is to conserve antiques - to clean and protect them from decay, we display this telescope among our exhibits at our showroom cleaned and assembled but otherwise as it arrived.

Unitron Equatorial Refractor telescopes were sold new equipped with several eyepieces and choices of interesting accessories such as the UNIHEX or a Star Diagonal; ome of these accessories would be optional for telescopes sold overseas including our own Model 132. The UNIHEX as the term for the accessory permits the user to store as many as six eyepieces at the rear of the telescope, dialing in one eyepiece after another thus varying the magnification quickly at will. In other countries what was marketed in the USA as UNIHEX bore other names, in Germany for example this was the Okularrevolver. Of course the 4 inch telescopes could be outfitted with the UNIHEX, and because most 4 inch Unitron telescopes sold in the USA and some other countries too were equipped with the larger Super Focuser and could accept 2 inch eyepieces a larger version of the UNIXEX was marketed in some countries to accept up to one 2 inch eyepieces and five smaller eyepieces too. The DEUTRON is another interesting, accessory that allows one or two observers to simultaneously observe the same object through the telescope. For astrophotography there is are optional photo-guide telescopes, optical tube counterweight set, even the ASTRO-CAMERA 220 too. Many of these accessories were provided in their own fitted wood boxes. Some of the accessories that are exhibited on our Model 132 telescope are described here:

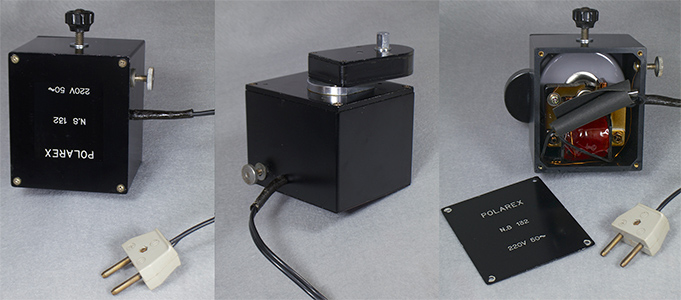

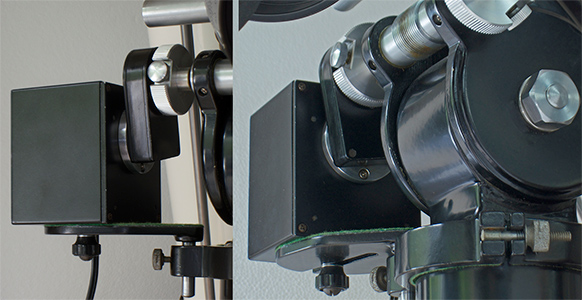

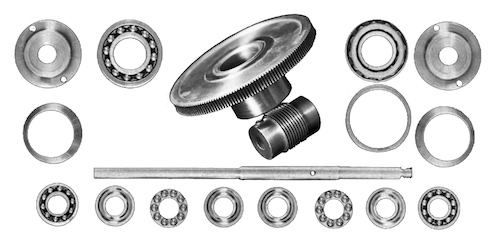

Mechanical Weight-Driven Or Electric Synchronous Clock Drives: as the Unitron telescopes entered the market in the early 1950’s, a drive system to automate tracking along the Right Ascension (R.A.) axis of the German Equatorial Mount was not provided as standard equipment but was optional. The drive motor and gear reduction set would couple to and automatically turn the Right Ascension Worm Gear of the 4 inch Equatorial Mount at the rate of one revolution every 484 seconds (8.0667 minutes) to maintain tracking at the Sidereal Rate. Incidentally, the rate for the smaller 3 inch Equatorial Mount motor was slightly slower, and that of the 2.4 inch Equatorial was notably slower and so motors could not be interchanged even though they shared the same 9mm diameter hex drive shaft.

The mechanical Clock Drive, a weight-driven system, was announced as under development in the Summer of 1954. The Clock Drive is so termed because the the drive movements of first tracking telescopes were based on a conventional 12 hour clock movement but made to rotate once every twenty-four hours or once every 23 hours and 56 minutes at the Sidereal Rate. The mechanical Clock Drive features a speed control so the user can vary the rate to compensate for temperature change effects of the mechanism, or to change the rate for Solar (slower) or Lunar (faster) studies. This is not as responsive or precise, especially as the mechanism ages and wears, as an electronic motor-driven system or the later frequency regulated (Quartz, etc.) systems. An overseas Model 132 telescope sold new with the Clock Drive was marketed as the Model 132F. In the USA the Model 152, also sold without motor, was marketed as the Model 155 with this mechanical Clock Drive. The weight-driven Clock Drive continued to be offered as an option, selling in the USA for $605.00 near the end of production in the mid to late 1980’s.

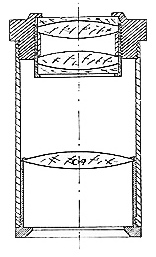

Right: views of the Polarex labeled Model 132M synchronous 220v 50 cycle AC motor for our German Mount. The motor is shown here on a flat side but that is upside down, when installed the Motor Tray attachment bolt is at the bottom. At center note the swiveling gearbox assembly atop the motor. At far right the interior showing the transformer and motor (97,057 bytes).

Most telescope Drive Correctors of the period permitted the user to make fine adjustments to the tracking speed by dialing to a Sidereal, or Solar and or Lunar rate. The more sophisticated Drive Correctors included a hand held controller that made it easy for the user to make momentary corrections of Right Ascension (and Declination if the telescope mount had that second axis drive) that might be necessitated by the worm gear error or by slight Pole Alignment errors. Lacking a drive corrector the Declination control movements would have been performed by finely turning the manual Declination Control flexible cable.

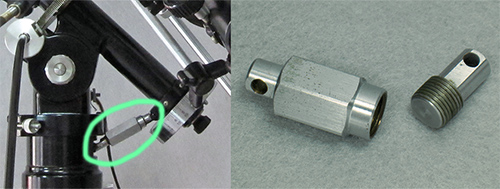

Left: a Model 132M synchronous motor attached to the R.A. Gear Coupling (note the thumbscrew). The views show the R.A. Main Gear, Motor and Gearbox, Motor Support Tray, and Motor Tray Ring (101,120 bytes).

Selecting the correct motor meant specifying the mount, so this would be a Model 131M for 3 inch telescope mounts or the Model 132M for 4 inch mounts*. The correct mains voltage and frequency/cycles in Hertz for the region, this would be labeled 100v 50

There are 12 volt DC to AC power inverters available that would permit operating the motor from a portable battery pack. However, it would be vital to insure the inverter provides the correct frequency. So for example, a simple 12 volt to 220 volt AC 60 cycle inverter would play havoc on the tracking rate of our Model 132M 220 volt 50 Hz motor. To learn more about how these motorized telescopes may have been operated and controlled in the field, study the Model 142 telescope in our exhibit that includes the Unitron 115 volt 60 cycle AC Synchronous Clock Drive and with a Gieseler Electronics AccuTrack Model 2117B Single Axis Drive Corrector, that provides square wave AC power to the Right Ascension motor. Gieseler Electronics, founded by Time Gieseler went on to sell third party telescopes too and in time branched out into the selling of imported telescopes bearing the Orion Telescopes brand.

Right: Unitron telescope tripod shelf illuminator, front and with the rear open to show battery compartment (46,055 bytes).

This consists of a spring-loaded compartment holding two conventional flashlight batteries that threads onto a machined housing, the housing incorporates a flashlight light bulb with a red reflector this controlled by an on-off toggle switch. The miniature lamp is a common 2.5v 0.3A Edison E10 (10mm) base screw with CR2 filament: GE G11 or 14AC/DELCO. The assembly should thread into the bottom of the center casting that joins the three tripod legs to the 4 inch mount head. When switched on the lamp illuminates the accessory tray below.

Left: Unitron shelf illuminator bulb, shown alongside Lincoln Penny for comparison (41,443 bytes).

We underlined the word should because in theory the assembly threads into the base of the mount. We have observed many minor changes of dimensions and thread pitch over the forty years of production, and so finding a shelf illuminator is one thing but getting it to thread into your mount may be another matter. This brings up the issue of variations of specifications of production over the years. Our late production Model 132 mount has threads 60.0mm in diameter, while the threads of the illuminator measure 62.5mm and so these are incompatible. Nonetheless, the illuminator looks good in the photos here and on static display too.

This is a relatively obscure item that is rarely found in good condition today. We suspect this is because the then popular general purpose zinc-carbon dry cell batteries of that era were notorious for leaking (sooner or later) and corroding the device hence it was likely discarded. For this reason, those used illuminators that have survived likely did so because the user was in the habit of removing the batteries from the device when it was not being used for any extended period of time. By the 1970’s there were more handy compact flashlights coming onto the market, and so the need for this fixed accessory declined. Many of these portable lights provided the lamp could be filtered red to suit the users preference, and so these could do double duty for regular use around the house or filtered dim red for reading charts and guides alongside the telescope. Of course, the original owner may have been misplaced the item, or a new owner may not have understood the purpose of the illuminator or where the illuminator is to be installed. So, it appears that many of these were lost or discarded.

When employed in moist or high dew environments then over time the light bulb or socket, even the on-off toggle switch too could corrode and fail to illuminate so it it likely that a number of these simply fell into disrepair and were discarded. Fortunately for our exhibit, our Shelf Illuminator arrived apparently unused and in its original packing. Even still the visible metal parts of the Shelf Illuminator switch, the bulb screw thread, and the spring in the battery comport too signs of minor surface oxidation.

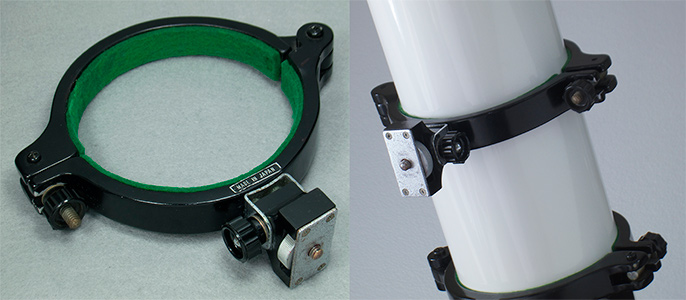

Right: UNICLAMP ring at left, and shown at right attached to our Model 132 4 inch refractor optical tube (83,575 bytes).

The UNICLAMP Camera Bracket should not be confused for the standard UNICLAMP. The UNICLAMP is a hinged ring designed solely to accept bolted on accessories, these were best sold by the pair to permit the fastening of accessories including Photo-Guide Telescope mounting rings for example

Stand by as we hope to add more and more optional goodies to our telescope set - and we will write about them too!

The telescopes marketed in the Americas under the trademark UNITRON were produced by Nihon Seiko Kenkyusho, Ltd. of Nozawa, Setagaya-ku, Tokyo, Japan. This company and its affiliates manufactured telescope and other scientific instruments. We have no substantial information about how Nihon Seiko Kenkyusho came to be, or when they developed their line of fine achromatic refracting telescopes. However, the company was established at least as far back as the the mid 1930’s, then furnishing fine achromatic telescopes of at least up to 125mm aperture to universities under the POLAREX and SEIKO SCOPE trademarks. By 1951 the company had emerged from the ashes of the war and offered an their first assortment of what was to become an extraordinarily well integrated and accessorized line of telescopes, mounts, and accessories.

Right: one of the first models offered by Unitron; a 2.4 inch Model 114 telescope of the Company Seven Museum Collection.

Japan had become the butt of 1950’s quality control jokes, “made in Japan” was generally not considered a compliment. But Japan’s industries improved, they became innovators, and the Japan of the late 1960’s into the 1980’s came to dominate the production of small moderate to excellent quality optics including telescopes, cameras and microscopes. Unitron appealed to the more demanding clientele, a limited portion of the marketplace. Nihon Seiko was not particularly innovative in that most of what they offered in the 1950’s had been developed and sold by other companied well before World War II. However, Nihon Seiko complied the most comprehensively accessorized lined of well-made telescopes if their day. Furthermore, Nihon Seiko allied itself with a series of exclusive overseas distributors who would actively promote the line so that by the late 1950’s almost everybody involved with astronomy in the USA for example had heard of Unitron, even if they could not afford one. Over the years Nihon Seiko were to stay loyal, one could argue unfortunately mired, to their offerings and principles.

The aspect of their history in the USA commenced when United Trading Company acquired the rights to distribute the Nihon Seiko telescopes and their accessories. United Trading was founded by Lawrence Fine with offices and a shop at 204 Milk Street, Boston 9, Massachusetts. Soon after going into business United became United Scientific Co. and developed an acronym under which the telescopes might be more readily recognized, the trade name UNITRON.

Simultaneously the telescopes continued to be marketed in western block nations of Europe and most Commonwealth nations (Australia, New Zealand, etc.) under the trade names UNITRON and or POLAREX. For example, in Japan and in some countries these sold under their trade name Seiko Scope; our 3 inch and 4 inch telescopes are among those listed in the Nihon Seiko catalog under the Seiko Scope Equatorial series. Some smaller quantity production lots of telescopes were made by Nihon Seiko Kenkyusho under other trade names including WELTBLICK (World View), but these are not anywhere near as common as those bearing UNITRON or POLAREX trade names.

Eventually the UNITRON became the most well-known of the trade names in no small measure owing to the proliferation of marketing advertisements in numerous astronomy publications by Unitron USA companies, and the prevalence of Americans visiting and residing for their work in many First World countries where there was interest in astronomy and the sciences and where these could be successfully marketed. The name became well enough recognized that by the early 1970’s telescopes bearing UNITRON were being sold even in Japan.

Given the limitations of the crown and flint glass available then, in order to provide good performance the better refractors made from the 19th through the mid 20th century are lengthy beasts. Typically their focal ratio, the ratio of lens diameter to their measure of basic image enlargement (or focal length), is on the order of f/15. Hence 4 inch aperture x 15 = 60 inches or about 1,520mm. So even our comparatively small Unitron Model 114, a 2.4 inch f/15 telescope, is challenging to work around with when housed within a six-foot diameter observatory dome as we exhibit it at Company Seven. Our 3 inch f/16 equatorial telescope stands so tall that it will just fit in a room of a typical home or apartment.

New accessories and minor adjustments continued as the telescope line got its legs in the marketplace. In May 1955 “UNIHEX” was announced as the name for Unitron's new six position rotary eyepiece holder; the competition to come up with the name was won by three amateur astronomers and each was awarded a UNIHEX. While each entrant in the competition was sent as a gift The Nature of the Universe, a book by Fred Hoyle published in 1950 that is based on his series of radio talks about astronomy presented on the BBC.

Adjustments to the line over the years included changes of designations and availability of some accessories. For example 2.4 inch models are usually referred to as 2.4 inch or occasionally as 60mm in the literature, but at least some of the telescopes of 1954-55 are engraved D 62mm F 900mm, by the mid 1950’s this would be changed and remain D 60mm F 900mm. Some earlier production telescopes may have no information about the telescope make or size on the lens front cell, only listing the basic UNITRON along with aperture and focal length on the focuser. In time the diameter, focal length, and UNITRON (or UNITRON) were painted onto the front cell in simple thin block lettering. But by the mid to late 1950’s the contemporary scheme of painting the front cell with this information, as is on our telescope, had become standard.

On our 1970’s production 3 inch telescope the provided objective lens covers slipped onto the front; these are embossed with UNITRON in lettering. The older telescopes might be a simple unmarked cover, or these could be a white painted cover with lettering in red (mid 1950’s). But in the late 1950’s Unitron settled into black with white painted lettering, this would be the norm through the late 1960s. Most were minor changes, but none that made one component or the other obsolete.

There was little in the way of true innovation with the telescopes or product evolution: the products available in 1972 were fundamentally the same as those shown in the 1956 catalog. At their inception Nihon Seiko accumulated wisdom from other accomplished makers then integrated these ideas into their production - and did so with class. What Nihon Seiko did manufacture was made after careful thought, with an above average degree of precision and uniformity, made of appropriate materials smartly engineered to work well and save weight. Each component was assembled by caring craftsmen who obviously took pride in their work. Nihon Seiko developed a well-integrated integrated system, for the time, and with a good selection of optional accessories. These accessories increased the versatility of the telescopes, while some of these items simply made it easier or more comfortable to use the telescope. These telescopes were produced in quantities large enough so that the economies of scale with then affordable Japanese labor allowed their prices to remain below that of the most highly regarded competing refractors (Zeiss, Goto, Tinsley, etc.). With numerous quality control steps throughout the process the factory insured every telescope made would be a garner admiration and confidence, as well as good performance for the new owner.

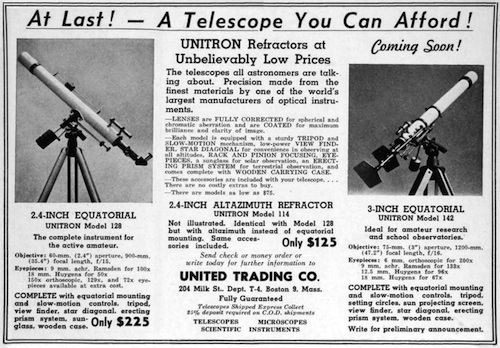

The first United advertisement in the Americas introduced their 1.6 and 2.4 inch aperture telescopes under the heading "At Last! - A Telescope You Can Afford!". This was submitted late in the Summer of 1951 for placement into the October issue of Sky and Telescope, soon after this was followed by ads in other issues and in Scientific American magazines too.

Right: April 1952 announcement in Sky and Telescope Unitron introducing the Model 142 (98,669 bytes).

A curious change between the two introductory advertisements and those subsequent ads that followed is that in the first two ads the Model 142 telescope is pointing to the right, while in following ads the same photo is reversed so that the telescope points to the left.

In time Unitron ads would appear in other publications too including Popular Mechanics and Science Digest too.

In 1952: the cost of this telescope set with two eyepieces and a standard diagonal (before the UNIHEX was available) was $125 plus shipping. This was a long time ago; President Harry S. Truman was still in office, the Korean War was still on. So to gain some understanding about the times and how the cost of this telescope compared to other typical expenses of 1952:

Interestingly enough, moreso for people of our times used to seeing prices escalate from year to year, the original selling prices of these telescope did not vary much between the 1950’s when they were introduced and 1970, yet consider the impact their costs would have had on a buyer. In 1952 the Model 114 telescope cost the average household nearly two weeks salary! If we refer to the U.S. Government Consumer Price Index Inflation Calculator (CPIIC) we see $125 in 1952 had about the same buying power as $1,115.40 in 2014, when this telescope arrived at Company Seven. Incidentally, the $585 of 1985 corresponds to $1,295.32 in 2014. So even their entry level telescopes were quite an investment for the average consumer.

Our Unitron Model 142 3 inch telescope we display is better accessorized than the basic Model 145 including accessories that were not sold in the mid 1950’s. The 4 inch Equatorial Refractor (Models 132 and 152) was announced in 1953.

In 1953 the Model 132 and Model 152 telescopes each cost the average household more than nine (9) weeks pre-tax salary!

Getting The Points Across: During the mid 1950’s the most noteworthy competitors of Unitron’s refracting telescopes were the Newtonian style reflecting telescopes and parts including those made by Cave Optical Company, Criterion Co., Edmund Scientific. So in 1955 Unitron unveiled a new part of its sales strategy that included humorous cartoons lampooning those bulky and heavier telescopes, and some competing refractors too. These are a few of those cartoons drawn for Unitron sales literature by the talented and acclaimed illustrator Ken Muse (b. 28 Apr. 1925, d. 19 Jun. 2010):

Above: cartoons drawn in 1955 for the Unitron catalog and other sales literature by illustrator Ken Muse (38,353 then 43,524 and 38,401 bytes).

The Model 166 4 inch, 5 inch and 6 inch pier-mounted photo-equatorial refractor telescopes had been in the product lineup since at least 1956; these had been the flagship models and appeared in catalog and in advertising media. By the late 1960’s plans were in the works to build even larger observatory based instruments, sold only on a special order basis, and the first of these was to be the 8 inch (200mm) model. Some of the advertising by Unitron USA in 1975 were among the last featuring the larger telescopes, Model 166 4 inch and 6 inch pier-mounted photo-equatorial refractors shown alongside each other, and with a woman standing alongside for comparison. However, we do not recall ever before seeing any similar advertisement or mentions in earlier Unitron or Polarex catalogs of their largest telescopes. Their largest model was developed in the late 1980’s and this was the 225mm (8.86 inch) f/14.7 refractor telescope also featuring a multi-coated lens, that would certainly have been a special ordered instrument.

Throughout production changes to the equipment were not arbitrarily made, and parts support remained excellent for some years beyond the formal demise of the telescopes distribution - this was good for those who choose to restore a Nihon Seiko telescope. It is not uncommon to find parts bearing various trade names on a used telescope since some years following the discontinuation of production their owners salvaged parts from various sources here and overseas. So for example one might find a POLAREX labeled 1980’s telescope with a 1950’s Seiko Scope labeled lens cover and with other parts labeled UNITRON.

Right: Objective Lens of our Unitron 4 inch Model 132 telescope. Note the aperture engraved reads 102mm. This lacks the red anti-tampering paint usually found on these cells (73,735 bytes). The same model lens may be found bearing the same basic lens specifications but with the Polarex trademark, these were for distributors outside the United States.

The two lens elements are kept apart at the nominal distance from one another by aluminum foil spacers. The three spacers are laid in at the edges and between the lenses, 120 degrees apart, and have no perceptible adverse impact on performance. The spacer is of the thickness determined by the lens design prescription, but when looking at a lens outside the cell then at first glance it is hard to see any air gap between the lenses. The lens elements and spacers are carefully slipped into a cylindrical lens cell and this is all held together by a retaining ring, the retaining ring is held in place by three bolts. The 4 inch and larger telescopes lens retaining rings features six adjustable push screws, these are adjusted to insure the cell is not threaded-on so tight that it compresses the objective lens. Such compression of a lens, or pinched optics, degrades the performance potential of the lens particularly when the lens and cell expand with temperature changes.

The entire lens cell slips onto the spring-loaded front cell of the optical tube, and is bolted into place and aligned (collimated) to the optical tube by means of the three surrounding flat head screws.

In photography too, in color or even in monochromatic (black and white) imaging sharpness is undermined, and bright stars will appear a bit bloated. This caused by the halo of secondary color that does not focus within the same area of the disc as does the red and green components.

Left: zoomed-in Digiscope of an Egret taken with a pocket camera. Before zooming in onto the Egret the image appeared well, but just lacking some snap. As the camera zoomed in then the image shows chromatism (violet false color) more and more obviously, especially pronounced where light and dark areas contrasts exist. The violet cast overall and the color fringing come from the lens of the pocket camera used to take the picture (124,684 bytes).

Regardless, chromatism was a common issue for most refracting telescopes and telephoto lenses manufactured into the 1970’s since the apochromatic refractive systems up to this time were costly and complicated to make - and even the best of the time could not equal what was to follow.

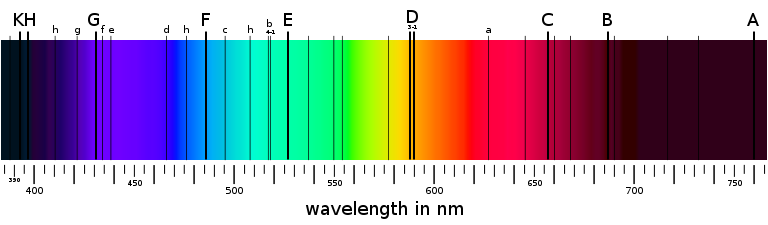

Above: Table above expresses optical properties including color correction in Nanometers at various Fraunhofer color lines (C to G).

For additional information about where the Fraunhofer lines correlate on the spectrum see below:

The Nihon Seiko lenses are so smoothly figured and polished to meet the nominal prescription that the final degree of spherical aberration of these Nihon Seiko achromatic lenses is quite good so visual images appear sharp and clear so any residual false color is not that problematic to the novice observer.

This is demonstrated when you look to the uncoated glass window pane of a door or of a display case for example, there is enough light reflected back at you so that you can recognize your own image and that of the surroundings. Furthermore, the cumulative effects of losses per surface can cause dramatic reductions in what can be observed of the fainter objects in particular.

AR Coatings Development: prior to 1935 all refractive lenses were made with no protective or anti-reflection treatments, the bare glass was exposed to the air or cemented to other lens components. The smoothly finished clean surface of a transparent material, glass or plastics, can reflect substantial incoming light. The light reflected depends on the properties of the material, the angle of the light source to that material (angle of incidence), and the angle of the observer to the surface, but this loss may be anywhere between four to about sixteen percent per surface. Consider what you see when you walk by a window pane? Your reflection. There is enough light reflected off that glass surface so that you can discern the image. The same thing was happening in telescopes, eyepieces, camera lenses - but worse. Since optical instruments and lenses consist of multiple elements of glass, there was the tendency not only to reflect light off the first lens surface but also to reflect light back and forth between uncoated air-spaced elements in the system. When multiple surfaces of glass are lined up, one behind the other such as in a telescope doublet or triplet lens or in an eyepiece, then these reflections tend to multiply as they reflect back and forth between each surface each slightly out of phase with the other to reduce contrast. This not only decreases contrast and overall light throughput, but reflections can cause a ghost’ or second image to appear. The observer would be likely to experience the effects of these issues when observing a star cluster for example where one or more faint stars may appear in the field where there would otherwise be none, or when observing a planet then the contrast and color saturation may be diminished. The result of treating a lens surface with an antireflection coating is to decrease flare and unwanted stray reflections, thereby reducing the potential of loss of contrast for an observed image.

Dr. Alexander Smakula (b. 9 Sep. 1900, d. 17 May 1983) led the team at the Carl Zeiss AG company at Jena that developed T-optic, the first anti-reflection coatings process devised for lenses. This was patented on 1 Nov. 1935 but kept a military secret throughout the following year. The first generations were a purplish tinted microns-thin layers of magnesium fluoride (MgF2) a metallic salt. When precisely applied in a vacuum chamber to the lens surface this reduces the amount of light reflecting off of a glass surface and thereby increases cumulative light throughput. These coating reduce undesirable reflections of light between glass elements thus increasing contrast and reducing the potential for ghost images. This was a noteworthy achievement in optics, and it kept Zeiss camera lenses and more sophisticated optics at the forefront of technology in the 1930’s. Initially only the more critical optics were treated, some of these are marked T for transparenz. Over time even optical lens components of devices intended for routine uses (eyeglasses, binoculars, etc.) were coated.

Antireflection Coatings Of Nihon Seiko: the pre-war Nihon Seiko amateur telescopes predate the development of the MgF2 coatings, so when looking into the lens one can see the whitish reflections clearly. During the course of production and spanning the the first thirty-five years or so after the war, Nihon Seiko specified every completed air spaced lens element was to be treated with Magnesium fluoride (MgF2) antireflection coating process, sometimes termed quarter-wave coating, to improve light throughput and to reduce the possibility of ghost images. The microns-thin single layer antireflection coating of magnesium fluoride coating presents with a purplish tint, this can be observed by careful inspection of telescope lenses as well as on their eyepieces too. Other components that incorporate refractive air spaced elements, including the finder, the glass prism inside the UNIHEX or DEUTRON and that in the Star Diagonal for example, will feature AR coatings. This is indicated in some of their advertising and in other factory literature by the mention of lenses fully coated. The objective lenses of the late production telescopes featured slightly improved multilayer antireflection coatings, usually presenting with a greenish tint. The long Dew Shield blocks out much of the stray light that can originate from the side (off-axis) of the objective lens, while the interior of the telescope optical tube and of each eyepiece barrel, and other in-line components are painted anti-reflection black.

The difference in transmission between the magnesium fluoride and the later multi-coating is not as significant as that between an uncoated and a single coated lens, though in more complicated lenses with many lenses in line (more complex eyepieces, etc.) then the benefits can be more apparent. The AR coatings subdue undesired reflections, otherwise it was possible to have one brighter star reflect back and forth between eyepiece elements thus giving the misleading appearance as though there were other stars in the field of view. The curves of these lenses are so subtle that ghosting could only rarely become a concern in practice.

The OTA Mechanical Aspects - This Is What A Refractor Should Look Like.

The optical tube assemblies of the Nihon Seiko telescopes, going back at least to the 1930’s, are fully constructed of rolled metal with cast focuser and front cells. The components have been painted in the traditional color schemes of black and white. Some very early examples with brass focusers for example may have left the factory in their natural finish. But the Nihon Seiko telescopes we usually see have a white painted optical tube with black painted front and rear cell, and focuser castings. The interior of the optical tube assembly from the inside of the slip-on Dew Shield, down the length of the baffled interior and focuser along with the provided extension tubes were painted with a flat black paint. This interior treatment contributes to the high contrast of these systems, systems where the background of space might appear as black as the blackest velour. The black dust cap (lens cover) slips onto the open Dew Shield, and this bears the UNITRON trademark in white on older models or has UNITRON molded into the front on later production models. Our 3 inch telescope and its 2.4 inch photo guide telescope covers have the embossed UNITRON.

The long focal ratio and precision machining of the optical tube and lens cell make it a fairly simple matter to assemble the mechanical components, install the lens, and have it be suitably collimated at the factory. Thus the smaller 60mm telescopes have no push pull lens cell or other means to adjust the lens alignment to the tube. The larger telescopes including our 3 and 4 inch models do feature a collimate able lens cell; this is also desirable because it facilitates removal of the objective lens for cleaning or transport and for precise installation.

The optical tubes of the early production small telescopes were bolted directly onto the mount saddle; this can be seen in the advertisement from 1952 shown above. These early production telescopes can be distinguished from later production (about 1955 and later) where the telescopes are attached onto the mount by means of detachable hinged mounting collar. Having mounting rings or a collar allows the user to loosen the collar enough to slide the OTA back and forth to compensate for changes of payload, this balances the instrument on the mount and results in smoother movement and less risk of damage if a clutch is accidentally loosened. The Unitron Model 142 in our collection employs the mounting collar.

Nihon Seiko sold telescope components to third parties too. One of the better known examples are the pale blue painted optical tube assemblies (OTA) sold by Don Yeier’s Brandon Company in the mid 1980’s. These 5 inch Brandon telescopes incorporate an f/8 standard Christen Triplet Apochromat objective lens (yes made by Astro-Physics Co.) mated to a shortened Nihon Seiko 5 inch telescope optical tube with the 2 inch focuser.

The Focuser: the De-Luxe Focuser was provided as standard equipment on the Model 132, or this could be purchased separately as an upgrade for other smaller Unitron telescopes or by telescope-making amateurs for their project.

The De-Luxe Focuser is built upon a body made of cast aluminum and with a diagonal-cut rack and pinion drawtube arrangement that is smooth when clean and provides 24.15mm of travel. Because of the limited focus travel the set included an 36.2mm (1.4 inch) diameter focusing sleeve, this is an extension section to be pulled out of the drawtube as needed. At the tip of the focusing sleeve is a friction sleeve into which 0.965 inch diameter eyepiece could be inserted. The friction sleeve could be replaced with one to accept 1.25 inch sleeve. Or the entire drawtube was removed to accept the UNIHEX with its own provided drawtube. The focuser body is painted black, and tastefully engraved with the engraving inlaid with white paint.

But to reach focus could be tedious since the focuser drawtube alone could not provide enough extension to accommodate as broad a range of accessories as were offered for these telescopes. So one needed to loosen the clamp at the end of the focuser drawtube (without letting the clamp fall off), then insert the appropriate focusing sleeve, then slide the focusing sleeve in or out of the drawtube and lock it in place (after you find the clamp that fell off) so that the accessory could then be attached and drawn in or out to reach focus by turning the pinion hand knob.

On the earlier production smaller telescopes, including our 2.4 inch Unitron, there is no drawtube lock provided. There is no way to quickly adjust the tension on the drawtube or the amount of effort needed to turn the pinion control knob. Most of these telescopes sold for astronomy were shipped with the smallest model of the UNIHEX, and this accessory alone adds some 3/4 lbs. (334 g) of pull on the drawtube, adding the eyepieces adds somewhat more. So one needs to rely on having the focuser pinion tension set so that it does not allow the drawtube to slide back (drawing the image out of focus) when pulled upon by heavy loads. The De-Luxe focuser incorporates a provision for locking the focus at any setting; a must for astrophotography, particularly when used with a heavy camera attached. The lack of a drawtube lock can be a deal breaker for anyone seeking to buy a smaller Unitron for astrophotography, so look for a focuser that incorporate the focus lock. Interestingly too, many of the smaller optical tubes packaged as photoguide telescopes lack any drawtube locking mechanism.

The focus control knobs of these telescopes were originally precision machined out of aluminum alloy, then anodized into a natural metal finish. However, between 1959 and 1961 Nihon Seiko transitioned their telescopes models over to attractive yet still durable black plastic knobs.

In the 1950’s it became common to hear the term “Made In Japan” being associated in a derogatory way with products exported from Japan since many items originating from there early after the war were poorly made or inconsistent. In an effort to promote and improve Japanese made products for export the government established trade groups to police manufacturers of goods for export; those manufacturers who complied with the quality and consistency requirements of the association could have their products bear an approval certificate or sticker. There were optical police too, so the better telescope manufacturers of Japan were affiliated with the Telescope Inspection Institute, hence the focuser of most telescopes made from the 1960’s into the early 1980’s may bear a sticker reading either “JTII̶a; or “Passed, Japan Telescope Inspection Institute”. The latter is the sticker affixed to the original focuser of our telescope too.

Above Right: De-Luxe Focuser, ordered by the original owner and installed by him onto our Model 142 telescope, shown with drawtube extended and with the extension installed.

One final observation; when a customer ordered an upgrade focuser from Unitron then it was not always guaranteed that the focuser body would have the telescope information engraved. The original owner of this Model 142 ordered the upgrade focuser and received one with no telescope OTA information, hence unlike the original focuser shown above right that is labeled "D 75mm F 1200mm", while the De-Luxe focuser is only engraved with the UNITRON name.