Staticmaster Index Page

![]() Distribution

Distribution ![]() News

News ![]() Notes & Interesting Articles

Notes & Interesting Articles ![]() Pricing

Pricing ![]() Products

Products

|

|

STATICMASTER® ALPHA IONIZING BRUSH

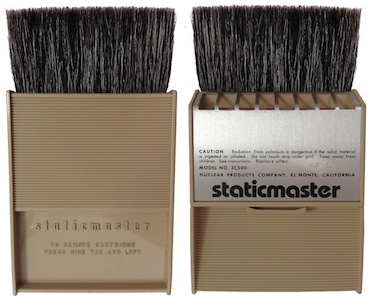

Right: NRD’s most popular consumer product - the Staticmaster® 1-inch wide brush (81,216 bytes)

Click on image to see englarged view (214,854 bytes)

Electrostatic charges attract dust, lint, and a variety of foreign particles. Especially in colder and low humidity environments one may observe how dust can not simply be blown off some surfaces since the contaminant particle may be immediately attracted back onto the lens just as a magnet attracts iron filings. The amount of moisture present in the air can affect the conductivity of insulating materials and their ability to hold a static charge too. The higher the moisture content in the air, then the more conductive a material becomes. Conversely, the dryer the air is, then the more insulative the material becomes allowing it to hold a greater charge. Although controlling humidity can be helpful, it is a very slow process and often does not afford sufficient reduction in charge to be a complete solution to the problems caused by static charging. The Staticmaster neutralizes these electrostatic charges, freeing dust or other similar particles for easy removal with the soft brush incorporated in the ferrule.

A negatively charged surface can be neutralized by positively charged ions (an atom minus one electron). Similarly, a positively charged surface can be neutralized by negative ions (an atom with an extra electron). Staticmaster’s Polonium 210 element emits alpha particles (positively charged Helium atoms) from its nucleus that collide with molecules of air, thereby creating a supply of oxygen and nitrogen ions sufficient to neutralize both positive and negative static charges. The emitted Helium ion has sufficient energy to travel about three centimeters through the air. As the Helium ion travels it strips electrons from surrounding air molecules. Each gas molecule that loses an electron becomes a positive ion. The free electron quickly attaches to another gas molecule and it becomes a negative ion. So, each alpha particle that is emitted always creates one positive and one negative ion. Hence, alpha ionizers produce an intrinsically balanced output.

Polonium was first extracted from pitchblende in 1898 by physicists Pierre Curie and Marie Curie working at their laboratory in the Ecole de Physique et de Chimie Industrielle in Paris. It was they who named the newly discovered element after Marie’s homeland, Poland. Polonium like many other elements along this line, is very toxic and rare compared to radioactive uranium and radium that are far more common. For safety the Polonium 210 is sandwiched between layers of gold, nickel and silver that are each so thin that the layers do not block the emission of Alpha particles; this is explained in good detail and illustrated in the NRD article “Alpha Ionization Innovative Solutions for Static Control”, available at our Notes & Interesting Articles section. And the element is protected by a protruding metal grill.

Every alpha ionizer source provided in the Staticmaster incorporate only a few microcuries of Polonium 210 material, still to obtain a license to manufacture and distribute these devices the design had to pass a safety analysis and battery of tests mandated by state and federal agencies, and defined by ANSI/ISO standards. Each element is leak tested prior to shipment. The quality assurance program is in place during the manufacturing processes, and these are reviewed and audited to assure compliance. It is completely safe to handle this alpha source since the particles can not pass through a sheet of paper, or through human skin. These have now been in production for over 60 years, and during that time the only instances of contamination were when the integrity of an ionizer was compromised by tampering or by physical abuse such as cutting into it.

The half-life of the encapsulated radioactive Polonium 210 material is 138.4 days, so about (14) months since manufacture have elapsed the radioactive activity of the Polonium has reduced to about 12.5% of its original level. One year after production it retains 17% of it’s original level of activity, and so the manufacturer suggests this is when the cartridge should be replaced in order to maintain optimal static control of your process.

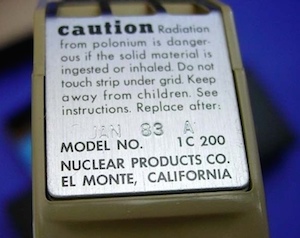

Left: the metal label plate of a Staticmaster® one inch brush. Note the stamped Polonium 210 expiration date (35,746 bytes).

Click on image to see enlarged view (88,866 bytes)

In addition to the practical considerations there is a Federal regulatory body that governs the manufacture and distribution of these devices that requires all such alpha products be inspected at intervals of thirteen months after manufacture. By returning the Polonium Cartridge the required testing can be done on our customer’s behalf.

It is a simple matter for the user to remove the encapsulated Polonium module from the brush assembly and then return it for safe disposal at the factory. Replacement modules can be ordered and easily installed by the user. Regardless of the cartridge half life status, given reasonable care the Staticmaster remains useful as a brush for many many decades to come.

Material Safety Data Sheet (MSDS) Exclusion Statement: the Staticmaster® products are exempt from having to be supported by a Material Safety Data Sheet (MSDS) in the USA. The exclusion is set forth in The United States Code of Federal Regulations, specifically in Title 29 CFR §1910.1200 Hazard Communication, Section 6, (at

Note this applies solely to the United States, you should refer to laws in countries outside the USA prior to ordering or using Staticmaster® products.

Right: the Staticmaster 3 inch brush shown ready for use and another with its bristle section retracted into the ferrule, alongside the 1 inch models (81,216 bytes).

Left: Staticmaster 3 inch brush shown with brush fully extended. In the collection of Company Seven (51,277 bytes).

When the relative humidity is very low then the static voltages may be regenerated by the friction of the brush moving along the surface even though the surface may appear to be effectively cleaned. This can be overcome by again passing the part of the brush housing the encapsulated Polonium 210 over the object without having the soft brush make contact. To obtain better static neutralizing performance the 3 inch brush design provides you may retract the soft brush into its stored position thus more easily bringing the Polonium 210 closer to the surface. One or two passes should suffice. Added benefits of the bristles being retractable into the housing include allowing better protection and more compact stowage, and a capability for the user to stiffen the bristles (for cleaning particles out of fine records grooves for example) by retracting their tips closer to the ferrule.

Avoid having to clean oils from the brush bristles. Do not touch the brush with your bare hands. and whenever practical wash hands with soap and water before cleaning a surface. Store the Staticmaster in its carton or another suitable sealed container so that it is protected from contamination and from crushing damage, and so that the bristles are not under pressure or being bent.

Cleaning the Staticmaster® it may be possible to blow particles off the brush by employing a bulb aspirator, or by blowing the bristles with regulated compressed air. If the brush has swept across areas contaminated with oily contaminants, including eyelash oils or fingerprints for example, then it will become necessary to clean the brush bristles with mild detergent or alcohol. If using a detergent insure it is either an approved lens cleaning detergent solution, do not use other harsh cleaning solvents and do not use acetone. We prefer prefer to use alcohol; simply dip the brush in and out of a small cup of alcohol and gently wipe it dry with a soft cloth. Do not compress or pull on the brush bristles.

The Alpha ionizer component should never be cleaned using any type of solvent or aqueous solution. If dust or dirt has settled in your device, it can be blown off using clean and dry compressed air. If using compressed air is not sufficient to clean the debris from the device, then the brush should be returned for evaluation.

Features of the Staticmaster®:

* Specifications are subject to change without notice.

FURTHER READING

“(6) This section does not apply to:” … “(v) Articles (as that term is defined in paragraph (c) of this section)”. “(c) Definitions. Article means a manufactured item other than a fluid or particle: (i) which is formed to a specific shape or design during manufacture; (ii) which has end use function(s) dependent in whole or in part upon its shape or design during end use; and (iii) which under normal conditions of use does not release more than very small quantities, e.g., minute or trace amounts of a hazardous chemical (as determined under paragraph (d) of this section), and does not pose a physical hazard or health risk to employees..”

NRD, the manufacturer of the Staticmaster® line of products, will not issue MSDS for the explicit reason stated above. It is their position that to do so would mislead customers, implying a hazard which does not exist. All required instructions are included with each Staticmaster shipment. Furthermore, the US OSHA has prepared regulations regarding the use of radioactive materials in industrial environments (29 CFR 1910 referenced above) that are essentially a restatement of US NRC regulations regarding such materials. The OSHA regulations specifically state that individuals using radioactive materials under the terms of a valid NRC or Agreement State Program License are exempt from OSHA regulations with regard to the use of these nuclear static eliminators. However, the end user has the responsibility to use the devices in accordance with the instruction sheets provided with the devices.

Note the protective metal grills on the brushes; the Polonium 210 capsule is affixed to the wall just behind the protective grill. Brushes in the collection of Company Seven.

Click on image to see enlarged view (186,068 bytes)

For maximum effectiveness pass the open grid area of the Staticmaster so that the Polonium 210 element is about one inch from the surface to be neutralized. No direct contact of the brush to the surface being treated is necessary for this to work. Keep the target of this treatment isolated from any source of electrostatic charges since is it possibly to recharge a surface by means of capacitance, that is where the charge migrates from one surface to another then back again.

For maximum effectiveness pass the open grid area of the Staticmaster so that the Polonium 210 element is about one inch from the surface to be neutralized. No direct contact of the brush to the surface being treated is necessary for this to work. Keep the target of this treatment isolated from any source of electrostatic charges since is it possibly to recharge a surface by means of capacitance, that is where the charge migrates from one surface to another then back again.

Click on image to see enlarged view (126,108 bytes).

STATICMASTER® 1 INCH BRUSH SPECIFICATIONS

Brush Bristle Section Length:

1 inch (25 mm)

Brush Bristle Section Width:

1 inch (25 mm)

Bristle Retracts:

No

Brush Connectors:

No

Brush Overall Length:

5 inches / 126 mm

Brush Overall Width:

1.16 inches / 29.5 mm

Weight

0.5 oz. / 15 g

STATICMASTER® 3 INCH BRUSH SPECIFICATIONS

Brush Bristle Section Length:

1.5 inch / 38 mm

Brush Bristle Section Width:

2.4 inch / 60.9 mm

Bristle Retracts:

Yes

Brush Connectors:

Yes (optional)

Brush Stored Overall Length:

3.7 inches / 94.7 mm

Brush Overall Width:

2.8 inches / 71 mm

Weight

0.5 oz. / 38 g

![]() Alpha Ionization Innovative Solutions for Static Control. The complete three page illustrated document provided as an Adobe .pdf file (170,806 bytes).

Alpha Ionization Innovative Solutions for Static Control. The complete three page illustrated document provided as an Adobe .pdf file (170,806 bytes).

Publication content copyright 2004 by NRD.

![]()

Contents Copyright 1998-2014 Company Seven All Rights Reserved