Distribution

![]() Zeiss Index

Zeiss Index ![]()

![]() News

News ![]() Notes & Interesting Articles

Notes & Interesting Articles ![]() Pricing

Pricing ![]() Products

Products

![]()

![]() Warranty / Service & Repair

Warranty / Service & Repair

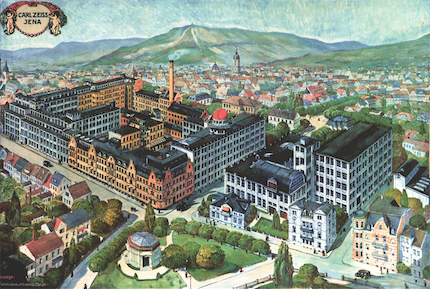

Carl Zeiss - A History Of A Most Respected Name In Optics

Preface: going on-line in 1994 this is among our first ever, and earliest on line articles about Carl Zeiss. It is written entirely with a simple text editor and hosted as another way of expressing our gratitude to those who have helped Company Seven prosper, and who have contributed (by donation or sale) to our museum exhibits.

With some of this content dating back to the times when slow dial-up Internet access was the norm, the article was originally text heavy because illustrations were by necessity kept simple and to a minimum. Over the decades we have, and will continue to, on occasion add this or that mention of or illustration of items in our archives and museum collection, this to break up the monotony of text, make corrections (with much gratitude to Dr. Wolfgang Wimmer, Director of Carl Zeiss Archives), clarify, or expand content. It was never our intent to write one comprehensive and all-encompassing history of Zeiss, that would require volumes to do it justice, but rather to explain why we at Company Seven remain grateful for and in awe of the achievements by the Carl Zeiss Foundation, and its companies.

To read this article in German, click this (Um diesen Artikel auf Deutsch zu lesen, klicken Sie hier) link to the Google Translator.

The Founders And The Zeiss Company Foundations:

From its inception through to the middle 19th century, lens making was a craft that was essentially passed on from generation to generation. Innovations had typically resulted from trial and error experimentation; this was a costly and time consuming process that could not factor in all of the possible variables in lens making materials and design. It would be left up to one who could employ scientific methods of study, and then devise the mathematical formulas to characterize the physics of optics to make the next important technological leaps possible. It would then be asked of a chemist to invent and manufacture those raw materials necessary to make the new designs possible. And it would be one man to bring this combination together to create a concern of unrivaled accomplishment.

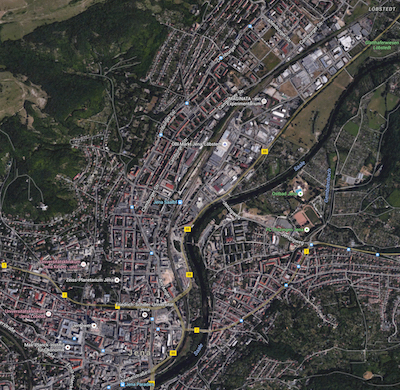

Carl Friedrich Zeiß (Zeiss) (b. 11 September 1816 in Weimar - d. 3 December 1888 in Jena) grew up in Weimar, but moved to Jena in 1834. These cities were then part of the Großherzogtum Sachsen-Weimar-Eisenach (Grand Duchy of Saxe-Weimar-Eisenach), of the Deutscher Bund (German Confederation); since 1990 they are in the State of Thüringia of Federal Republic of Germany.

Carl Friedrich Zeiß (Zeiss) (b. 11 September 1816 in Weimar - d. 3 December 1888 in Jena) grew up in Weimar, but moved to Jena in 1834. These cities were then part of the Großherzogtum Sachsen-Weimar-Eisenach (Grand Duchy of Saxe-Weimar-Eisenach), of the Deutscher Bund (German Confederation); since 1990 they are in the State of Thüringia of Federal Republic of Germany.

Right: Carl Friedrich Zeiss, (image size 23,218 bytes).

Mouse over the image to view a black and white photo taken earlier in his life (17,651 bytes).

In Jena he apprenticed in the shop of Dr. Friedrich Körner (b. 1778, d. 1848), who occupied a residential and commercial building at Grietgasse 10. While here, Carl Zeiss become well acquainted with the operation of fine tools and machinery that were used to produce microscopes and other scientific instruments. Körner was a machinist who provided such instruments to the German court. From the summer of 1835 to the winter semester ending January 1838, Zeiss attended lectures at the University of Jena where he studied mathematics, physics, anthropology, mineralogy, and optics; he completed his practicals (exams) at the Physiological Institute in Jena under Professor Schleiden. Ending his apprenticeship in May 1838 Zeiss traveled as a journeyman for some years, gaining more experience in the craftsman's shops in Stuttgart, Darmstadt, Vienna and Berlin.

Carl Zeiss had gained enough knowledge, experience and confidence that he returned to Jena on 29 September 1845 intent on building his own small business. However, in this era the administration required that prior to being licensed to do this an applicant had to prove residency and also prove competence in their chosen field. Being a student would provide the necessary prerequisite so Carl Zeiss so he enrolled in the University. On 10 May 1846 Carl Zeiss submitted the required application to the Weimar authority where he requested permission to open a mechanical workshop. His application and testing were completed, he was approved and issued the appropriate licensing and citizenship of Jena so he could proceed.

After his application was approved, on 17 November 1846 Carl Zeiss opened for business as “Carl Zeiss AG” The suffix AG is German for Aktiengesellschaft, that is German for joint-stock company, similar to a public corporation with stock holders in the United States. The first workshop was in a four story building located at Neugasse 7 in Jena, near the Saale River in the district of Thüringia in Germany. Here he commenced production of simple microscopes, measuring instruments, and other precise optical and mechanical instruments. In the first year of operation he sold twenty-three microscopes; not bad considering the state of the economy at the time and that his name was not yet well known.

In June of 1847 Zeiss had completed the move, as planned, to a larger facility at Wagnergasse 32. This three story structure would become, as was not uncommon in the era, both his residence and commercial shop location as well. It was then when Zeiss hired his first apprentice August Löber (b. 1830, d. 1912); Löber would contribute to the success and growth the C. Zeiss Jena company until retiring in about 1891. This shop was so well equipped that they were able to complete their first new microscope in September 1847. Among the customers of the budding concern was the University of Jena, for whom Zeiss made and repaired scientific equipment.

Carl’s first wife Bertha Pauline (nee Schatter, born 30 May 1827) gave birth to their son Roderich Zeiss (b. 23 February 1850, d. 4 September 1919) but tragically Bertha died at age 22 on the next day from complications of childbirth. Carl Zeiss married again, to Ottilie Trinkler (b. 28 December 1818, d. 22 August 1897) and their marriage of 1853 produced Karl Otto Zeiss (b. 25 February 1854, d. 6 October 1925) who would grow to become a medical doctor. Their other children were: daughter Hedwig Zeiss (b. 27 September 1856, d. 3 May 1938), and Sidonie Zeiss (b. 1 October 1861, d. 3 February 1920).

Zeiss began to make innovative improvements for his production microscopes and their accessories. Initially he was offering simple microscopes, but in 1857 Zeiss introduced their first compound microscope (employing both an objective lens and an eyepiece), this was designated the “Stand I”. In 1861 Zeiss compound microscopes are declared to be “among the most excellent instruments made in Germany” and he is awarded a Gold medal at the Thüringian Industrial Exhibition.

Zeiss began to make innovative improvements for his production microscopes and their accessories. Initially he was offering simple microscopes, but in 1857 Zeiss introduced their first compound microscope (employing both an objective lens and an eyepiece), this was designated the “Stand I”. In 1861 Zeiss compound microscopes are declared to be “among the most excellent instruments made in Germany” and he is awarded a Gold medal at the Thüringian Industrial Exhibition.

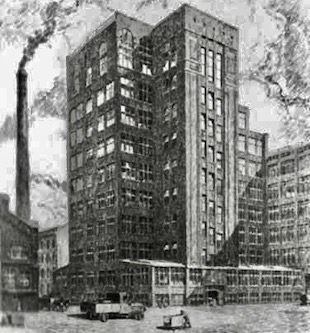

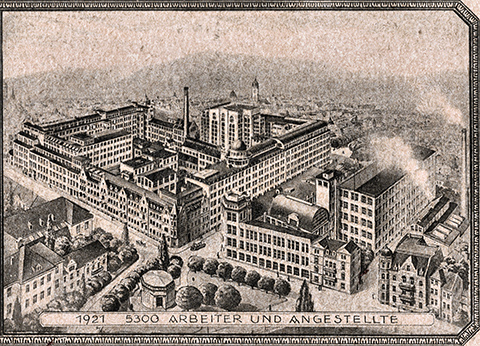

By 1864 the workshop, now with some two hundred employees, was moved to a third and even larger facility at Johannisplatz 10.

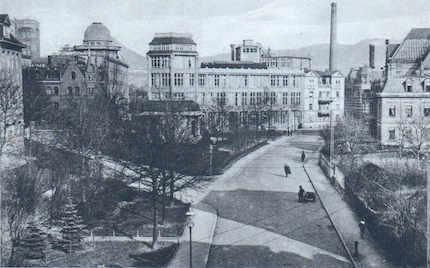

Left: the first workshop at Johannisplatz No. 10 to the left of the frame, bearing the name Carl Zeiss. Photo taken in 1867 (122,034 bytes).

Click on image to see enlarged view (261,467 bytes).

In 1866 the 1,000th new Carl Zeiss microscope is delivered. By this time the Carl Zeiss optics shop was becoming recognized throughout European scientific circles for the fine qualities of its microscopes and their accessories.

Above: Carl Zeiss Jena microscope Nr. 602/1291. The 1291st microscope, and their 602nd compound instrument made by Zeiss.

The smallest Zeiss compound microscope of the time, this is a stand Vb model with lens A or C and the eyepiece 2. This was delivered new in 1868

to Max Johann Sigismund Schultze, (March 25, 1825 - January 16, 1874) a microscopic anatomist noted for his work in Greifswald on cell theory.

From Company Seven’s collection, presently displayed at our showroom museum - and its clarity of view is still amazing (image 57,655 bytes).

Click on image to see enlarged view in png format (988,796 bytes).

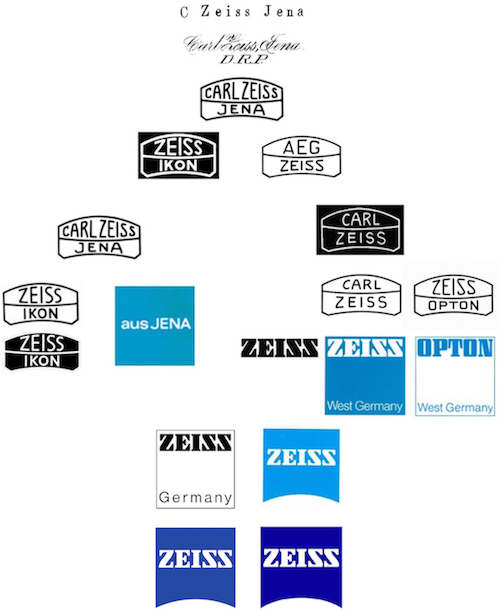

Company Seven has few resources in our archives to indicate whether or not Carl Zeiss had adopted any company trademark or not when the company commenced production. The earliest example we own of any item identified as having been made by Zeiss is the compound microscope shown above. This instrument does bear the simple “C Zeiss Jena” engraving on the slide Stage. On the Stage top and to the left of the company name are also engraved the microscope production and the series (compound microscope) serial numbers too.

Company Seven has few resources in our archives to indicate whether or not Carl Zeiss had adopted any company trademark or not when the company commenced production. The earliest example we own of any item identified as having been made by Zeiss is the compound microscope shown above. This instrument does bear the simple “C Zeiss Jena” engraving on the slide Stage. On the Stage top and to the left of the company name are also engraved the microscope production and the series (compound microscope) serial numbers too.

Right: C Zeiss Jena company trade name engraved on Stage of microscope Nr. 602/1291. Exhibited at Company Seven (47,426 bytes).

Click on image to see enlarged view in png format (106,586 bytes).

Ernst Carl Abbe (b. 23 January 1840 - d. 14 January 1095): up to this time advances in optical designs and materials relied heavily on inefficient trail and error efforts. Sometimes improvements, such as the discovery that a ceramic stirrer would be better than what was used up to then for example, came by accident. Some improvements resulted from others inventions; a new high temperature furnaces whose temperatures could be more precisely set and controlled became a vital component in making larger glass. The formulas of materials that would be melted together to form the desired glass tended to be trade secrets, or they might have been handed down to their successors. However, when some of these pioneers died likewise passed knowledge and experience.

Ernst Carl Abbe (b. 23 January 1840 - d. 14 January 1095): up to this time advances in optical designs and materials relied heavily on inefficient trail and error efforts. Sometimes improvements, such as the discovery that a ceramic stirrer would be better than what was used up to then for example, came by accident. Some improvements resulted from others inventions; a new high temperature furnaces whose temperatures could be more precisely set and controlled became a vital component in making larger glass. The formulas of materials that would be melted together to form the desired glass tended to be trade secrets, or they might have been handed down to their successors. However, when some of these pioneers died likewise passed knowledge and experience.

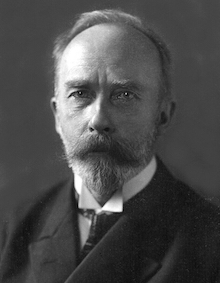

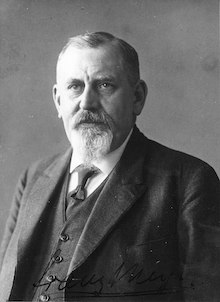

Left: Ernst Abbe (24,706 bytes).

Mouse over the image to view a black and white photo taken earlier in his life (12,901 bytes).

Realizing that the improvement of optical instruments demanded advances in optical theory Zeiss noted “the only remaining function of the working hand should be that of precisely implementing the forms and dimensions of all construction elements as determined by the design computation”. Carl Zeiss engaged Ernst Abbe (b. 23 January 1840 in Eisenach, Duchy of Saxe-Weimar-Eisenach - d. 14 January 1905 in Jena) as a free-lance research worker when he was a twenty-six years young lecturer of physics and mathematics at the University of Jena. It was Abbe who would become Zeiss partner and help launch the name Zeiss into the stratosphere of optics.

Many of those who would become the most successful minds in optics were taught at the University at Jena, and then employed at the Zeiss Works. Ernst Abbe was without doubt a most gifted individual whose accomplishments place him in that rare category of person who can be said to have a profound impact on the rapid evolution of many optical theories and products.

Abbe grew up in poverty, his father Georg Adam Abbe was a foreman in a spinning mill and worked as much as sixteen hours a day to support his family. Abbe earned his way through school in Eisenach by gaining scholarships, and with some assistance from his father’s employer. As an undergraduate Abbe studied physics and mathematics at the University of Jena (1857-1859). He went to graduate school at the University of Göttingen (1859-1861) where on 23 March 1861 he received a Doctorate in thermodynamics with the thesis “Erfahrungsmäßige Begründung des Satzes von der Äquivalenz zwischen Wärme und Mechanischer Arbeit” (Experiential Justification of the Set of the Equivalence between Heat and Mechanical Work). Abbe was employed for brief terms first as an assistant at the at the observatory in Göttingen, then the Physikalischen Verein in Frankfurt am Main (Physics Association in Frankfurt). In August 1863 Abbe joined the faculty at the University of Jena where he lectured on physics and mathematics, and later where he would serve his professorship. In 1866 Abbe was introduced to Carl Zeiss who was manufacturing microscopes and other instruments for clients including the University, Abbe became very interested in the optical challenges facing microscopy. Late in 1866 Zeiss and Abbe formed a partnership where Abbe became the director of research of the Zeiss Optical Works. Abbe laid out the framework of what would become the modern computational optics development approach. By 1869 their work produced a new patented illumination device, which provide illumination of the objects studied under a microscope in a manner superior to that of previous systems.

Among Abbe’s most significant breakthroughs was the formulation in 1872 of a wave theory of microscopic imaging that became known as the “Abbe Sine Condition”. This approach made possible the development of a new range of seventeen microscope objectives - three of these were of the immersion type, all were designed based on mathematical modeling. In Abbe’s words:

-

“based on a precise study of the materials used, the designs concerned are specified by computation to the last detail -

every curvature, every thickness, every aperture of a lens - so that any trial and error approach is excluded.”

As mentioned above, prior to the work of Carl Zeiss and Ernst Abbe lenses were made by trial and error and by repeating past proven glass and lens prescriptions. However, these objectives were the first lenses ever made that were designed based on sound optical theory considering the laws of physics. The comparatively high performance of the new Zeiss microscope objectives earned for the company international acclaim as an innovator capable of devising high performance optical products.

Abbe’s early ideas did not always advance the state of the art, one of his first calculated microscope designs proved to be inferior to that already being produced by Zeiss. This caused Ernst Abbe to redouble his efforts and resulted in his theory of image formation in the microscope, and formula for predicting the maximum achievable microscopic resolving power. This was so important an accomplishment that it was among the factors that led Carl Zeiss to partnering with Abbe on 22 July 1887, though this was backdated to 15 May 1875.

Calcium Fluorite (CaF2): since the first refractive lenses were made glass makers worked to improve glass consistency and to develop new glass types. Among transparent natural minerals evaluated were varieties of crystalline material Calcium Fluorite. Early opticians including Joseph Ritter von Fraunhofer (b. 6 March 1787, d. 7 June 1826) had found none of the crown glass types of their era could rival Calcium Fluoride for: low-dispersion, very low refractive index, wide spectral transmission, and this tended to weigh less than conventional glass.

But optical quality natural Calcium Fluorite was difficult to source. Optical lens fabricators were working to refine techniques to cut it without shattering it, then carefully grind and polish select small samples of Fluorite well enough to create lenses. We do not know exactly who was first to successfully make a lens of Calcium Fluorite, but it was likely first adopted for use in making microscope objectives. Even more challenging would have been to make one that still worked a year or more later.

Charles A. Spencer (b. 1813, d. 28 Sept. 1881) was manufacturing microscopes by 1839, and from 1854 to 1873 he also produced achromatic refracting telescopes and other related instruments. By the late 1850s he was working to improve his microscopes objectives. He devised at least one ¼-inch model that incorporates a Calcium Fluorite element; this five element objective was certainly in production by 1860. So Spencer may have been the first to successfully incorporate Fluorite in production optics. There are reports of a Spencer 1/18 immersion objective that were still considered to be corrected as well as those that would be produced decades later by Carl Zeiss and branded Apochromat. Interestingly enough, these objectives were not termed Apos by Spencer regardless, they earned Spencer international acclaim and were considered the best in their class by many. There are some of these surviving today that, if they have been cared for reasonably well, do remain functional.

A fire in the fall of 1873 destroyed the Spencer factory at Canastota. In 1877 he founded a new company “C. A. Spencer & Sons” making microscopes that would earn Spencer more international acclaim, including a Grand Gold Medal, the highest award at the Paris Universal Exposition Exposition Universelle of 1878. After his death the subsequent Spencer Lens Company would later be acquired by American Optical Company.

About twenty years after Spencer created his first high performance microscope objectives with Calcium Fluorite, Professor Abbe and Otto Schott too were studying the possibilities of using Fluorite. Their fabricators refined techniques to produce small Calcium Fluorite lens elements made well enough to create their first Fluorite oil immersion microscope objective lens, these were among their first optics for which Zeiss could justify using the characterization of “Apochromat”. Zeiss commenced to market these by 1878.

Prof. Abbe worked hard to disguise the name of this miracle glass, but the results spoke for themselves and this put Carl Zeiss Jena apochromatic microscope objectives in demand world-wide.

By 1879 there were four manufacturers who were rated by the microscopy community as preeminent in the field: C. A. Spencer and Sons of New York, Robert B. Tolles of Boston, Powell & Leland of England, and Carl Zeiss Jena in Germany.

However, unlike the proven Spencer microscope Calcium Fluorite objectives the first Zeiss microscope objectives with Fluorite lacked resilience: these could not endure humid climates, and tended to degrade just sitting in a cabinet if their desiccant was not recharged. Even modest impact might be enough to start a Fluorite element cracking. Aside from challenges of longevity, there were production hurdles that limited their practicality to very small elements.

Later Professor Abbe concluded:

- “Some of our first apochromats (but by far the fewest!) experienced some internal glass deterioration without external visible damage. The glass became turbid, the image fuzzy, the objective unusable. It turned out that some types of glass used in these systems - despite several tests in the laboratory - did not stand up in practical use.”

Consequently Prof. Abbe prompted Schott to develop new glasses that might more closely match the optical properties of Calcium Fluorite, but with manufacturing and longevity properties of glass. After numerous experiments Schott started to produce several Fluoro-Crown (or fluorine crown) glass types that enabled Professor Abbe to introduce new optics termed “Apochromats” during a July 1886 lecture at the Jena Society of Medicine and Natural Science.

The performance of Calcium Fluorite remained a gold standard in optics. But Fluorite could not be sourced in larger samples, and with properties (lack of impurities, homogeneity, etc.) good enough for making larger lens elements for photography or telescope. This would lead researchers to devise techniques after many decades of research, to actually manufacture (synthesize) Calcium Fluoride crystals.

In 1881 Dr. Roderich Zeiss, son of Carl Zeiss and his late wife Bertha Pauline, became a co-partner in the Zeiss concerns.

Otto Schott (b. 17 December 1851 Witten - d. 27 August 1935) grew up in a family that introduced him to making window glass, his father became a co-owner of a glassworks in Westphalia in 1853. He became the father of modern glass science and technology. Schott left home after gaining a masterly understanding of the state of the art to study chemical technology at the technical college in Aachen, and later at the universities of Wijrzbur and Leipzig. Schott later earned his Doctorate at the University of Jena in 1875 for his work about defects in window glass manufacturing. In late 1879, Schott wrote to Ernst Abbe describing his success in devising a technique to formulate a new glass that incorporated lithium, and later Schott sent a sample of this glass to Abbe. Schott’s work in his native town of Witten had by 1881 resulted in glass products with optical properties that up to that time had been unknown.

Otto Schott (b. 17 December 1851 Witten - d. 27 August 1935) grew up in a family that introduced him to making window glass, his father became a co-owner of a glassworks in Westphalia in 1853. He became the father of modern glass science and technology. Schott left home after gaining a masterly understanding of the state of the art to study chemical technology at the technical college in Aachen, and later at the universities of Wijrzbur and Leipzig. Schott later earned his Doctorate at the University of Jena in 1875 for his work about defects in window glass manufacturing. In late 1879, Schott wrote to Ernst Abbe describing his success in devising a technique to formulate a new glass that incorporated lithium, and later Schott sent a sample of this glass to Abbe. Schott’s work in his native town of Witten had by 1881 resulted in glass products with optical properties that up to that time had been unknown.

Right: Otto Schott (22,413 bytes).

Mouse over the image to view a black and white photo taken earlier in his life (18,219 bytes).

On 4 January 1881 Schott met with Dr. Abbe who encouraged Schott to employ a scientific approach to the determination of raw ingredients to be used in glass formulations, and the development of manufacturing techniques of what would lead to the development of more than one hundred new types of optical and industrial glasses. Together Schott and Abbe would also work to improve the raw materials mixing and glass annealing processes. In 1882 Schott moved to a new glass-making laboratory set up for him in Jena. In 1884 Schott together with Carl and Roderich Zeiss, and with Ernst Abbe,s founded the Glastechnisches Laboratorium Schott & Genossen to develop new types of optical and heat resistant glass. Later this later became the Glaswerke Schott & Genossen.

Schott developed many new glass types, a number of which are still in use including Borosilicate Crown that is also known as a BK glass. Schott’s glass innovation made possible the introduction by Zeiss in 1886 of their first “apochromate” lens, a lens with improved color correction. His company pioneered not only new glass types but improved their homogeneity, these lead to new applications and new markets including “Jenare Glass” a domestic glassware line, and glassware for laboratory and industrial uses. He would become involved with social concerns, being elected to city council of Jena where he served from 1896 to 1899.

This collaboration resulted in the Jena Glass Works of Schott becoming the prime source of glass and filter materials for Zeiss products. This research and development effort bore its first noteworthy fruit in 1886 when Zeiss marketed the first “apochromate” microscope objectives; this apochromatic microscope objective offered superior quality. Employing “fluorspar” elements this was the first use of crystal in an industrial optical application.

Ottos oldest son Rolf Schott was killed during World War I, so the family knew something of wartime loss. Otto Schott retired from his day to day activities at the glass works in 1926, and his surviving son Erich Schott who had come to work there some years prior, was promoted to head the company. Erich would lead the company through transformative years of the Depression, a second World War, and it's aftermath.

Landmarks And Transitions

By this time Zeiss microscopes and other instruments were well enough regarded to rate international representation. In the United States for example Francis J. Emmerich, originally at Maiden Lane by 1872, then Francis J. Emmerich & Son at 138 Fulton Street, New York City, and by 1889 at 43 Barclay Street, New York City, imported and distributed Carl Zeiss instruments during the 1880s until the death of the elder Emmerich in 1892.

The Zeiss company delivers its 10,000th new microscope! The founder Carl Zeiss lives to see this breakthrough, but soon afterward he died on 3 December 1888. This left Ernst Abbe as the sole owner of the company then with 250 employees and craftsmen.

In 1889 the Zeiss company publishes it’s Catalogue No. 28 describing their microscopes product line containing, per F. J. Emmerich Sr., “many new apparatus and improvements of importance.” He had some experience with an attempted fraud by Heinrich Hensoldt (b. 1856 - d. ca. 1918), and other attempts to pass inferior products on as Zeiss, so Emmerich went on to elaborate:

-

“I am of opinion that all makers should follow the example of Mr. Carl Zeiss, of Jena, whose name is distinctly engraved on every one of the objectives he produces, as from the way they are manufactured under the supervision of Professor Abbe, there cannot possible be an inferior article produced or delivered from his workshop. I may, however, add that every buyer should look out that he gets really the genuine article, and would caution him to beware of counterfeits.”

Flatteringly enough, counterfeiting of Zeiss products would continue even into the 21st century particularly when involving antique items or binoculars that resemble those made by Carl Zeiss Jena.

The Stiftung And Corporate Ideals

Abbe was interested in improving academic and research resources. His efforts resulted in the establishment of Institutes for Applied Physics and Applied Chemistry at the University of Jena. Abbe was also interested in social reforms culminating in the formation in 1889 of the “Carl-Zeiss-Stiftung” (Stiftung is the German term for an entity akin to a Foundation) to operate the various Zeiss concerns, with a mission to ensure the Zeiss firm follows the social vision of its founders. By 1889 there were some 350 employees and workers affiliated with the Zeiss company and foundation. The independence of the Carl-Zeiss-Stiftung was formalized in 1891 as Abbe (and later Roderich Zeiss) bequeathed his shares in the Zeiss Optical Works factory and the Schott Glassworks to the Stiftung.

The original constitution of the Stiftung provides that the profits of the Zeiss firms finance the growth and stability of the firms. The remainder of the profits are allocated to the foundation, that makes grants for: scientific research, cultural activities, and employee benefits programs. The number of employees, craftsmen, and workers enjoying the working conditions at Zeiss had grown to 520.

Some 685 personnel celebrated the 50th anniversary of the founding of Zeiss in 1896. This was nearly double the number of people there just seven years before, and the employment rolls would more than double again to 1,450 by 1905.

By 1900 the employment benefits at Zeiss were uncommonly good in their day, these included: an eight-hour work day, paid holidays, some forms of health benefits, profit-sharing, and retirement. It is our understanding that one provision of the Stiftung Statutes was that the top salaries at Zeiss could not exceed the average income of the workers by more than a factor of ten. Such concerns of employees’ well being was rare at the time, but it was returned to the company with increased employee loyalty and by attracting better-qualified candidates for employment.

In 1923 Schott also added his shares in the Glass Works to the Foundation.

Optical Technology Innovations Blossom

As Zeiss had proved how math and physics played key roles in developing optics, and Carl Zeiss Jena attracted mathematicians (some attracted through Abbe’s teaching work) and physicists like a magnet. Zeiss was developing experience and expertise so quickly, and had access to innovations of glass technologies if not calling for new glasses to be made, so that their engineers could adapt to new requirements sooner than most others in the photographic market. If an engineer had been working on a new idea and came up against some limit regarding lack of a glass with certain properties then he might ask Schott to look into making a new glass. If the glass was not available until a decade or more later, then Zeiss archives and files might contain prior research work that would help someone else, if not the author, resume work when a new suitable glass was developed. Or, a shelved effort might be resurrected and applied to an entirely new optical product.

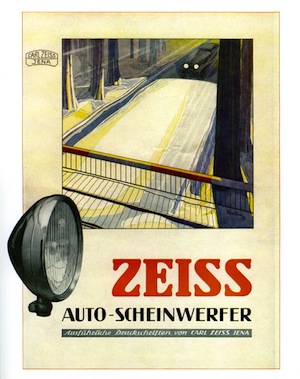

In Photography: photography too became a major factor in the increasing success of Carl Zeiss. There were many opportunities for new photographic products, especially since Kodak and others were marketing more manageable and simpler to use film cameras geared for consumers. A camera needed basic components: a lens (Zeiss designed and made these), a shutter mechanism (Abbe designed and patented), and film (no, Zeiss did not make that). Since every camera needed at least one lens this was a major market opportunity, and this is one that Zeiss came well prepared to meet. Zeiss developed lenses introducing them with names some that remain respected today by their modern descendants,

It was a Carl Zeiss Jena physicist, Dr. Paul Rudolph (b. 14 November 1858 - d. 8 March 1935), who led the effort to develop the world’s first anastigmat (or anastigmatic) lens. Every photo lens made prior to this would image in a way that photographs taken with them, under close inspection, would show one or more defects (termed aberrations in optics). The “anastigmat” was the first among a series of lenses designed for film photography that corrected astigmatism, coma, and spherical aberration. The correction of chromatism, false color that appears as a halo of violet or crimson where contrasting colors meet caused as wavelengths of light passing through glass are shifted, was less of a concern with shorter focal length lenses but improvements in glass technology to solve this in longer lenses would come later. The first of these anastigmat lenses was the Protar of 1890. This would be followed in 1895 with the Planar, the Unar of 1899, the Tessar of 1902 so sharp that it was marketed as the “Eagle’s Eye”, the Plasmat of 1918.

It was a Carl Zeiss Jena physicist, Dr. Paul Rudolph (b. 14 November 1858 - d. 8 March 1935), who led the effort to develop the world’s first anastigmat (or anastigmatic) lens. Every photo lens made prior to this would image in a way that photographs taken with them, under close inspection, would show one or more defects (termed aberrations in optics). The “anastigmat” was the first among a series of lenses designed for film photography that corrected astigmatism, coma, and spherical aberration. The correction of chromatism, false color that appears as a halo of violet or crimson where contrasting colors meet caused as wavelengths of light passing through glass are shifted, was less of a concern with shorter focal length lenses but improvements in glass technology to solve this in longer lenses would come later. The first of these anastigmat lenses was the Protar of 1890. This would be followed in 1895 with the Planar, the Unar of 1899, the Tessar of 1902 so sharp that it was marketed as the “Eagle’s Eye”, the Plasmat of 1918.

Left: Dr. Paul Rudolph (b. 14 November 1858 - d. 8 March 1935), photographic lens optical wizard of the Carl Zeiss Jena. Photo taken about 1895 (42,722 bytes).

Each innovation solved new problem or improved on performance over a prior generation; a lens might be developed for uses to cover larger and larger film formats, or a newer lens might allow faster focal ratios to shorten exposure time or reduce depth of field to increase artistic capabilities. For the consumer market a Zeiss camera or lens might have been their first introduction to the qualities of craftsmanship and performance there was coming from Carl Zeiss in Jena.

Zeiss had the means and the business acumen to know when it was time to compete, or time to acquire, and Zeiss also knew when to cooperate. By the turn of the century Zeiss lenses designs were so advanced and the name so well regarded that several of these designs were licensed by manufacturing companies overseas. Zeiss developed especially good relations with Bausch & Lomb of Rochester, New York, and Ross of London that would lead to cooperation in other areas too including binocular production.

Zeiss commenced making acquisitions to strengthen it’s position in the respective markets. In 1902 Zeiss acquired a local recent startup Palmos A.G. who was known for their Stereokamera and their Palmos 6x9 format camera, and this facility continued production as Aktiengesellschaft Camerawerk Palmos. The growth of opportunity was so extensive in the blossoming photography market that improved cooperation would be beneficial to sustain growth and innovation. So in 1909 and agreement was reached between four major German camera makers to form a new concern, Internationale Camera Aktiengesellschaft (ICA) based in Dresden. The shares of Ica were owned by the contributing companies who were:

- Camerawerk Palmos AG (Zeiss) in Jena

- Hüttig AG in Dresden

- Dr. Rudolf Krügener, Photochemisches Laboratorium und Fabrik photographischer Apparate Frankfurt-Bockenheim (Kamerawerk Dr. Krügener) in Frankfurt am Main

- Wünsche AG in Reick of Dresden

ICA products and literature were marketed as either Internationale Camera Aktiengesellschaft, ICA, Ica, or Ica-Contessa. In 1912 the G. Zulauf & Co. of Zurich joined the concern. Another well regarded manufacturer had entered into discussions, but the privately owned Heinrich Ernemann AG of Dresden elected to remain independent.

By 1914 Zeiss had become the world’s largest company involved in camera production with dozens of brands and factories, involved in production for that market at Jena, Dresden, and later in Stuttgart and Berlin. This would lead to great accomplishments and many innovative products bearing distinguished legacies, these would include Zeiss Ikon formed in 1926. The famous Contax brand would come about in 1932 under the tenure of Dr. Ing. Heinz Küppenbender.

Binoculars and Porro Prisms: telescopic lenses gather light and form one image that is captured onto film or presented to an eyepiece. Because of how light is bent passing through the objective (front) lens the image appears upside down and rightsize up. It was about in 1850 when the original image erecting air-spaced paired Porro Prism was devised by an Italian Ignazio Porro (1801-1875). This invention presents a corrected image (rightsize up, and correct left to right). Furthermore, as the light path through the two prisms can take up a notable distance between the objective lens and eyepiece, this results in an instrument with a more compact form than traditional longer-barreled arrangements of that era.

Binoculars and Porro Prisms: telescopic lenses gather light and form one image that is captured onto film or presented to an eyepiece. Because of how light is bent passing through the objective (front) lens the image appears upside down and rightsize up. It was about in 1850 when the original image erecting air-spaced paired Porro Prism was devised by an Italian Ignazio Porro (1801-1875). This invention presents a corrected image (rightsize up, and correct left to right). Furthermore, as the light path through the two prisms can take up a notable distance between the objective lens and eyepiece, this results in an instrument with a more compact form than traditional longer-barreled arrangements of that era.

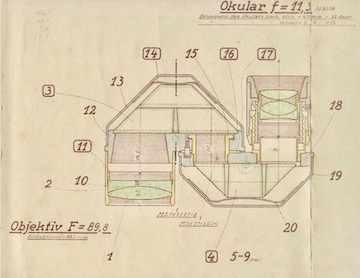

Among the first notable optical accomplishments by the Carl Zeiss works when by 1870 Abbe had independently reinvented his own image erecting Porro prism system, this is sometimes referred to as the “Porro-Abbe” design. By 1873 a working prototype instrument had been completed. However, due to the limitations imposed by the available types of crown glasses at the time, Abbe could not proceed with a producible design, so an improved crown glass was among Abbe's wish list items. By 1888 Schott improved the optical characteristics of crown glass to a point that Abbe resurrected the earlier project; by 1893 he had created and patented (back dated to July 9 at the German Imperial Patent Office) a 8x 20mm “binocular telescope with increased objective separation”. Abbe employed the improved glass prisms in an air-spaced arrangement, this in the form of the now traditional Porro binocular. The arrangement of two Porro Prisms allows for a wider separation between the two objective (front) lenses. This provides significant improvements over then competing designs, especially in that it resulted in markedly improved depth perception. This patent remained in force until 1908.

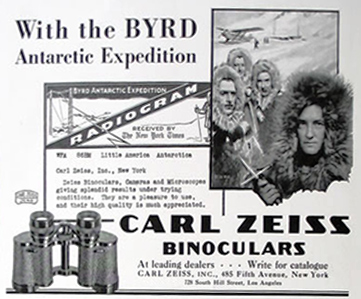

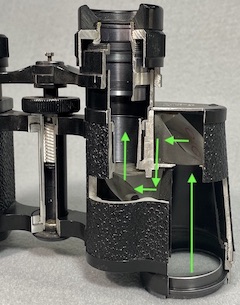

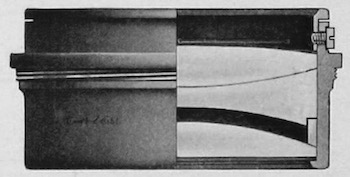

Right: Carl Zeiss Jena 8x 30 Deltrintem binocular cutaway, close up view of focus and hinge, right barrel with doublet achromat objective lens, prism housing, and eyepiece less these lens elements (37,850 bytes).

Note the paired Porro Prisms with one rotated 90° to the other in the prism housing, and the objective doublet lens. For clarity the simplified light path through the prisms is shown in lime green.

From Company Seven’s collection, exhibited at our museum.

Click on image to see enlarge view (81,199 bytes).

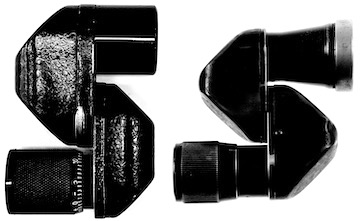

The production of Porro prism binoculars at Carl Zeiss Jena commenced in 1894 with their introduction of the 4x 11 mm, a 6x 15 mm, and 8x 20 mm models of their Feldstecher (binocular) series. Zeiss records indicate that over that first year of production they assembled at total of 205 binoculars. In 1895 Carl Zeiss Jena would introduce their 10x 25 mm, a greater diversity of models and their variants would follow.

Left: among the very earliest production Carl Zeiss Jena binoculars is this 4x Feldstecher, feldstecher being one of the terms in German for binocular (24,738 bytes).

From Company Seven’s collection, exhibited at our museum.

Click on image to see enlarge view (76,899 bytes).

Each binocular was furnished with a hard leather carry case, the flap lid that fastened to a post at front of the case. The binocular included a leather carry strap that fastened to strap loops that were, in early models, bolted to the left and right prism housings. The carry straps featured a slots cut through each end, these accommodate barbell-shaped fasteners; this leather straps and fasteners arrangement was adopted by other binocular makers but were discontinued by Carl Zeiss, Leica (Leitz), and most others the turn of the next century; however, suitable third party replacement carry straps remain available even today. The carry case too was furnished with a wider carry strap, with buckle arrangement suitable for varying overall length. Some carry cases also featured belt loops, but these loops tended to be more common for the military models.

- Carl Zeiss Jena branding,

- country of origin,

- no designation or Feldstecher, feldstecher being one of the terms in German for binocular,

- the magnification; the earliest models bear a simple number on the Bridge Cap (facing the observer) such as 4, or 6 and with a period to avoid confusing 6 for 9. Later early production binoculars may binoculars bear either Vergr.=4, Vergr.=6, or Vergr.=8 for example engraved on the right Prism Cover.

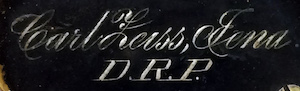

The trade name applied onto the earliest production binoculars is “C. Zeiss, Jena”, and that is engraved on the left prism cover while the country of origin is engraved on the right prism cover. The labeling scheme was soon changed to “Carl Zeiss, Jena” and with the country of origin (D.R.P.) on the left prism cover, while the model designation and the magnification information were applied on the right prism cover.

The trade name applied onto the earliest production binoculars is “C. Zeiss, Jena”, and that is engraved on the left prism cover while the country of origin is engraved on the right prism cover. The labeling scheme was soon changed to “Carl Zeiss, Jena” and with the country of origin (D.R.P.) on the left prism cover, while the model designation and the magnification information were applied on the right prism cover.

Above right: the Carl Zeiss, Jena trade name applied in cursive script, with the country of origin referred to as D.R.P. (88,448 bytes).

Photograph of binocular manufactured in 1896, exhibited at Company Seven’s showroom.

The country of origin was referred to by the engraved letters D.R.P.*. Some binoculars were made specifically for distribution by a Zeiss office or retailer in a foreign country, so that binocular may bear the name and city of a representative in London or in Lisbon for example, a binocular may even bear the engraved name of the retailer who distributed it. Some binoculars were personalized, so in addition to the factory and retailer information a binocular may also bear an engraving of the owner’s name, possibly even an address too.

* The country of origin labeling is D.R.P., the abbreviation for Deutsches Reichspatent that literally translated to German Empire Patent. D.R.P. indicates the item was protected by a 15 year term patent filed with the Kaiserliche(s) Patentamt (Imperial Patent Office). This was the official document, legal within all German states, based on the Reichspatentgesetz law authorized on 25 May 1877 that went in effect 1 July 1877 until 1945. The item so labeled could have been manufactured by the patent holder, or it could have been made under license by some other maker. In 1919 the patent registration office became the Reichswarenzeichenregister (R.W.Z.R., for Empire Trademark Register), then in 1949 Deutsche(s) Patentamt, and after reunification this became Deutsches Patent- und Markenamt (D.P.M.A.) in 1998.

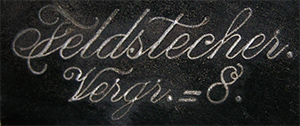

So their 8x 20 mm binoculars made for the civilian market in this era likely bear Feldstecher, and below that Vergr. 8.. In this era the markings did not indicate the lens diameter (aperture), that information is common on later production Zeiss and most other binoculars too and is expressed in millimeters.

So their 8x 20 mm binoculars made for the civilian market in this era likely bear Feldstecher, and below that Vergr. 8.. In this era the markings did not indicate the lens diameter (aperture), that information is common on later production Zeiss and most other binoculars too and is expressed in millimeters.

Right: labeling of a Carl Zeiss Jena binocular made in the mid 1890s era bearing Feldstecher and below that Vergr. 8. (111,390 bytes).

Up to this time the binoculars available in the marketplace were of the comparatively bulky and primitive Galilean optical arrangement, so as the newer and more compact Porro prism style binoculars made by Zeiss, Goerz, and others too came onto the consumer market they were sought after. But given the income of the average worker in the day, the cost of a new Zeiss Porro binocular could approach or exceed one month of wages. Civilians, military officers, and others with the means to afford it would acquire their own Porro binocular, and as their peers became acquainted with them then this too promoted more demand.

The military organizations in particular was a market niche for binoculars and one that could allocate funds, pretty much at will, to acquire equipment in some quantity; Carl Zeiss recognized this, and so he marketed to them and successfully negotiated contracts to provide them with Zeiss binoculars. The military binoculars manufactured by Zeiss in this era will bear a model designation with the prefix D. F., this is the abbreviation for Dienstglas Feldstecher; literally this translates into English as “field engraver”, but the meaning was more like ‘service glass binocular’.

The military organizations in particular was a market niche for binoculars and one that could allocate funds, pretty much at will, to acquire equipment in some quantity; Carl Zeiss recognized this, and so he marketed to them and successfully negotiated contracts to provide them with Zeiss binoculars. The military binoculars manufactured by Zeiss in this era will bear a model designation with the prefix D. F., this is the abbreviation for Dienstglas Feldstecher; literally this translates into English as “field engraver”, but the meaning was more like ‘service glass binocular’.

The first effort by Carl Zeiss to enter the military binocular market was the production of their ‘O.D.F. 95’, a 6x 15 mm made in 1896 specifically for officers; they were likely the only people in the military who could either personally afford to buy them or who had the clout to have them procured them through government channels.

Left: Carl Zeiss Jena O.D.F. MODEL 95, a 6x 15mm Offizier Dienstglas Feldstecher bearing military SN 2174, and production SN 2338 made in 1896 (24,349 bytes).

From Company Seven’s collection, exhibited with it’s original leather case (in amazingly good condition) at our museum.

Click on image to see enlarge view (85,313 bytes).

Carl Zeiss Jena was among the few companies to make this concept work when they introduced a new innovative binocular late in 1895, these are labeled “Marine-Glas”. This new binocular derived from their 10x 25 mm model, while both feature the same 25 mm objective lens the Marine-Glas is useable at 5x and by rotating the turret over each prism cover the user could dial another eyepiece in-line to operate at 10x. So the Marine-Glas prism covers bear the labeling “m. Revolver”, and “Vergr.=5 - 10”. They show 6.8° und 4° degree actual fields of view. The focus are individual, typical of marine models for better sealing, so to focus these the user would rotate each eyepiece to set them to suit. The binocular barrels are cylindrical and each incorporate the objective lens, prisms, and turret with eyepieces. The barrels are leather covered, in brown or black. While the tubes and body were constructed with nonferrous metals, largely of brass and so these are rather hefty at 1.2 kg. (2.6 lbs). The Marine-Glas were produced at Carl Zeiss Jena, and distributed through military and civilian channels through 1907.

Carl Zeiss Jena was among the few companies to make this concept work when they introduced a new innovative binocular late in 1895, these are labeled “Marine-Glas”. This new binocular derived from their 10x 25 mm model, while both feature the same 25 mm objective lens the Marine-Glas is useable at 5x and by rotating the turret over each prism cover the user could dial another eyepiece in-line to operate at 10x. So the Marine-Glas prism covers bear the labeling “m. Revolver”, and “Vergr.=5 - 10”. They show 6.8° und 4° degree actual fields of view. The focus are individual, typical of marine models for better sealing, so to focus these the user would rotate each eyepiece to set them to suit. The binocular barrels are cylindrical and each incorporate the objective lens, prisms, and turret with eyepieces. The barrels are leather covered, in brown or black. While the tubes and body were constructed with nonferrous metals, largely of brass and so these are rather hefty at 1.2 kg. (2.6 lbs). The Marine-Glas were produced at Carl Zeiss Jena, and distributed through military and civilian channels through 1907.

Left: Carl Zeiss Jena “Marine-Glas” underside perspective showing the cylindrical body, the turrets and the carrying strap loops. This image contributed by W. Werner as Company Seven does not have one of these among our exhibits (72,106 bytes).

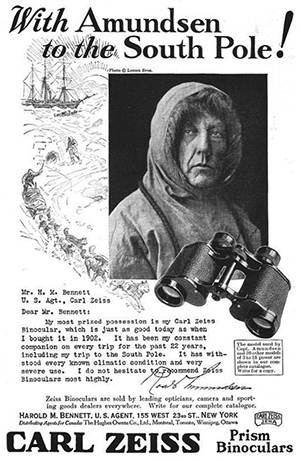

Years later a Marine-Glas earned some good international publicity for Carl Zeiss Jena. Admiral Marquis Tōgō Heihachirō (b. 27 January 1848, d. 30 May 1934) was the Commander-in-Chief of the Combined Fleet of the Imperial Japanese Navy who led the Japanese fleet to victory during the Russo-Japanese War of 1904-1905. The Admiral is depicted in a famous painting, and in statues too, holding his distinctive Zeiss turret binocular on the Compass Deck above the Bridge of the IJN Battleship Mikasa at the start of the decisive Battle of Tsushima in May 1905.

Years later a Marine-Glas earned some good international publicity for Carl Zeiss Jena. Admiral Marquis Tōgō Heihachirō (b. 27 January 1848, d. 30 May 1934) was the Commander-in-Chief of the Combined Fleet of the Imperial Japanese Navy who led the Japanese fleet to victory during the Russo-Japanese War of 1904-1905. The Admiral is depicted in a famous painting, and in statues too, holding his distinctive Zeiss turret binocular on the Compass Deck above the Bridge of the IJN Battleship Mikasa at the start of the decisive Battle of Tsushima in May 1905.

Right: Admiral Tōgō on the Compass Deck above the bridge of IJN Mikasa, at the beginning of the Battle of Tsushima on 27 May 1905. The signal flag being hoisted represents the letter Z, which was a special instruction to the Fleet. Painting by Tōjō Shōtarō (b. 1865, d. 1929). There is some artistic license here, no officer would wear their steel sword near the compass of a ship, this to avoid distorting it (72,106 bytes).

Click on image to see enlarged view (1,077,534 bytes).

The Admiral's Zeiss brown leather-covered Marine-Glas remains on public exhibit aboard the battleship Mikasa, a permanent memorial at Mikasa Park in Yokosuka, Japan. In 2017 the binocular was conserved by Carl Zeiss technicians, and on 5 July 2017 it was returned to the curators of the Mikasa by the CEO of Carl Zeiss, Ltd. (Japan).

Subsequently Zeiss obtained military contracts to deliver more 6x 15, and their 8x 20 binoculars, designated the ‘D.F. 6x’, and the ‘D.F. 95’ (8x), these commenced deliveries in 1897 with about five-hundred total being produced. Other very early Zeiss models made for the military may bear designations identifying the organization they were intended for, these include the ‘Fussartillerie D.F. 6x’ (Foot artillery 8x) exhibited at Company Seven.

As with rifles and many other military goods of the time, a model design finalized in 1895 might be in production for a decade or more. So a Model 95 binocular might have been manufactured in 1896, 1897 or even years later, the only way to date them is by their production Serial Number. The binoculars made by Zeiss specifically to fulfill for military use or for government contracts were similar to those made for the civilian market, these all tend to feature the more rugged Individual Focus (I.F.) mechanisms arrangement. The sales to this market became an important aspect, growing steadily by 1900 to about five times what were sold in 1897, and that helped Zeiss to prosper and to develop even more new products.

Above: Carl Zeiss Jena D.F. MODEL 95, an 8x 20 mm binocular of the model series made between 1897 to 1907 (107,641 bytes).

The military SN 1249 and production SN 6256 indicate this is among an estimated nine-hundred MODEL 95 contracted in 1897

out of a total production that year of about 4,161 binoculars made. Note the distinctive sloped prism covers.

From Company Seven’s collection, exhibited at our museum.

Click on image to see enlarged view (168,230 bytes).

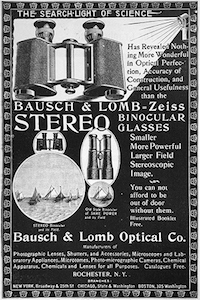

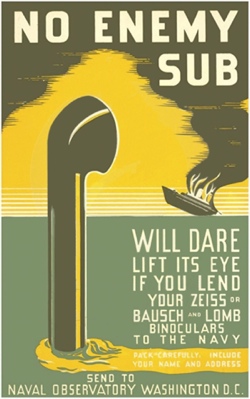

By the end of the 19th century Zeiss had negotiated limited partnership agreements or alliances with several manufacturing companies overseas. Among these was “Bausch & Lomb Optical Co.” of Rochester, N.Y., whom since 1892 had agreed to purchase components, and manufacture complementary optical products or copies of Zeiss product designs under license. This would become a triad after Saegmuller Company of Washington, D.C. was signed onto the alliance, by the Spring of 1905 Saegmuller would merge with Bausch & Lomb Optical Co. moving their facilities to Rochester. Consider that prior to the introduction of the Federal Income Tax in 1913 the United States government relied on income from import tariffs to generate much of its operating revenue. Sometimes having a product made or assembled within the country where it would be sold allowed the bypassing of expensive import tariffs.

By the end of the 19th century Zeiss had negotiated limited partnership agreements or alliances with several manufacturing companies overseas. Among these was “Bausch & Lomb Optical Co.” of Rochester, N.Y., whom since 1892 had agreed to purchase components, and manufacture complementary optical products or copies of Zeiss product designs under license. This would become a triad after Saegmuller Company of Washington, D.C. was signed onto the alliance, by the Spring of 1905 Saegmuller would merge with Bausch & Lomb Optical Co. moving their facilities to Rochester. Consider that prior to the introduction of the Federal Income Tax in 1913 the United States government relied on income from import tariffs to generate much of its operating revenue. Sometimes having a product made or assembled within the country where it would be sold allowed the bypassing of expensive import tariffs.

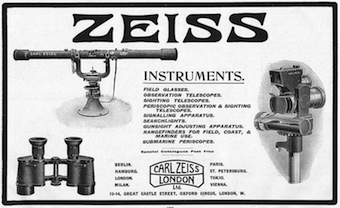

Left: Bausch & Lomb Optical Co. The Search-Light of Science advertisement published in 1899 featuring their “Zeiss Stereo Binocular Glasses” (54,670 bytes).

Click on image to see enlarged view (297,298 bytes).

These products were made well, they were marketed widely to the civilian consumer and industrial markets and to the U.S. military, and sold in such quantities that even today it is not uncommon to find a used binocular for sale bearing the engraving of “Bausch & Lomb Co.” as the maker, along with a reference to a Carl Zeiss Patent or Zeiss Prisms.

While the Zeiss Porro arrangement patent expired in 1908, the design had an appearance that for many decades later, after the patent expired, would be copied by many other makers of binoculars and these would be marketed as a “Zeiss type”, or “Zeiss design” binocular.

Porro and Zeiss Stereo Microscopes: the reputation of Carl Zeiss Jena originally was built on their production of microscopes. Over the decades Zeiss continued to improve them as the company advanced microscope technology, and Zeiss increased the diversity of their models and accessories. Stereoscopic microscopy, employing a pair of similar eyepieces with matching objective lenses, was first developed in 1671 by Cherubin d'Orleans. However, the d'Orleans arrangement reversed the image, with the left eye observing what was in the right barrel and so forth; confusing for many and limited by glass and design tech of the era. Decades later others attempted to produce stereoscopic images. Francis Herbert Wenham of London employed one objective feeding a beam splitter to fee two eyepieces; still not true stereo perception and with image qualities limited by glass tech of that era.

In 1892 Horatio S. Greenough, an American biologist then residing in Paris, suggested a promising concept for Abbe, by the end of 1897 the first stereomicroscope ever made providing true three-dimensional views was completed at Zeiss. The arrangement became known as a “Greenough Optical Train” that at first glance appears to be two microscope optical assemblies, each complete with its own objective lens and eyepiece but paired and aligned alongside. To change magnifications the user would change the provided paired objective lenses. This arrangement stimulates both eyes with one complete bright image (not reduced by beam splitting) and provides improved spatial resolution. Furthermore, with a three dimensional quality this allows the observer to judge depth, much as is perceived by a human with unaided binocular vision when observing a subject from a distance of bout 25 cm.

In 1892 Horatio S. Greenough, an American biologist then residing in Paris, suggested a promising concept for Abbe, by the end of 1897 the first stereomicroscope ever made providing true three-dimensional views was completed at Zeiss. The arrangement became known as a “Greenough Optical Train” that at first glance appears to be two microscope optical assemblies, each complete with its own objective lens and eyepiece but paired and aligned alongside. To change magnifications the user would change the provided paired objective lenses. This arrangement stimulates both eyes with one complete bright image (not reduced by beam splitting) and provides improved spatial resolution. Furthermore, with a three dimensional quality this allows the observer to judge depth, much as is perceived by a human with unaided binocular vision when observing a subject from a distance of bout 25 cm.

Right: Carl Zeiss Jena Greenough Optical Train stereo microscope (21,613 bytes).

Note the cylindrical Porro prisms housings, these correct the orientation of the image that otherwise would be upside down and reversed left to right.

Click on image to see enlarged view (61,428 bytes).

A side benefit of binocular observing is the reduced impact of distracting 'floaters' moving within the eye; a particular nuisance for older observers. Floaters are clumps of collagen fibers that form in the vitreous jelly-like substance within the eyeball. As the eye moves the floater(s) drift within and cast tiny shadows across your retina, so you perceive this out of focus debris moving along but you cannot keep them centered or focus sharply on them. When observing an object with binocular vision then the brain tends to averages these out.

The Greenough arrangement provides a true stereo perception, this differs from a binocular microscope that employs only one objective lens focused on the object of study with a beam splitter to divert the light from the one image, then feed it on to two eyepieces. It would not be until 1957 when the American Optical Company introduced their Cycloptic® Stereomicroscope that the Greenhough design would be superseded.

To this day many microscopes are available in monocular or in a binocular arrangement, but few are true stereo systems built upon parallel optical trains. There are microscopes made by Carl Zeiss that are binocular, and some marketed as stereo microscopes that include the Carl Zeiss “Stemi” series. Some binocular heads feature an additional port to accept a camera, this being referred to as a trinocular arrangement. The Carl Zeiss industrial and educational microscopes tend to be an adaptable modular arrangement, where any one of several binocular (eyepiece tube) or trinocular (termed phototube by Zeiss) heads can be attached to the stage. While most standard Zeiss some heads show an image that is erect but reversed left to right, there are some heads made incorporating image-erecting optics.

As an important aside, astronomical telescopes rarely incorporate image erecting optics as any unnecessary loss of light or reduction of resolution is a greater concern than observing an image that has been modified to appear rightsize up and correct left to right. To an astronomer it does not matter if the Moon, a planet or a star appear right side up or correct left to right, as long as they are as bright and clear as possible.

Martin's Favorite Zeiss Division Is Founded

Dr. Max Paulÿ (b. 15 November 1849, d. 26 April 1917) was an industrialist, and optician. His background is quite a story of experimentation and innovation. I offer a bit more personal background herein about Paulÿ as what is published seems inadequate given his contributions to building the foundations of Carl Zeiss Jena's Astro Division.

Johannes Gustav Max Paulÿ was born at Halle an der Saale (Halle, on the Saale River), a city in what was then the Prussian Province of Saxony in what would be in 1850 the reestablished Deutscher Bund (German Confederation), and after 1871 the Deutsches Kaiserreich (German Empire). His first four decades were largely spent in a central region of Germany residing in what were then the Duchy of Anhalt, Saxony, Brandeburg, and Prussia. He was described as a frail boy, the eldest of the three siblings in a family of five. His father Gustav Adolph was bright but appears to have lacked some stability of mindset and temperament, at times with a violent disposition even with wife Marie Louise (née Heffter); these characteristics made maintaining long term employment a challenge. Regardless of the family environment, by age 4 Max was demonstrating uncommonly good mechanical aptitudes.

In 1858 Paulÿ was attending the Frank School in Halle. A family relocation to the west in 1859 found him attending the elementary school in Harzgerode, in the Duchy of Anhalt. In 1862 he was enrolled in the secondary school of the orphanage in Halle, far from his home. In 1863 he was enrolled in yet another secondary school in Halberstadt in the Province of Saxony, to the north of Harzgerode.

Despite being an excellent student, in 1866 father apprenticed Max to work for a locksmith Dittmar, in Harzgerode; this would nurture his understandings of metals and machining. The following year Max was employed as a locksmith at “Billeter & Klunz Handelsgesellschaft”. This was a partnership company founded in April 1857 by machinist Heinrich Billeter and blacksmith Wilhelm Klunz at Aschersleben in the Province of Saxony, about 20 km northeast of Harzgerode. Their company would grow to become a large machine tool factory and iron foundry. It is noteworthy that among the equipment they were involved producing were beet washers. Paulÿ subsequently studied at the universities in Berlin, and Halle, and at the Technical University in Berlin.

With his experience in machinery and its production, and likely with knowledge of beet washers gained while at Billeter & Klunz, Paulÿ was employed by 1878 managing Zuckerfabrik Brottewitz, a sugar and beet factory founded in 1872. This was near the village of Brottewitz close to the Alte Elbe River, and a few kilometers north of Mühlberg in the Province of Brandenburg.

With his experience in machinery and its production, and likely with knowledge of beet washers gained while at Billeter & Klunz, Paulÿ was employed by 1878 managing Zuckerfabrik Brottewitz, a sugar and beet factory founded in 1872. This was near the village of Brottewitz close to the Alte Elbe River, and a few kilometers north of Mühlberg in the Province of Brandenburg.

Right: Max Paulÿ with his wife Klara, née Küttner (54,670 bytes).

Click on image to see enlarged view (297,298 bytes).

On 8 September 1881 Max and Klara Eugenie Küttner were married in Dresden, then in the Kingdom of Saxony. Their marriage record mentions his employment in factory management, and his “Doctor Philosophiae”.

From an early age Paulÿ had been fascinated by the night sky. By the 1880s he was studying practical optics, then set up his own laboratory in the in the basement of his house. In 1885 while attending the Industrial and Trade Exhibition at Görlitz, Silesia, Paulÿ observed then studied a reflecting telescope owned by Mr. v. Schlicht. The telescope had been manufactured by Mr. G. Meiβner in Potsdam. This inspired Paulÿ to visit Potsdam where he met Mr. G. Meiβner who helped Paulÿ learn more about optical surface preparation, and the application of reflective coatings. This inspired Paulÿ to not only study work of others, but build his own small scale optical production and testing apparatus so that he could actively become involved with his own experiments. Two assist with the work, her persuaded two employees of the sugar factory to help him: August Shäfer, a blacksmith who would handle mechanical fabrication, and bricklayer Karl Tauchnitz to assist with optical grinding and figuring.

Paulÿ invented methods and equipment for rough grinding glass mirrors, lenses, and prisms. He examined the materials and the surfaces carefully, and making notes to help refine his techniques. He improved tolerances, fashioning measuring equipment so he could critically verify the desired lens curves and thicknesses. He learned how to recognize, then compensate for, slight variations that were typical in the glass materials made in that era. For lens designs Paulÿ relied on opticians and mathematicians who could calculate the radii and other parameters. When making the element he would pay special attention to getting the radius of curvature at the various zones to be nominal, even developing techniques to head off some problems before they might need remedy. He also came to understand the effects of temperature changes on refractive lens elements and of cementing media, and impacts of mounting techniques. So he avoided designs that necessitated cementing lenses together unless absolutely necessary and developed improved ways of holding a lens in place. Within a couple of years he was producing as an enthusiast, a series of telescope lenses and mirrors, prisms, and auxiliary optics, some that rivaled the qualities of what a professional factory might offer.

The disciplined professionalism of his research, the diligence, led to his results that impressed many of his contemporaries and astronomers too. Consequently, a demand for his products developed. Soon he was not only fabricating optics for his own telescopes and experiments, but was producing for opticians as well as for other enthusiasts. In several instance his generosity to some who could not pay was noted, Paulÿ seemed content to help others in his pursuits, and no doubt their constructive feedback was valued.

In 1886 Paulÿ completed a 6-inch objective for the O'Gyalla Observatory, a private observatory of the astronomer Mikulás Konkoly-Thege, then in Austria-Hungary; this now the Hurbanovo Observatory, an active public observatory with a planetarium, in Hurbanovo, Slovakia. Paulÿ also produced two 10-inch objectives for the directors of the Observatories of O'Gyalla, and of the Hérény Astrophysical Observatory founded by Hungarian astrophysicist Eugen (Jenő) von Gothard. Paulÿ must have been doing something right to inspire an astronomers some hundreds of miles away to trust his optics.

In 1887 Johannes Gustav Max Paulÿ was admitted to membership of the “Astronomischen Gesellschaft” (Astronomical Society) in Germany. He was then still listed as a factory director, then residing in Mühlberg a.E. He still took pride in producing what he characterized as the finest sugars. While still with at Zuckerfabrik Brottewitz, in 1889 he invented the “Paulykocher”, a pressure cooker that improved efficiency of the process of evaporating liquids thus reducing the amount of coal formerly required, by about 30 percent; Paulÿ was 'green', before it was politically correct.

In 1888 Paulÿ completed the production of his own personal 8-inch refracting telescope. The lens was designed by his friend Miklós Konkoly-Thege. Paulÿ contemporary obituary mentioned “At the beginning of the 1890s, the 8-inch telescope was mounted for his own observatory based on designs by his friend von Konkoly, and a primitive dome was built. A transit instrument by von Gothard and a Strasser pendulum clock completed Paulÿ's small observatory, where the sun and planets were diligently observed, but which primarily served to test new instruments.”

-

As a side note, we at Company Seven come across mentions in literature from this era of “Parisian inches”. At 27.07 mm in length, the Parisian inch is 1.066x longer than the 25.4 mm US/English inch. So when we read mentions of his 8 inch telescope, consider we could, by our standards of measure, be discussing an 8.53-inch aperture telescope. An early achromatic refracting telescope, publicized as a 9-inch f/18 was in 1846 used by Johann Gottfried Galle (9 June 1812 - 10 July 1910) and Heinrich Louis d'Arrest (13 August 1822 - 14 June 1875) at Berlin Observatory to confirm the planet Neptune, to within 1° of the position predicted by the mathematical calculations of French astronomer Urbain Jean Joseph Le Verrier (11 March 1811 - 23 September 1877). This refractor is also described as a 24.4 cm (9.6-inch), by others as 25 cm (9.8-inch),s making it hard to reconcile the advertised discrepancies. In some instances it may be the descriptions were rounded up or down for convenience, or simply mistaken.

Initially Paulÿ with his assistants had devised grinding and polishing apparatus that were belt-driven and powered by hand or foot. By the early 1890s the machines in the basement of his house were motorized. In 1895 he completed a polishing machine capable of working optical surfaces up to 600 mm (23.6 inches) diameter.

Elsewhere in Jena, Dr. Otto Schott was working to develop and refine new glass types for Carl Zeiss Jena, but the small sizes of the raw blanks to produce the tiny microscope elements hindered evaluating them for larger applications. Schott became acquainted with Paulÿ, and would on occasion send larger blocks of glass to him for experimentation. It was Paulÿ who suggested casting these blanks not as squares but in cylindrical forms, resulting in less work and less waste. Paulÿ evaluated several new glass types from Schott AG and although at times he might attain the desired results, he documented subtle inconsistencies of these first examples of glass. Schott AG appreciated the feedback as this helped them to improve their products.

Between 1891 to 1894 Paulÿ completed several telescopes including: a 7-inch apochromat for the Observatory in Jena, a 6-inch Apo for the Urania Society of Berlin, and in 1893 a 175 mm (6.9 inch) Apo for observations by Spiridon Gopčevič.

Paulÿ had grown the sugar factory business, expanded his factory facilities, and while maintaining his high standards. But he had never been a model of physical fitness and health and like many others who were involved with fabrication that involved heavy metals (such as in glass) and materials in polishing compounds, after several years he showed signs that prompted his physician to recommended Paulÿ taper his activities. He had reached a fork in the road where one path continued on his prosperous sugar and beet business, the other on a path with optics that lead to the unknown. As Paulÿ had reportedly concluded before, “Zucker machen könne auch ein anderer, große Linsen schleifen aber nicht” (“Anyone else could make sugar, but not grind large lenses”). Paulÿ elected to retire from the sugar business to continue working with optics.

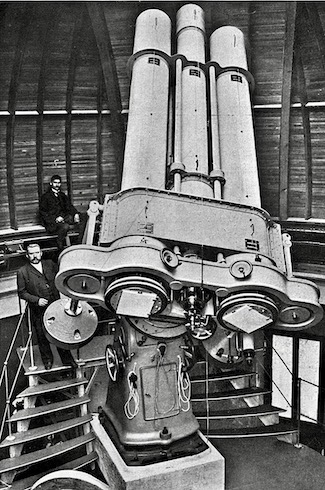

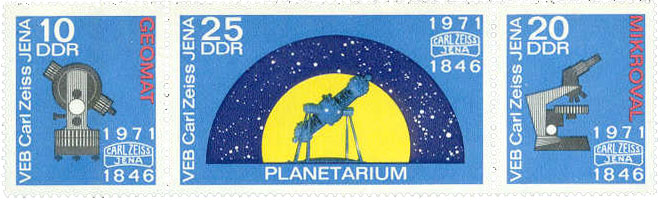

Fa. Carl Zeiss, Abteilung Astronomie: Paulÿ relocated to Jena where he collaborated with teachers, engineers and technicians, and here he met Ernst Abbe. Abbe respected Paulÿ's accomplishments, his intellect, and managerial skills. Abbe was particularly intrigued by the work Paulÿ had done to manufacture optics suitable for astronomical telescopes. It had only been a few years since Carl Zeiss Jena commenced the design and production of sporting optics (binoculars, field telescopes, etc.), that department was new and blossoming when in 1897 Abbe persuaded Paulÿ to join Carl Zeiss Jena in a partnership to establish another new department. This would be the “Fa. Carl Zeiss, Abteilung Astronomie”, translating to English as Factory Carl Zeiss, Astronomy Department, established 1 April 1897. This would specialize in the design and production of all components of astronomical telescopes, including their optics and mechanical components, and their accessories including oculars, astrophotography cameras, binocular telescopes, large binoculars, and specialized related scientific instruments.

Fa. Carl Zeiss, Abteilung Astronomie: Paulÿ relocated to Jena where he collaborated with teachers, engineers and technicians, and here he met Ernst Abbe. Abbe respected Paulÿ's accomplishments, his intellect, and managerial skills. Abbe was particularly intrigued by the work Paulÿ had done to manufacture optics suitable for astronomical telescopes. It had only been a few years since Carl Zeiss Jena commenced the design and production of sporting optics (binoculars, field telescopes, etc.), that department was new and blossoming when in 1897 Abbe persuaded Paulÿ to join Carl Zeiss Jena in a partnership to establish another new department. This would be the “Fa. Carl Zeiss, Abteilung Astronomie”, translating to English as Factory Carl Zeiss, Astronomy Department, established 1 April 1897. This would specialize in the design and production of all components of astronomical telescopes, including their optics and mechanical components, and their accessories including oculars, astrophotography cameras, binocular telescopes, large binoculars, and specialized related scientific instruments.

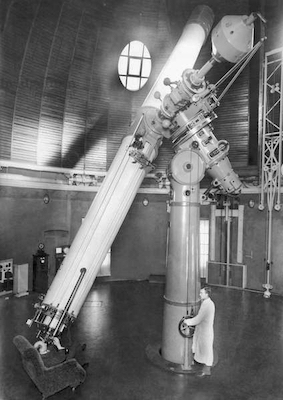

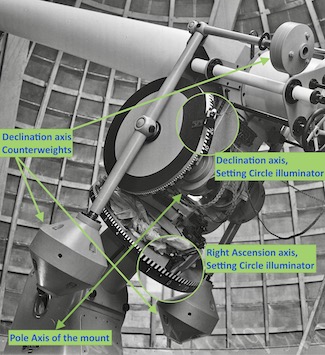

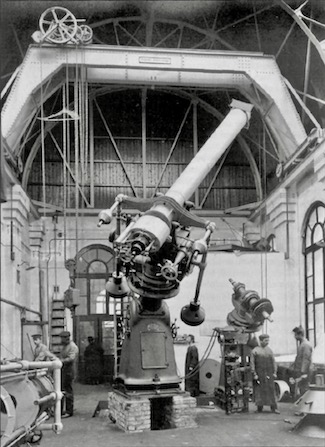

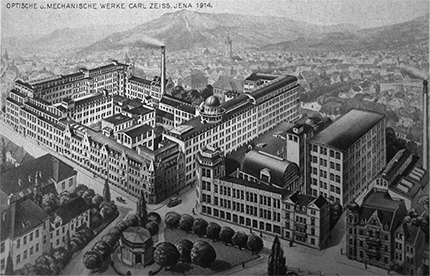

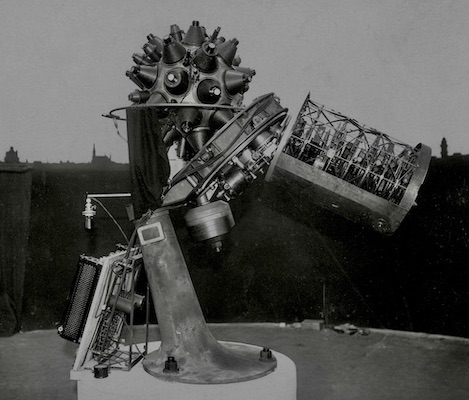

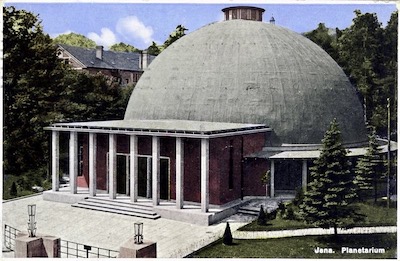

Right: Carl Zeiss Jena Astronomy Department 650 mm (25.6 inch) refracting telescope with observatory dome.

Constructed for the Berlin University Observatory at Babelsberg, completed in 1915, shown here about 1924 (84,000 bytes).

From the owner of Company Seven's viewpoint, this is what a real telescope looks like consequently, here we focus more attention on these.

Click on image to see enlarged view (129,884 bytes).

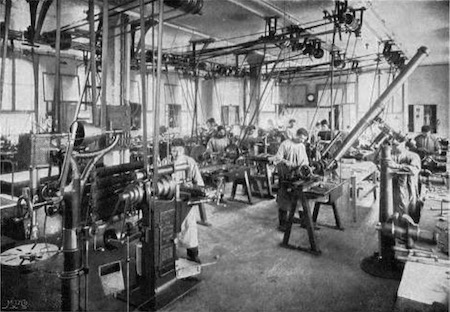

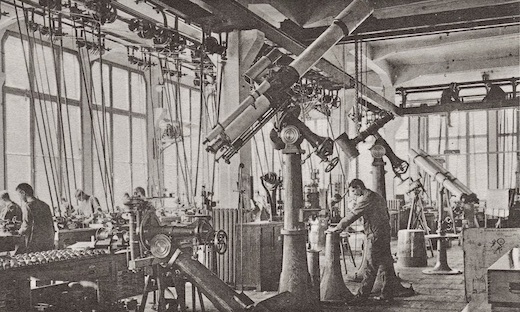

Paulÿ persuaded August Shäfer and Karl Tauchnitz to accompany him in relocating to Jena. They set up manufacturing for the mass production (large volume for the time) of lenses and mirrors, prisms, and auxiliary optics, and to produce the mechanical components. The cooperation of mathematicians and opticians already at Carl Zeiss Jena were especially beneficial to developing entirely new designs of lenses and instruments. Collaboration between the Astronomy Department and Schott AG resulted in them producing more new, or better optimized glass types.

Positive reviews of the “Jena telescopes” soon were being published. At the International Astronomical Association (Astronomische Gesellschaft) seventeenth Congress, convened on 23 September 1898 in Budapest, Dr. Max Wolf, Director of the Heidelberg Observatory, described observations with, and testing of, “an objective worked by Dr. Pauly in Jena” whose “colours are exactly comprised from the extreme red to the blue; only towards the G line the colours begin to deviate....The correction of sphericity is also small.“ Interestingly, there was no mention of Zeiss or of Schott, only a passing mention of “a new glass of Jena“ that made the new 212 mm f/21 telescope's high performance possible. Dr. Paulÿ, also attending the conference, also spoke about the manufacture of the new objective.

Some background about Achromat, Apochromat: in order to present an image that is perceptibly sharp and clear, well-representing the object of study, designers of telescopic lenses have to solve many aspects of optical physics termed “aberrations”. One of the challenges had been to produce a lens that could focus the primary colors of the spectrum (red, green and blue) to, or near to the same one image plane. The descriptive word Achromat; is derived from the Greek word for color “chrôma” and their term “alpha privatum” meaning without. Achromatic describes a lens that can focus two of the three primary colors at the same plane. With a suitably long focal ratio, on the order of f/18 or longer, the early achromat's showed little false color, at just barely perceptible levels. However, being able to focus only two colors leaves the third component color slightly out of focus. So an achromatic telescope optimized for visual uses for example would focus red and green, but leave the blue (or violet) slightly out of focus thus showing a bright object (Moon, a star) with a slight violet halo.

A higher order correction would focus all three primary colors at the same plane, and do so with so little differences or dispersion of the rays. A telescope that would show no 'false color', such as that violet or crimson halo, would show a more intense and detailed image. The system that corrects all three primary colors presents sharper, more intensly clear images than less advanced lenses. Apochromatic describes that higher order of optical performance by lenses introduced for use in microscopes of the 1850s, later for photographic cameras, and finally for premium refracting telescope objectives. Apochromat derives from the ancient term “apo,” meaning away from, hence away from color. The development of the apochromat was hindered until the late 1800s when more knowledgeable designers, improved glass types and manufacturing resources became available.

An early definition of apochromatic was that none of the light rays comprising three primary visual colors that combine to form an image, those made up of red, green and blue colors of the spectrum, spanning from Fraunhofer's C to F lines, would be out of sync from the other rays by not more than 0.05% of the focal length of the lens. Modern true apochromatic, or apo, telescopes may be corrected over wider ranges with C to G being not uncommon today. Because good refractors are so versatile and comparatively lightweight for what they show, they remain highly desired even today. Consequently there are lesser telescopes being marketed as “Apo” where in their case this is being carelessly applied. As in the days of old when good refractors were expensive, Martin cautions “good Apos even today are not cheap, while cheap Apos are not that good.”