Above: NRD's most popular consumer product - the Staticmaster® one inch wide brush (81,216 bytes)

Click on image to see enlarged view (214,854 bytes)

Complimenting Company Seven for yet another journalistic coup, we were advised:

"Yours must certainly be the most definitive and comprehensively researched article ever hosted

about old products that hardly anybody, likely including NRD, appreciate or care about anymore."

NRD STATICMASTER® STATIC CONTROL PRODUCTS INTRODUCTION

NRD LLC, currently owned by automotive systems and components manufacturer Mark IV Industries Inc., is the world’s largest and most experienced manufacturer of ionization sources for the home safety and industrial passive ionization and static control markets. NRD is an innovator in technology and products using Alpha and Beta emitters in encapsulated metallic foil. Their proprietary technology is used in a wide range of products and industries including industrial static eliminators, analytical equipment, gas chromatographs, smoke detectors, and explosives detectors. They remain a specialty source for Electron Capture Detector (ECD) and Ion Mobility Spectrometry (IMS) devices, and in addition they manufacture specialty ionizers for the auto body collision industry and the photographic market. The specially designed equipment and processes, along with a comprehensive quality assurance program (that must comply with Federal regulations), ensure these products meet the highest practical quality standards set by the US Nuclear Regulatory Commission.

NRD LLC, currently owned by automotive systems and components manufacturer Mark IV Industries Inc., is the world’s largest and most experienced manufacturer of ionization sources for the home safety and industrial passive ionization and static control markets. NRD is an innovator in technology and products using Alpha and Beta emitters in encapsulated metallic foil. Their proprietary technology is used in a wide range of products and industries including industrial static eliminators, analytical equipment, gas chromatographs, smoke detectors, and explosives detectors. They remain a specialty source for Electron Capture Detector (ECD) and Ion Mobility Spectrometry (IMS) devices, and in addition they manufacture specialty ionizers for the auto body collision industry and the photographic market. The specially designed equipment and processes, along with a comprehensive quality assurance program (that must comply with Federal regulations), ensure these products meet the highest practical quality standards set by the US Nuclear Regulatory Commission.

Several of Company Seven’s founders became familiar with NRD in the late 1970’s through their use of Staticmaster ionizing and electronic static control products. The Staticmaster® brushes which have been used for decades in the audio, optics, photography and film industries have been gaining acceptance in the computer and electronics manufacturing and maintenance industries as well. For decades since Company Seven has recommended these brushes to our customers as an essential component of any well equipped telescope or camera (DSLR or film) cleaning kit.

While some of us took some interest in cataloging Staticmaster information, this article came about from our fundamental desire to 1. know well what we are using and talking about, 2. inform our own customers, and 3. while making for interesting reading at company7.com. While the antique brushes featured here are somewhat rare, we do not think of them as collectible or particularly valuable. Maybe more people in the future may better appreciate their history, particularly in context of their times, their places in the history of film photography and of audio recording and playback. Maybe some of you will offer your old brush to help us fill out our exhibit?

Company Early History:

The “Staticmaster” static control product incorporates a Camel hair bristle brush mated to a thin film(s) of an encapsulated radioactive metal product that emits alpha particles. The alpha emitter is Polonium-210, a short-lived highly radioactive silvery metal product that occurs naturally in small amounts, but for industrial uses is manufactured in a nuclear reactor. Polonium-210 was discovered in July 1898 by Maria Salomea Skłodowska-Curie (Marie Curie) and husband Pierre Curie, and was named after her native Poland.

The “Staticmaster” static control product incorporates a Camel hair bristle brush mated to a thin film(s) of an encapsulated radioactive metal product that emits alpha particles. The alpha emitter is Polonium-210, a short-lived highly radioactive silvery metal product that occurs naturally in small amounts, but for industrial uses is manufactured in a nuclear reactor. Polonium-210 was discovered in July 1898 by Maria Salomea Skłodowska-Curie (Marie Curie) and husband Pierre Curie, and was named after her native Poland.

The concept behind the Staticmaster brush seems to have originated with the U.S. Patent 2479882 titled “RADIOACTIVE METAL PRODUCTS AND METHOD FOR MANUFACTURING” by Clarence W. Wallhausen and Harry H. Dooley, Morristown, and Clayton 0. Carroll, Madison, N. J., assignors to United States Radium Corporation, New York, N. Y., a corporation of Delaware. The application was filed on 14 March 1946 and granted on 23 August 1949. The encapsulated Polonium-210 was not manufactured at Nuclear Products Company, but were contracted and produced at the U.S. Radium Corporation facilities; more about this relationship follows later in this article.

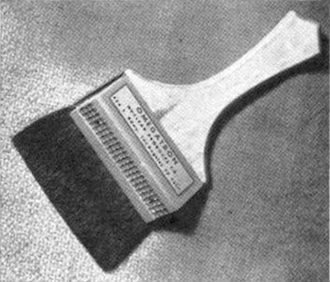

Right: the OMEGATRON labeled 3-inch brush that appeared in new product announcements of several magazines in 1949 (53,732 bytes). From the archives of Company Seven.

Mouse-over the image to see an early 1951 production 3-inch brush, bearing the STATIC-MASTER label, in our collection (29,549 bytes).

Company Seven’s archives include literature and a collection of Nuclear Products Company Staticmaster anti-static brushes with their original packaging and documents. From our archives Company Seven can date Nuclear Products Company back to the Spring of 1949. By the Summer of 1949 the three inch wide brush, possibly a prototype then bearing the label “OMEGATRON”, appeared in the new products announcements section of several popular audio industry and photography magazines. Their address then was 424 So. Broadway, Los Angeles 13, California; the ten-story office building, still known as the Judson C. Rives Building, was completed in 1906 and advertised as the first commercial high-rise in Los Angeles historic downtown area.

The earliest known advertisement specifically authored by Nuclear Products Co. appeared in a monthly trade magazine issue dated July 1949. This depicts a three-inch wide brush, with the grilled ferrule, and bearing the logo “OMEGATRON”; this is the brush shown above at right. While the first advertisements show the Omegatron-branded brush, we have found no evidence that any brushes were actually sold bearing that Omegatron tradename. Instead, by the time their first ads appeared then they had changed the product name to “STATICMASTER”. The images of the brush in the advertisements appearing in those magazine issues between July and September 1949 are of the same three-inch brush, judging by the grain in the handle, with its grilled ferrule and label showing though the lettering is blurred and indistinct in their paid advertisement commencing October. That same month, on 27 October the Staticmaster trademark registration was formalized. Some later Staticmaster literature mentions “we have been manufacturing STATICMASTER brushes since 1950”.

By the Summer of 1950 Nuclear Products Company had moved to 2150 Newport Boulevard, Costa Mesa, California, and this is the address on the brushes and in their literature accompanying the brushes. This commercial lot still houses one of the oldest home structures in the community, even though some of the land and buildings that made up the parcel in the early 1950’s has since been subdivided and remain commercial.

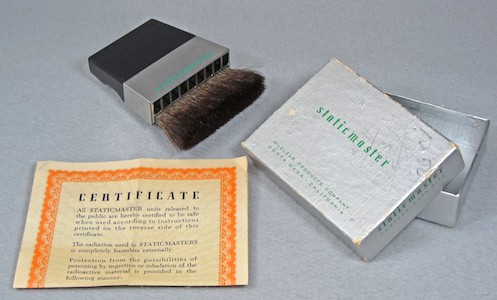

Left: 1951 production Staticmaster brush with red packing carton labeled Static Master Jr. Note by this time production had changed from dark to natural wood finished handle (38,408 bytes). In the collection of Company Seven.

Click on image to see enlarged view (129,052 bytes).

Prior to the development of these brushes, people employed fine brushes and compressed air (a bulb aspirator for example) to brush and blow dust and dirt off sensitive materials surfaces. But particularly when working on synthetic materials (vinyl, nitro cellulose films, magnetic tape, etc.) static attraction makes it difficult to keep the surface clear of fine particles. Static will not only cause the particle would be attracted back onto the surface being cleaned but can actually attract contaminants to cling to the surface, resembling how a magnet works on iron filings. Static attraction is particularly troublesome in cold and or dry environments. Passing the Polonium-210 cartridge near that surface neutralizes the static attraction, and that prevents attracting that and other contaminants back onto the surface. Because of their critical distinction from standard bristle brushes, the Staticmaster were initially marketed to facilitate the removal of dust and to neutralize static build up for the audio and photography industries with advertisements featuring the slogan:

“Science Stops Dust”

While the first publicized brush was the 3-inch wide sample one shown above at right with an angled slotted grill, and these may have been the earliest production versions of the Staticmaster brushes, there was also the 1-inch wide version. To the present day Staticmasters are made in both the 1-inch, and in 3-inch wide versions.

At a glance the first production versions resemble a standard painting bristle brush with a conventionally styled wooden handle finished in dark tone, but with a stamped steel ferrule made to incorporate the strip of an encapsulated Polonium-210 (Po210) Alpha radiation source. The source is protected behind a protective metal grid. The production brushes ferrule design differs from the angled prototype; production versions incorporate an arrangement with a checkerboard-pattern grated grill arranged about orthogonally relative to the brush bristles.

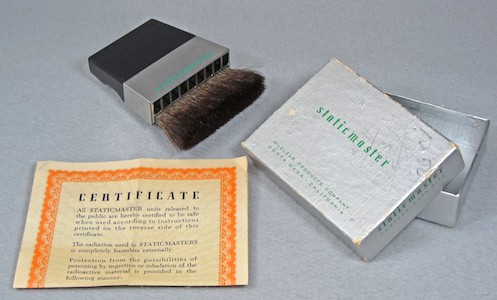

Each brush was provided in a cardboard carton for convenient storage. For example, cartons of the 1-inch brushes produced in 1951 were a dark red covered labeled “Static Master Jr.“, the brushes made bear an expiration label. Those dated July 1952 and later (made in 1951) transitioned from the dark wood to a clear wood finish, that likely made them easier to see in the red or yellow illumination of a photographic darkroom. By Spring 1952 the 1-inch brush carton (made at least as far back as March, and since then) were labeled “STATICMASTER“ as were the larger 3-inch brush cartons.

Right: late 1951 production brush with red packing carton labeled STATICMASTER, and instruction/certificate sheet (31,318 bytes). By this time the packing carton color tone had also been changed to darker red than those of the originals. In the collection of Company Seven.

Click on image to see enlarged view (93,238 bytes).

The Staticmaster 1-inch wide brushes were sold new through the 1950’s for between $4.25 to $4.95, while the 3-inch models sold for about $12.50 respectively. Note this was in an era where consumer prices and salaries on the whole remained pretty stable between World War II towards the end of the Vietnam war era; why everybody in economics seems to think annual inflation is a good thing must be either or both too young or too dumb to recall the tranquility of the previous eras. Staticmaster brushes prices increased over the 1970s, remaining about the same through the 1990s.

Since the effective life of the Polonium-210 capsule is limited owing to its natural decay process, a new replacement capsule (later termed cartridge) could be purchased from the Nuclear Products Company and installed by the user. The price of the replacement cartridge included delivery by mail to within the U.S.A. Ideally, the old capsule would be returned to the company or to another authorized facility for proper recycling and disposal.

Products Evolution:

The first production Nuclear Products Inc. brush that we know made it to market is a 3-inch model. This first generation production brush resembles the OMEGATRON preproduction prototype, the 3-inch brush shown in their early advertisements, with the grilled stamped stainless steel ferrule housing the Polonium-210 foil appearing nearly identical.

The earliest example of the 3-inch brush in Company Seven's exhibit was of the appearance that were produced no earlier than June, in 1950. We deduce this from the accompanying instruction sheet that mentions Costa Mesa as their office location, so this means these would have been produced no earlier than summer of 1950. Company Seven has other documentation to indicate these 3-inch brushes were in production, in this form, by July 1950.

Left: very early production “STATIC-MASTER” labeled 3-inch brush with carton and instruction sheet, from 1950 (61,771 bytes).

Exhibited at Company Seven through courtesy of W. Wright.

Click on image to see enlarged view (224,727 bytes).

This early brush resembles the OMEGATRON brush, but instead of the crowned wood handle tip of the prototype the production brushes have a single rounded peaked wood handle.

These very early production brushes incorporate a wood handle that was likely converted from a conventional production paint brush, the ferrule being attached to the wood handle cut from a production paint brush. Our earliest 3-inch brush bears stamped information on the handle showing this component was manufactured by Delta Brush Mfg. Corp., of New York whose trademark registration went back to January 1948, though their history predates that to at least October 1946:

3" DELTA 217 U.S.A. SET IN RUBBER

The ferrule of these earliest 3-inch brushes bear a rectangular stick-on decal with “STATIC-MASTER” branding, the accompanying instruction sheet too bears the STATIC-MASTER branding. The label has bold red STATIC-MASTER lettering, with black “NUCLEAR PRODUCTS CO, Los Angeles, Calif USA” against a red-bordered yellow background. There was no warning label or other indicator on the back of the brush head or on the front of the ferrule grill area. These were provided in a dark red carton, labeled with Nuclear Products Co and STATIC-MASTER, this lettering is in silver.

By the middle of 1951 the first caution sticker appears on the brush ferrule underside panel. The original stick-on yellow warning label read “CAUTION Do not touch radio active strip (under grid). Keep brush away from children. See Instructions. This STATIC-MASTER guaranteed until ____”, the expiration date being stamped by an ink date stamper.

As on the 3-inch brush shown above at left, this very early mid 1950 handle by DELTA has a dark brown thick gloss finish. Later production 1 and 3-inch brushes have a slightly different medium reddish-brown stained finish, one of these brushes is shown below at right. These later wood-handled brushes lack the DELTA labeling, or any information at all about the source of the wood handle.

The oldest Staticmaster 1-inch brush in Company Seven's exhibit is an original style wood-handled model from Spring 1951 production shown below at right. These have a dark brown wood finished handle with a more steeply peaked top end. The 1-inch model bears a yellow on black stick-on paper label affixed to the top of the ferrule reading “STATIC-MASTER, NUCLEAR PRODUCTS CO., COSTA MESA, CALIFORNIA U.S.A.”.

No later than November of 1951 the wood handle finish transitioned from brown to a more natural pine wood finish. We speculate this may have happened because of a change of sourcing, or more likely the fact that brown brushes are harder to find than the lighter wood handle under the dark red lamp in a film processing darkroom.

By 1952 the brush ferrule underside warning label changed to a blue-green on white warning sticker reading “CAUTION Do not touch radioactive strip (under grid). Keep away from children. See instructions NUCLEAR PRODUCTS CO. COSTA MESA, CALIF. This STATIC-MASTER guaranteed until xxx 195x” with the month and year 1950, 1951, 1952, or 1953 rubber stamped onto the label.

Right: early production 1-inch brushes from mid 1951 (dark handle), and early 1952 (37,986 bytes), in the collection of Company Seven.

Click on image to see enlarged view (121,287 bytes).

By then their 3-inch brush bears similar labels with the STATIC-MASTER brand label is scaled for the wider brush ferrule but with an identical warning and expiration date sticker as that affixed to their 1-inch brushes. In the Summer of 1952 the top label sticker was changed so that it reads simply STATICMASTER, as does the lid of the red packing carton; the set then selling for $4.95.

However, as late as that Fall 1952 the brand was still being advertised in publications as “STATIC-master”. Later literature, such as our Christmas 1956 ad copied below at right on this page, represents the product line as STATIC-MASTERS. Though the labeling of production brushes and cartons were initially OMEGATRON, then STATIC-MASTER and by 1952 STATICMASTER, we wonder why the product marketing brand names changed, at least four times (OMEGATRON, to STATICMASTER, then STATIC-master, then STATIC-MASTERS), between 1949 and 1956 before settling back to Staticmaster as the final trademarked name? Below we come up with at lest one theory about why one of the name changes may have come about.

The change of labeling appears to have had something to do with a Federal Trade Commission Decision dated 24 May 1956 published in their “Findings, Orders and Stipulations”, Volume 52, page 1785 where Kenneth A. Smith, identified as:

an individual operating under his own name with his principal office and place of business at Burbank, Calif. engaged in offering for sale and selling in commerce, a device designated “Omegatron” consisting of a strip of radioactive polonium gold foil behind a protective shield and grid mounted on a camel's hair paint brush, for use in removing static electricity, dust and lint from phonograph records and transcriptions.

Kenneth A. Smith entered into an agreement that he will cease and desist from offering for sale, selling or distributing in commerce, the device designated “Omegatron” or any other device containing the element polonium as an active ingredient, unless adequate cautionary or warning notices are c1early and conspicuously impressed or imprinted upon said device or permanently attached thereto, indicating possible harmful effects of ingesting or inhaling polonium and directing the user not to touch the polonium element and to keep the device away from children; provided, however, that such warning or cautionary notices may be condensed if they clearly refer to and are amplified by adequate directions for use separately printed and enclosed in the carton or permanent container in which said device is shipped and kept.

This is helpful to our research since it also provides a name, Kenneth A. Smith, associated with the product at the time and we link him back to Salina, Kansas. But it is also confusing since the use of the Omegatron trade name had long been discontinued. Furthermore, the labels of the Staticmaster brushes we exhibit that were made since at least Spring 1951 incorporate the warning label, and were accompanied with a printed instruction sheet too, so could it be the FTC process required five years or so before a decision was published? Could it be the Omegatron name was dropped to distance it from any investigation that may have already commenced? It will take more homework to find that out.

About the year after the original style brushes were introduced and while still based at Costa Mesa, the Nuclear Products Company introduced their redesigned Staticmaster brush. The first was a 3-inch wide version (shown below at right) resembling the 1-inch brush but wider of course. This second generation 3-inch model appears distinct and more like a custom designed brush, with a black painted wide wooden handle but with an angular grilled ferrule incorporating one long strip of the Polonium-210. These bore a stick-on paper label with green trim and with the expiration date stamped on it, similar to but wider than those applied to the 1-inch model. The carton of these larger 3-inch brushes were labeled Professional Size model. Each was accompanied by a certificate, guarantee and information about replacing the Polonium capsule. Printing of the instructions and certificate documents was contracted and the earliest certificates we have that accompanied a brush were by GOES, but from the late 1950’s and into the early 1960’ the Jeffries Banknote Company of Los Angeles was printing these for NRD.

In the first months of 1953 the company relocated from Costa Mesa to 10173 East Rush Street, El Monte, California and the 1-inch wide brush acquired a new and more distinctive styling too. This second generation brush features a tapered shape with rounded corners that was to be the basis of their production models from then throughout the early 1960’s. These consist of a plastic molded body with a wide opening at the front to accept the brush and the grated housing with the encapsulated Polonium-210. The earliest of these bodies, those made from about April 1953, are of light gray with white STATICMASTER lettering across the handle. These 1-inch brushes bear a printed metal plate indicating the maker, cautions, and with the expiration date stamped on the plate. The same style metal plate was also applied to the 3-inch brushes, these were still being marketed as the Professional Size model. By the the summer of 1953 the color of the production 1-inch brush body had transitioned from gray to black, still with the white STATICMASTER lettering and with the date-stamped metal plate. Most 1-inch brushes made in 1955 bear the model designation “1S 50” while those made after August 1955 and through Spring of 1957 do not bear the model; those without the model designation bear a plate similar to those provided on the 3-inch brushes. Examples of these styles of 1-inch and 3-inch brushes and their original storage cartons too are illustrated below.

Above: Staticmaster 1-inch brushes. That below with a silver carton expired April 1955 while the one with its label showing and yellow carton expired March 1958 (48,193 bytes).

At center and right is a 3-inch Staticmaster, probably made in 1952 it’s Polonium element expired Nov. 1953 (94,062 and 47,717 bytes). All are in the collection of Company Seven’s museum and archives.

Click on images to see enlarged views (177,439 and 206,636 and 210,493 bytes).

The 3-inch brush was redesigned in 1956 to a form that resembled a stubby version of the then production 1-inch model, and with a rounded ferrule. This was the third generation of 3-inch brushes. These feature a moulded plastic body in an off-white ivory color, the earliest of these incorporating the 3T500 cartridge. In time other colors of body were sold including tan or a teal blue body incorporating the 3T125 cartridge. The earlier versions of these third generation 3-inch brushes bear labeling on the top of the ferrule in the lower case “staticmaster”, and on the line below the 3R 500 and 3T 125 brushes made since 1956 may also bear “RECORD BRUSH”; this is the labeling on the bright blue brush illustrated farther below at right in this article. This indicates how important the record cleaning market for these brushes was then. By fall of 1960 and since then too all the production 3-inch 3T 125 brushes labeling changed to simply bear the “staticmaster”.

The 3-inch brush was redesigned in 1956 to a form that resembled a stubby version of the then production 1-inch model, and with a rounded ferrule. This was the third generation of 3-inch brushes. These feature a moulded plastic body in an off-white ivory color, the earliest of these incorporating the 3T500 cartridge. In time other colors of body were sold including tan or a teal blue body incorporating the 3T125 cartridge. The earlier versions of these third generation 3-inch brushes bear labeling on the top of the ferrule in the lower case “staticmaster”, and on the line below the 3R 500 and 3T 125 brushes made since 1956 may also bear “RECORD BRUSH”; this is the labeling on the bright blue brush illustrated farther below at right in this article. This indicates how important the record cleaning market for these brushes was then. By fall of 1960 and since then too all the production 3-inch 3T 125 brushes labeling changed to simply bear the “staticmaster”.

Right: Staticmaster 3-inch brushes. The one at left is a Model 3T 125 manufactured in 1959, the other is a current production Model 3C 500 shown with its bristles fully extended from the ferrule. Note their differences of Polonium-210 strip arrangement. These are in the collection of Company Seven’s museum and archives (82,834 bytes).

Click on image to see enlarged view (214,049 bytes).

These redesigned 3-inch brushes bear their Polonium-210 expiration date printed on the inside lip of the metal cartridge. Labeling indicated the model number that referred to the brush width and the Polonium-210 ceramic micro spheres output rating in micro curies (symbol µCi, µc) and the arrangement of the Polonium-210 strip: 3T 500, 3R 500, or 3T 125 for example. The cartridge could be removed from the brush body by the user and the Polonium-210 element could be replaced by the user.

Up to 1956 the price list accompany each brush lists only two cartridges, and the appropriate refill was simple to determine since the brushes and their cartons bore no model numbers until about 1957, these were the 1-inch cartridge then selling for $2.50 and the 3-inch selling for $5.75. By 1959 the various replacement cartridges being offered included five different models listed as: 1S50 for $2.50, 1S200 priced at $3.70, the 3T125 for $4.95, 3R500 at $7.45, and 3T500 for $7.95 and these prices remained in effect throughout the production life of this style 3-inch brush; prices did not change for almost ten years! Note the replacement cartridge prices included postage for return delivery to the buyer. By as late a 1976 the prices of the complete new brushes too remained reasonable, the 3-inch model then selling for $15.00 while it’s replacement Polonium-210 cartridge alone cost $10.00. Retail prices of the brushes remained pretty consistent nationwide from 1949 well into the 1970’s, and with few increases of cost. By 1985 variations of the selling prices become apparent, for example the 1-inch brush was being sold for $9.85 at one camera store while another sold the same model brush for $14.95.

In the Spring of 1963 the design of the Staticmaster 1-inch brush body was again changed from the prior S style body to the C style, their being their third major 1-inch brush redesign. This newly styled brush was announced by June in trade magazine advertisements, and also in science and technology magazines. This new brush resembled the 1-inch brush design that remains in production through today with the tan plastic handle, but with a removable brown plastic panel and Polonium-210 cartridge, the brown being visible from the sides or from underneath. Removing the Phillips head screw that is accessed from above releases the Polonium-210 cartridge. This basic 1-inch model brush was designated the 1C 50 and sold for $4.95, with the replacement cartridge priced at $2.50. A higher output 1C 200 replacement cartridge could be ordered for $4.45. By about 1973 the brush moulded plastic handle and cartridge housing were both being made of matching tan plastic, and it is this arrangement that continues in production through today.

In the Spring of 1963 the design of the Staticmaster 1-inch brush body was again changed from the prior S style body to the C style, their being their third major 1-inch brush redesign. This newly styled brush was announced by June in trade magazine advertisements, and also in science and technology magazines. This new brush resembled the 1-inch brush design that remains in production through today with the tan plastic handle, but with a removable brown plastic panel and Polonium-210 cartridge, the brown being visible from the sides or from underneath. Removing the Phillips head screw that is accessed from above releases the Polonium-210 cartridge. This basic 1-inch model brush was designated the 1C 50 and sold for $4.95, with the replacement cartridge priced at $2.50. A higher output 1C 200 replacement cartridge could be ordered for $4.45. By about 1973 the brush moulded plastic handle and cartridge housing were both being made of matching tan plastic, and it is this arrangement that continues in production through today.

Left: newly styled 1-inch brush announcement in trade magazine advertisement from July 1963 issue of Popular Mechanics magazine.

The 3-inch brush retained the same third generation molded body and ferrule style as had been made since 1957 though colors of the body varied from ivory, teal blue - shown above right, bright blue, or tan that were made until the end of the 1960’s. By 1969 the 3-inch brush too was redesigned to a molded tan colored handle with angular edges and grilled ferrule, this being the fourth generation body and cartridge housing design and is the arrangement that remains in production with only minor changes of labeling to date. These newly restyled 3-inch brushes have an added feature not provided either the older models or with the modern 1-inch model, the 3-inch brush bristles can be retracted into the handle thus affording: 1. better protection and more compact stowage, and 2. by retracting the bristles back into the ferrule then the bristles are more compacted and are therefore stiffened to reach better into fine grooves of a record for example.

From 1958 through about 1971 the model designation for the most popular 1-inch brushes produced had been either 1S 50 (older black handle style) or 1C 50 (tan molded body) reflecting the brush width and Polonium output. By 1963 the 1C 200 cartridge became available as a refill. By 1971 one could buy either brush, the 1C 200 or the 1C 50, both appearing identical other than the imprinted model designation on the metal label plate and both with the brown cartridge housing. Eventually, certainly by late 1972, the 1C 50 was discontinued and all production 1-inch brushes made since incorporate the 1C 200 cartridge in a tan housing matching the handle color; this remains the current model configuration. The cartridges were made with color-coding of their Polonium-210 strips, 1C 200 in red while the 1C 50 were blue-green. After the transition to all 1C 200 these were made with gold foil clad Polonium-210 strips.

From 1958 through about 1971 the model designation for the most popular 1-inch brushes produced had been either 1S 50 (older black handle style) or 1C 50 (tan molded body) reflecting the brush width and Polonium output. By 1963 the 1C 200 cartridge became available as a refill. By 1971 one could buy either brush, the 1C 200 or the 1C 50, both appearing identical other than the imprinted model designation on the metal label plate and both with the brown cartridge housing. Eventually, certainly by late 1972, the 1C 50 was discontinued and all production 1-inch brushes made since incorporate the 1C 200 cartridge in a tan housing matching the handle color; this remains the current model configuration. The cartridges were made with color-coding of their Polonium-210 strips, 1C 200 in red while the 1C 50 were blue-green. After the transition to all 1C 200 these were made with gold foil clad Polonium-210 strips.

Right: assortment of three generations of Staticmaster 3-inch brush designs made, including the present style shown with brush fully extended. In the collection of Company Seven (91,961 bytes).

Click on image to see enlarged view (306,707 bytes).

The 3-inch brushes been made with cartridges that have incorporated one long Polonium-210 strip; these have borne the model designations 3R500, then 3C125, 3T125. The later production 3C500 incorporate two separate strips of Polonium-210 arranged side by side. The earlier production versions of the current style 3-inch brush bore “staticmaster 500” in the original font style on their ferrule, though in mid 1976 the company transitioned the 3-inch brush cartridge labeling to “staticmaster” in their stylized font. By 1984 this was changed to a simplified staticmaster type logo label shown at right, the latter matching the simplified “staticmaster” solid font style as has been molded into the brushes plastic handles since 1963.

Products Packaging:

The packaging provided with new Staticmaster brushes evolved over the years with some changes simply reflecting taste or marketing strategies. Some afforded practical improvements, or later in particular they reflected efforts at cost cutting. The original packing carton featured a deep red exterior (shown above left) that prominently bore the company name “Nuclear Products Co.” When the brush and handle designs were changed in the Fall of 1952 the provided carton for the 3-inch model was finished in silver that more prominently featured the Staticmaster trade name, and below that in smaller type was the company name all in green print. For the 1-inch brush Nuclear Products Co. provided a carton with a silver on black with red trim scheme through March 1955, by May 1955 this was changed to a yellow on black with red carton as shown above left of center. From about May of 1957 through 1969 the brushes were provided in a clear plastic hinged lid box, that set was packaged in a natural paper carton sleeve. Some of the early plastic cases provided with the larger 3-inch brush bore the embossed message on their lid “THE POLONIUM STRIP DOES THE TRICK”. Then through the 1970’s these were sold with an orange-red carton; neither of the latter made any mention of Nuclear Products Co.

By 1976 the carton was an even simpler but more contemporary styled black box and with the STATICMASTER trade name in silver across the top cover and on the end with the model number, but with no mention of the company name. In the Fall of 1979 the packaging changed to a carton with a dark brown wood print covering and with no labeling at all (as shown at the bottom left of this page) and with no mention of the company name, later versions have a lighter oakwood grain pattern. In the early 1990’s the brushes were furnished with a flexible plastic pouch with flap closure provided in a lightweight hangable display box. By about 2000 NRD reverted to the carton similar to the wood grain style but with a white on blue marbled pattern printed covering as shown below at right, the set provided in a lightweight hangable display box. Current production brushes include no protective storage carton whatsoever, instead the brushes are sold in a lightweight hangable display box as shown at the top of this page.

Relocation to Grand Island:

By 1975 Nuclear Radiation Development, Inc. had been acquired by Glar-Ban International, a manufacturing company based Cheektowaga, New York. In 1976 Glar-Ban and Mark IV Homes, Inc. merged and changed the name of the company to Mark IV Industries, Inc. then based in Williamsville near Buffalo, New York. NRD, LLC continued operations in El Monte, California where it had been based since 1953 through the Fall of 1989 when the company's remaining operations commenced being relocated to Grand Island, New York and the company product labeling transitioned from "NUCLEAR PRODUCTS CO." to "NRD, INC".

Our database records no Staticmaster brushes labeled with December 1990 or January 1991, at least not yet. Interestingly enough, we do have 3-inch 3C500 brushes stamped as late as February and March of 1991 bearing the El Monte, California labeling; this in itself does not necessarily mean these were made in El Monte since their components could have been leftover inventory assembled after being transferred to Grand Island. Regardless, it appears however that production was well underway in Grand Island, New York by 18 months prior to April 1991, these were produced by October of 1989, and those brushes made since to this day bear the New York address.

For some time after the relocation their outer packing and color-illustrated instruction booklets provided with each brush were old stock from California. Some instruction booklets bear a sticker over the old address listing the New York address and "NRD INC. A SUBSIDIARY OF MARK IV INDUSTRIES INC." contact information. For some months after, at least through the Summer of 1991, the relocated NRD, Inc. continued to distribute brushes in their old stock of outer packing cartons; those of the 1 and 3-inch brushes bear a brush illustration still with the labeling "NUCLEAR PRODUCTS CO." and "EL MONTE, CALIFORNIA".

Staticmaster® and Polonium:

Polonium was first extracted from pitchblende in 1898 by physicists Pierre Curie and Marie Curie working at their laboratory in the Ecole de Physique et de Chimie Industrielle in Paris. It was they who named the newly discovered element after Marie’s homeland, Poland. Polonium like many other elements along this line, is very toxic and rare compared to radioactive uranium and radium that are far more common. For safety the Polonium-210 is sandwiched between layers of gold, nickel and silver that are each so thin that the layers do not block the emission of Alpha particles; this is explained in good detail and illustrated in the NRD article “Alpha Ionization Innovative Solutions for Static Control”, available at our Notes & Interesting Articles section.

Right: left to right are 1954, 1953 (gray), and 1957 production Staticmaster brushes with a mid 1950’s carton (38,408 bytes).

In the collection of Company Seven.

Click on image to see enlarged view (99,226 bytes).

We at Company Seven were particularly surprised to learn about the early consumer uses of this product since some of us had known Polonium was among those materials developed for the Manhattan Project. It was a Polonium-based modulated neutron initiator that was used to start the chain reactions in the first atomic bombs. Polonium and beryllium were key ingredients of the implosion-type nuclear ’urchin’ detonator at the center of the bomb’s spherical plutonium pit; it was this type of bomb, nicknamed Fat Man, that was dropped on Nagasaki in 1945. The role of Polonium in these weapons remained classified until well into the 1960’s.

The United States Nuclear Regulatory Commission regulates these devices. with no more than 500 µCi (19 MBq) of (sealed) 210Po per unit can be bought in any amount under a “general license”,[74] which means that a buyer need not be registered by any authorities.

The half-life of the encapsulated radioactive Polonium-210 material is 138.4 days, so about (14) months since manufacture have elapsed the radioactive activity of the Polonium-210 has reduced to about 12.5% of its original level. One year after production it retains 17% of its original level of activity, and so the manufacturer suggests this is when the cartridge should be replaced in order to maintain optimal static control of your process. So a brush that bears an expiration date of July 2014 for example contains a cartridge that was made one year before then. After its effectiveness has diminished, this cartridge can be removed from the Staticmaster brush ferrule by the owner and returned to NRD for safe disposal. A replacement cartridge can be ordered to regain the effectiveness of the Staticmaster.

The Staticmaster is not a toy!

Do not leave these out for children to play with. Nor should you store a Staticmaster near your skin, such as in your shirt or pants pocket, when you are not using it.

Do not leave these out for children to play with. Nor should you store a Staticmaster near your skin, such as in your shirt or pants pocket, when you are not using it.

Right: Staticmaster 1-inch brush and marbled blue storage carton. Note radiation burn pattern, accumulated over years of updated Polonium-210 cartridges resting inside the lid. The pattern corresponds to that of the metal grill over the Polonium-210. This brush owned by the owner of Company Seven - coincidentally who made no children (98,265 bytes).

Click on images to see enlarged view (161,764 bytes).

In order to protect the brush do not contaminate it by touching it with your fingers or to surfaces that have been contaminated by oils. Fingers too can emit oils and enzymes that may contaminate the brush, after then anything else you try to clean with a dirty brush will in turn be contaminated. So it is good practice to wash your hands before attempting work on optics, film slides or negatives, etc., even better to wear disposable or clean gloves too while working on sensitive items. If the brush becomes contaminated then the bristles with an alcohol or mild clear soap solution, do so gently and without pulling the bristles.

When not in use store the Staticmaster in its provided carton or in some other hard shell container that does not put pressure on the flexible brush bristles.

Sidenotes about TMI (not that TMI), Litvinenko, Arafat, and Polonium:

When the Staticmaster products first came onto the market in 1949 the term “nuclear” promised a wondrous future of great advances and a better life however over the recent decades there have occurred some events that took off some of the luster. Though these events had nothing to do directly with the Staticmaster products, the events likely impacted some people’s perception of nuclear technologies:

- The Three Mile Island (TMI) nuclear accident that occurred on 28 March 28 1979 was the worst accident in U.S. commercial nuclear power plant history up to that time. The incident raised public awareness about issues pertaining to nuclear safety and radioactive materials handling, and helped to coalesce some public groups into lobbying against nuclear power. This incident and the types of materials employed in the nuclear reactors have nothing to do with short-lived radioactive materials that are vital components of many consumer products including smoke detectors, and Staticmaster® products.

- In November 2006 the former KGB agent and later Kremlin whistleblower Alexander Litvinenko was poisoned and later died apparently from drinking tea laced with the radioactive element Polonium-210. Polonium’s alpha particles do not travel far and can be blocked by materials as simple as a sheet of paper. But if ingested in sufficient quantity then it is extremely dangerous to humans as the radiation will cause cellular damage and ultimately death. Experts concluded Litvinenko ingested less than one millionth of a gram*, still more than enough Polonium-210 to cause the acute radiation sickness that killed him. The police consider his death to have been murder, although the London coroner’s inquest remains open.

- Palestinian leader Yasser Arafat died in November 2004, but in 2012 his body was exhumed in an effort to determine whether his death was caused by Polonium-210 poisoning. Whether or not this was true, the story brought Polonium-210 back into the news.

* The Staticmaster product contains a fraction of this amount of Polonium-210, and so even if accidentally ingested would likely not result in death. As explained by the US Nuclear Regulatory Commission “BACKGROUNDER” publication ML063490067.pdf: “the chance of someone getting hold of a lethal dose of Polonium-210 is very small. Both the form and amount of radiation in exempt sources mean they would pose no health problem if ingested. It would take tens of thousands of these sources to make a fatal dose. It would be extremely difficult - requiring sophisticated lab work - to extract the Polonium-210 and render it in a form that could be used to harm someone. It would also be hazardous and expensive, and would violate NRC regulations.” This document is hosted by Company Seven at our Staticmaster Notes & Interesting Articles page.

Regardless, the word “nuclear” became a highly sensitizing term in marketing. We observed the word disappear from the labeling of many products and from the memory of many.

The Path To NRD:

When the author of this article interviewed some people who work at NRD, Inc. to ask where the company originated, none could recall much about that. None could tell me what the abbreviation NRD might have originally represented, other than the first word may have been nuclear. My search of Patent records found US3818545 A indicated this was Nuclear Radiation Development, Inc. Researching the records I came to better comprehend where the name NRD originated, and why one does not see its full name very often: in no small measure it is likely because of its relationship to the U.S. Radium Corporation.

NRD’s history goes back to 1914 when the Radium Luminous Material Corporation was established by Dr. Sabin Arnold von Sochocky and Dr. George S. Willis in New York City. In August 1921 the company was renamed the United States Radium Corporation. The company prospered but would become infamous for its innovative glow-in-the-dark (luminescent) paint, marketed from 1917 to 1938 under the trade name “UNDARK”. Undark was a mixture of radium and zinc sulfide where the radiation caused the sulfide to fluoresce green. This orange-toned paint was applied to watches, dials, and to other equipment that needed to be read in low light conditions. Unfortunately, it was not until 1924 when the risks of working with these materials were established by Dr. H.S. Martland. By then the casual exposure had led to many needless employee illnesses and deaths, most prominently were those of the “Radium Girls”. The company co-founder, Dr. von Sochocky, died in November 1928 also of aplastic anemia resulting from exposure to the radioactive materials.

The original Staticmaster brush products came onto the market in 1949, just as the U.S. Patent 2479882 was granted to the United States Radium Corporation. Given the complexity and high technology requirements to produce and then encapsulate new Polonium-210, it seemed logical the capsules (if not the entire brushes) were manufactured at some facility other than the addresses listed for Nuclear Products Company. This theory was confirmed by meeting notes, a copy is in our archives, convened on 17 December 1957 between U.S. Government Atomic Energy Commission staff and U.S. Radium Corp. Here personnel relate how the question arose about what were the melting points of the foil and of the Polonium? This might have been in the context of assessing the risks of Staticmasters when exposed to fire. The notes indicate “Mr. Dooley agreed that U.S. Radium should make such tests since they were the manufacturers of the foil.”

U.S. Radium ceased radium processing altogether in 1968 spinning off the luminescent paint operations as Nuclear Radiation Development Corporation, based in Grand Island, New York. The U.S. Radium factory facilities in Orange City, New Jersey remained so highly contaminated by radioactive materials, that it was designated by the U.S. Environmental Protection Agency (yeah, among those agencies that some Republican candidates for office promise to close) to be a Superfund trust site CERCLA No. NJD980654172 that was cleaned up under administration of the US EPA between 1997 and 2005.

The above facts raise questions about whether or not the Nuclear Products Co. or its founders were somehow involved with U.S. Radium Corporation? Or was Nuclear Products Company always a subsidiary, or absorbed in 1968-69 during the spinning off of Nuclear Radiation Development Corporation (NRD)?

In 1969 the Nuclear Products Company appears to have continued normal operations under NRD, with assembly and or offices remaining in El Monte, California until some twenty years later when this was relocated to Grand Island, New York. The brushes bearing Nuclear Products Co. as the maker also continue to indicate the origin as El Monte, CA. On 13 August 1984 the NRD company filed to change it’s registration to NRD, Inc., still based in New York state. On 23 December 1993 NRD, Inc. relocated their corporation to Delaware. On 23 April 1998 NRD, Inc. filed to change its corporate structure and effective 10 March 1999 operated as NRD, LLC (limited liability corporation) while the former NRD Inc. was formally dissolved on 11 April 2000. In 2007 NRD, LLC was acquired by Mark Iv Industries, Inc., a New York based corporation, and NRD continues operation (NRC License No. 31-28397-01G) even after a tumultuous time that included reorganization of the parent company and its subsidiaries in 2009.

But keep it in mind that there appear to have been no published instances of death or injury involving any Staticmaster product. Furthermore, these products are considered by regulators to be so safely packaged a commercial product that anyone in the US can buy and posses these products.

|

Staticmaster® Sales and Distribution:

Range of sales distribution: as mentioned above, in 1949 the Staticmaster brushes were initially advertised by the manufacturer in audio and then photography industry media. The Staticmaster brushes came to be sold at thousands of local stores that sold cameras and film, ones that sold phonograph records, and at stores that offered high fidelity recording and playback gear in the United States. You could walk into these stores and see Staticmaster brushes hanging on display in areas where accessories were featured. However, we can find no signs of these products ever having being distributed in Europe or elsewhere overseas. In fact the price sheet for replacement Polonium-210 cartridges that accompanies each brush made between approximately 1959 through about 1962 mentioned “Reactivation presently available only in the U.S.A.”; this limitation had never before appeared in the literature.

Right: Staticmaster advertisement appearing in September 1952 PHOTOGRAPHY magazine. The head design has changed since their introduction in 1949, the peaked handle is stained dark brown. The ad header refers to these as “STATIC-master” and lacks the ® registered trade name symbol suffix that would appear in later ads (81,871 bytes).

Mouse-over the image to see a later advertisement from Christmas 1956. This features a 1-inch brush bearing the electric “STATIC masters” header and describing these as “STATICMASTERS” (91,461 bytes).

Both ads are scanned from the magazines from our collection.

That limitation mentioned above about overseas sales has us speculating whether or not this may have had something to do with: 1. stricter regulation of radioactive materials for consumers overseas, 2. complexities and or costs of sending a product that is classified radioactive materials in any bulk shipping arrangements to overseas, 3. the lack of a facility overseas to facilitate return and replacement of the Polonium-210 capsules. While our recent studies of on-line Internet sites that sell new or used brushes find they remain available for sale new and used in the USA, we see no signs of new or used brushes coming up for sale in Europe for example.

Markets, marketing, and sales trends: we suspect the consumer sales of Staticmaster brushes may have peaked by about the late 1980’s or early 1990’s; up to then it had been possible to find numerous stores where the consumer could readily acquire the product. But the retail marketplace was undergoing several major revolutions:

- As manufacturers allowed the then up and coming, largely New York-based, discount mail order companies to take larger and larger slices of the photography market since the 1980’s in particular, then we observed a decline in the numbers of the better photography stores. It was becoming more difficult to find a store locally that would sell top-of-the-line photographic cameras and a lenses, those products that were likely also attract the more astute customer who would be a candidate to casually buy a Staticmaster brush.

- The transition from analog audio media to digital, and from phonograph players and tape recorders to digital media players and recorders too resulted in a decline in the demand of Staticmaster brushes, even if these could still provide some benefit when cleaning a Compact Disc or Digital Versatile Disc (DVD). But not too long after CD and DVD media came onto the market in 1982 and 1995, where is the need for a Staticmaster when streaming media and flash drives displaced disc storage?

- The transition from film to digital: from complicated and versatile film-based camera systems to simple and integrated pocket cameras and cell phones with cameras resulted in the elimination of darkrooms/film processing/film printing facilities. This virtually eliminated the demand of Staticmaster brushes, even though they still have some applications such as in cleaning CCD/CMOS sensors, in the other of its two formerly major markets.

|

|

Other reasons why Staticmaster may have been been going off the radar, so to speak, is likely related to:

- Many manufacturing companies have sought out distribution through larger volume resellers at the expense of smaller specialty stores. A homogenization of retailers has occurred, particularly over recent years, as consumers and manufacturers have allowed big-box and on-line resellers to displace local speciality stores. The NRD company sales policy changed too so that only those who could buy in larger volumes, could purchase directly from NRD, at the expense of smaller specialty stores.

If you look at what companies sell Staticmaster brushes today then there is little to differentiate one from another; they are all pretty much hosting the same photos and descriptions on-line as that provided by NRD in their literature.

- The short shelf life of the Staticmaster product complicates retailing efforts, moreso for lower volume resellers attempting to keep stock at hand for their customers. As a retailer may stock less and demand on-time inventory from NRD, this can complicate NRD’s factory stocking strategy too.

Consider our experience, Company Seven used to sell the Staticmaster. When Company Seven was founded NRD had been happy to fulfill orders for moderate quantities, accommodating the smaller volume retailer as well as the larger mail order oriented and chain store retailers. We continued to offer the product through about 2007 when our sales too declined in the face of lower floor traffic at our Laurel, MD showroom, and NRD insisted on larger volume of annual sales to retain retailer status. Of course the matter of our ordering larger volumes in an attempt to maintain stocks, more so to meet unpredictable demand, resulted in our ending up with greater numbers of outdated inventory. Regardless of that, Company Seven sensed the change of ordering policy was a mistake since NRD was essentially cutting off smaller but knowledgable retailers who might not sell as much product, but would still be promoting the line.

- Any manufacturer becoming so invested in so few resellers is more likely to become dependent on companies that often do not actively promote their product in the marketplace; that is putting the manufacturer’s own future at risk. But then there are fewer and fewer local retailers as consumers flock to on-line ordering. Staticmaster sales are now apparently so dependent on sales by the small number of larger companies, that if any of these decided to completely cut off sales simply in response to bad publicity or even if some unrelated story came out about Polonium for example, then that would make its future even more precarious.

- We have no way to judge industrial sales of these products though we do suspect here too, with increasing regulations and diligence - especially about safe disposal practices, that market too may have been impacted.

- Pricing: As volume of a product being manufactured decreases, then the costs per unit increase. As a manufacturer has fewer and fewer vendors too, then the manufacturer may be more and more at the mercy of the vendors to set pricing and other policies. As Polonium-210 was in the news (see above) other overhead costs such as insurance likely have increased. These factors may in some measure account for the dramatic increases in NRD retail pricing that we observed over the recent decade or so. Consider how in 2006 Company Seven sold the 1C200 Staticmaster® 1-inch brushes for $35.00, the 3C500 Staticmaster® 3-inch brushes sold for $45.00. By 2014 the 1-inch brush was selling from on-line resellers for $119.99, while the 3-inch brush was selling for $159.99. This becomes a harder sell in the tough economic times that the average consumer in the USA has experienced over the past decade, where sales even the top ‘1 percent’ cannot be enough to make up what the other ninety-nine percent cannot buy.

Such dramatic escalation of pricing and changes of availability, especially of a product that has an element with about a one year life-span, cannot bode well for the viability of any product line that is marketed in changing times and to the fickle unwashed masses.

|

Contents Copyright 1994-2025 Company Seven All Rights Reserved

|

![]() Distribution

Distribution ![]() News

News ![]() Notes & Interesting Articles

Notes & Interesting Articles ![]() Pricing

Pricing ![]() Products

Products

NRD LLC, currently owned by automotive systems and components manufacturer Mark IV Industries Inc., is the world’s largest and most experienced manufacturer of ionization sources for the home safety and industrial passive ionization and static control markets. NRD is an innovator in technology and products using Alpha and Beta emitters in encapsulated metallic foil. Their proprietary technology is used in a wide range of products and industries including industrial static eliminators, analytical equipment, gas chromatographs, smoke detectors, and explosives detectors. They remain a specialty source for Electron Capture Detector (ECD) and Ion Mobility Spectrometry (IMS) devices, and in addition they manufacture specialty ionizers for the auto body collision industry and the photographic market. The specially designed equipment and processes, along with a comprehensive quality assurance program (that must comply with Federal regulations), ensure these products meet the highest practical quality standards set by the US Nuclear Regulatory Commission.

NRD LLC, currently owned by automotive systems and components manufacturer Mark IV Industries Inc., is the world’s largest and most experienced manufacturer of ionization sources for the home safety and industrial passive ionization and static control markets. NRD is an innovator in technology and products using Alpha and Beta emitters in encapsulated metallic foil. Their proprietary technology is used in a wide range of products and industries including industrial static eliminators, analytical equipment, gas chromatographs, smoke detectors, and explosives detectors. They remain a specialty source for Electron Capture Detector (ECD) and Ion Mobility Spectrometry (IMS) devices, and in addition they manufacture specialty ionizers for the auto body collision industry and the photographic market. The specially designed equipment and processes, along with a comprehensive quality assurance program (that must comply with Federal regulations), ensure these products meet the highest practical quality standards set by the US Nuclear Regulatory Commission.

The “Staticmaster” static control product incorporates a Camel hair bristle brush mated to a thin film(s) of an encapsulated radioactive metal product that emits alpha particles. The alpha emitter is Polonium-210, a short-lived highly radioactive silvery metal product that occurs naturally in small amounts, but for industrial uses is manufactured in a nuclear reactor. Polonium-210 was discovered in July 1898 by Maria Salomea Skłodowska-Curie (Marie Curie) and husband Pierre Curie, and was named after her native Poland.

The “Staticmaster” static control product incorporates a Camel hair bristle brush mated to a thin film(s) of an encapsulated radioactive metal product that emits alpha particles. The alpha emitter is Polonium-210, a short-lived highly radioactive silvery metal product that occurs naturally in small amounts, but for industrial uses is manufactured in a nuclear reactor. Polonium-210 was discovered in July 1898 by Maria Salomea Skłodowska-Curie (Marie Curie) and husband Pierre Curie, and was named after her native Poland.

In the Spring of 1963 the design of the Staticmaster 1-inch brush body was again changed from the prior S style body to the C style, their being their third major 1-inch brush redesign. This newly styled brush was announced by June in trade magazine advertisements, and also in science and technology magazines. This new brush resembled the 1-inch brush design that remains in production through today with the tan plastic handle, but with a removable brown plastic panel and Polonium-210 cartridge, the brown being visible from the sides or from underneath. Removing the Phillips head screw that is accessed from above releases the Polonium-210 cartridge. This basic 1-inch model brush was designated the 1C 50 and sold for $4.95, with the replacement cartridge priced at $2.50. A higher output 1C 200 replacement cartridge could be ordered for $4.45. By about 1973 the brush moulded plastic handle and cartridge housing were both being made of matching tan plastic, and it is this arrangement that continues in production through today.

In the Spring of 1963 the design of the Staticmaster 1-inch brush body was again changed from the prior S style body to the C style, their being their third major 1-inch brush redesign. This newly styled brush was announced by June in trade magazine advertisements, and also in science and technology magazines. This new brush resembled the 1-inch brush design that remains in production through today with the tan plastic handle, but with a removable brown plastic panel and Polonium-210 cartridge, the brown being visible from the sides or from underneath. Removing the Phillips head screw that is accessed from above releases the Polonium-210 cartridge. This basic 1-inch model brush was designated the 1C 50 and sold for $4.95, with the replacement cartridge priced at $2.50. A higher output 1C 200 replacement cartridge could be ordered for $4.45. By about 1973 the brush moulded plastic handle and cartridge housing were both being made of matching tan plastic, and it is this arrangement that continues in production through today.