U.S. Navy Mark XLIV Mod. 0 Binocular, SARD 7x 50 Of World War II

A historic product exhibited among others in the permanent collection at Company Seven

On 6 February 2016 Company Seven acquired a World War II era U.S. Navy issued 7x 50 Porro Prism binocular set, specifically a SARD Mark XLIV Mod. 0. This is now on permanent exhibit at our showroom museum collection of interesting or significant optics.

On 6 February 2016 Company Seven acquired a World War II era U.S. Navy issued 7x 50 Porro Prism binocular set, specifically a SARD Mark XLIV Mod. 0. This is now on permanent exhibit at our showroom museum collection of interesting or significant optics.

Right: as new U.S. Navy SARD 7x50 Mark XLIV Mod. 0. Image courtesy collection of Company Seven (73,613 bytes).

Click on image to see enlarged view (245,393 bytes).

This is not the first or the sole U.S. Navy issue item on exhibit here, but this binocular certainly sparked a good deal of excitement here because this is:

- among the pinnacle of general purpose 7x 50 binoculars employed by the greatest naval force ever engaged in war: the United States Navy*,

- the SARD brand retains respect and admiration bordering on a mystique, most of it appropriate, by some who rave about WW II binoculars.

- These were manufactured en masse by The Greatest Generation: men and women who developed a qualitative edge in technology, superior manufacturing capacity, and who made up the forces that with adaptable leadership and some guts too defeated Hitler, Hirohito, and their minions.

- The condition of this binocular is in our experience unprecedented: literally old new stock in it’s original packing carton as completed 72 years ago.

*at it’s peak in August 1945 the U.S. Navy was operating some 6,768 ships (vessels 100 feet or longer) including: 23 battleships, 28 aircraft carriers, 71 escort carriers, 72 cruisers, more than 288 submarines, 377 destroyers, and thousands of patrol, amphibious, supply, and auxiliary ships. Consider there were many other classes too including 544 PT Boats, and some 82,266 landing craft built during the war! Every vessel required binoculars.

The excitement needed to be shared with those who have helped to keep Company Seven around for well more than three decades, and so we elected to write about this binocular in the context of it’s place among the other 7x 50mm models that were made for the U.S. Navy Bureau of Ships during World War II. In time as we acquire or restore presentable examples of other U.S. military binocular models we will write about them too.

If you wish to learn more about how the U.S. Navy developed their own optics shop, and about how during World War II some 7x 50mm models were converted by the Naval Gun Factory Optics Shop to 9x 63, then you should read our article U.S. Naval Gun Factory Mark 37 - 9x 63 Binocular Of World War II. We will avoid duplicating information there in this article unless it helps this stand on it’s own.

Organization While Approaching War:

Going into World War II the United States Navy Department was an independent branch of the military. In time of war the U.S. Coast Guard, formerly operating as a separate service, becomes administered under the Navy Department. The U.S. Maritime Commission was transferred to the U.S. Coast Guard. The Marine Corps too were an independent branch but that cooperated with the Navy, while the Marine command reported to the Secretary of the Navy. The United States Department of War administered both the U.S. Army ground and U.S. Army air forces, though even then the Army Air Corps was a distinct branch of the Army that by June 1941 would become even more autonomous as the United States Army Air Forces (USAAF). In times of war or other national emergency the resources of the National Guard were administered by the Army. Support organizations that in time of war might work under or coordinate with the military included coast watching, civil defense, and intelligence services (including the FBI) for example.

Each military branch of service was supported by their own administrative and logistical operations. As each had different missions, the requirements for their hardware was often specified by each branch of the military service. Furthermore, since each branch of the military operated a variety of missions then hardware for the specific missions too was specified or adapted to suit.

U.S. Navy organizations that were largely responsible for procurement in 1940 were designated Bureaus, each commanded by a Rear Admiral. These Bureaus included: Aeronautics, Engineering, Navigation, Ordnance, and Ships. So the fleet of surface combat and support ships, of submarines, of Coast Guard and of Maritime Service vessels, along with most of their instruments and consumables too, were largely specified by and contracted for by the Bureau of Ships (BUSHIPS, or sometimes designated BU.SHIPS). Navy personnel, charts and weather monitoring were managed by Navigation (NAV). Optics required for the aviation mission were administered by the Bureau of Aeronautics (AERO), while optics for gunnery support for everything from antiaircraft to the big guns of the battleships would be acquired through the Bureau of Ordnance (ORD). This fiscal year also saw a major reorganization of the Navy Department, putting all material under management of the Bureau of Ships.

The Navy directly controlled some production capacity including shipbuilding and repair at Navy Yard facilities, some repairs could be made at overseas bases too. The historic Washington Navy Yard occupies some 125 acres along the Anacostia River in Southeast Washington, D.C., here were design and manufacturing facilities including the massive Naval Gun Factory for the production the immense gun barrels and liners for the battleships. Here too was the optical shop whose craftsmen produced lenses and prisms, telescopes and stadimeters (optical rangefinder). They also provided repair and maintenance services for a large number of telescopes, range finders, binoculars, and spotting glasses. The optics shop predated World War I, but in 1917 a private factory in Rochester, New York was taken over and designated the U.S Naval Gun Factory Optical Shop Annex at Rochester, N.Y. In 1919 the factory equipment and most personnel too were relocated from Rochester to the Washington Navy Yard, here the optics shop had their own new 63,500 square foot Building 157, this also hosted the U.S. Navy optical repair trade school. An optical repair shop was also established at Mare Island Navy Yard, with facilities for repairing optical instruments of the Pacific Fleet. However, the military alone lacked the in-house manufacturing capacity necessary to meet the demands of a World War so ships, aircraft, armor, guns, and anything else needed for war including binoculars too were manufactured under contract.

Organizing For War Production:

Late in the 1930’s the prospect of war became more obvious to the American Congress; planning had commenced and manufacturing had been contracted to modernize the military. In the United States a strong Executive and cooperative Congress passed legislation that enabled and even streamlined procurement for the U.S. and for allied nations. In 1940 the U.S. government designated a number of manufacturing entities as being among defense industries: aircraft, shipbuilding, automotive, etc. The Lend-Lease programs to aid allied nations caused the building of the Arsenal of Democracy to become intensified. Some of the more important changes in methods of procurement resulted from the act of 28 June 1940, “To Expedite Naval Shipbuilding, and for Other Purposes”, which contained legislation to streamline contracting for national-defense program. In the annual report by the Secretary of the Navy, Frank Knox reported that the fiscal year ending in June 1941 had seen an 800 percent increase in contracts executed in the Bureau of Supplies and Accounts over the previous year.

Even before the war, in light of the increasing demands for defense production, many plant managers established apprenticeship programs to teach graduates of technical high schools how to read blueprints and operate manufacturing equipment. These “learnership” employees were paid to learn and gain experience in programs that were planned to span about two and one-half years. The demand for skilled labor increased so much that by 1940 defense contractors were competing for talent and advertising for skilled and learnership employees, even scouting for future hires at area high schools and focusing on those with schools technical (vocational) education programs. As early as February 1940 some manufacturers were already in touch with some students who were nearing graduation months later.

After Japan attacked Pearl Harbor and Germany declared war on the United States, America dramatically increased the rate and scale of mobilization. The United States adapted for wartime production rapidly and with total commitment; the population had become galvanized by Pearl Harbor, and it too mobilized to conserve vital materials (rubber, nylon, gasoline, etc.) and contribute metals and other materials for recycling into weapons.

The ramping up of manufacturing to operate at up to 24 hours per day, and 7 days per week happened very quickly. In addition to seeking new hires, companies established accelerated upgrading courses to speed learning and training of current employees so they could promote to the more demanding and better paying job, their prior position would be filled by others being promoted or by new hires.

Adapting And Standardization During War:

The Emergency Training for National Defense organization trained potential hires to read blueprints, use drafting equipment and measuring micrometers, and to operate basic manufacturing equipment so these students too could be readied to be hired by manufacturing companies. By January 1942 it was also apparent to organizations, including the Board of Education in many states, that most manufacturing and other jobs too would be opened to women. So the education programs and facilities too were modified to accommodate that reality. They opened supplementary and pre-employment courses to anyone male or female aged 17-½ or older for positions in the defense industries. In New York City however, they initially resisted placing women into these jobs as they had some 300,000 men listed on unemployment rolls; the U.S. was still coming out of the Great Depression after all but this was rescinded early in 1942 and women were placed onto a more equal footing for training and employment. As women joined the work force this freed manpower from manufacturing to join the armed services and civil defense organizations.

The Emergency Training for National Defense organization trained potential hires to read blueprints, use drafting equipment and measuring micrometers, and to operate basic manufacturing equipment so these students too could be readied to be hired by manufacturing companies. By January 1942 it was also apparent to organizations, including the Board of Education in many states, that most manufacturing and other jobs too would be opened to women. So the education programs and facilities too were modified to accommodate that reality. They opened supplementary and pre-employment courses to anyone male or female aged 17-½ or older for positions in the defense industries. In New York City however, they initially resisted placing women into these jobs as they had some 300,000 men listed on unemployment rolls; the U.S. was still coming out of the Great Depression after all but this was rescinded early in 1942 and women were placed onto a more equal footing for training and employment. As women joined the work force this freed manpower from manufacturing to join the armed services and civil defense organizations.

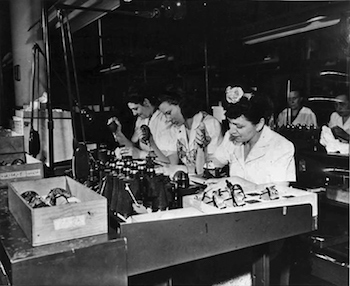

Right: Square D Corporation SARD binoculars undergoing assembly, note the ladies contributions to the war effort (58,686 bytes).

Participants already employed could be referred to defense industry training courses by either an Advisory Board on Vocational Education, or by a current employer, or by a Trade Union. For for the unemployed there were other avenues including a Trade Union (through the Advisory Board), the WPA, or by a U.S. Employment Service office. Commencing 2 February 1942, New York put into effect defense training courses specifically for High School students, these counted as one credit towards graduation and were offered in addition to normal schoolwork.

Many companies formerly making products for the consumer were geared up to manufacture wartime commodities. At first glance it often seemed that many companies were manufacturing items for war that had little to do with what the company had manufactured in peacetime, but manufacturing expertise is manufacturing expertise. Automobile companies built armored vehicles and tanks, aircraft, and small arms. Franklin Instruments of Pennsylvania, who manufactured clocks before the war, continued to make such instruments but also adapted to manufacture pedestal-mounted “Big Eye” 120mm binoculars along with Kollmorgen Optical Co. in Massachusetts. Many new companies too sprouted up to compete for their share of lucrative defense contracts.

In the field of optics two of the more notable established manufacturers of binoculars in the United States were Bausch & Lomb Opt. Co. of Rochester, New York, and Spencer Lens Company (American Optical), of Buffalo, New York. There was much cooperation between the manufacturing companies, so Bausch & Lomb could provide prisms and lenses or complete instruments to other companies for integration into their larger systems. Wartime production designs were standardized as much as practical so that parts made by one company could be interchanged with parts made by another during final assembly, this was helpful in streamlining repairs at facilities closer to the combat areas. To that end Bausch & Lomb licensed it’s designs and assisted six other companies including Kollsman Instrument Co., Universal Camera Corp., and Anchor Optical Corp. to gear up for mass production while also standardizing the binoculars.

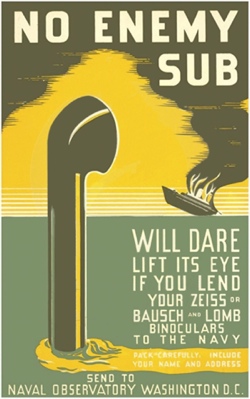

Accommodation For War: As had been the case when the United States entered World War I, in 1942 the military did not possess enough binoculars to meet the impending needs of their rapidly growing forces. The manufacturer’s that would in time meet that demand were just starting to gear up for war, their escalating production would not meet the demand for a year or more. So in the interim the government issued appeals for consumers to loan their better binoculars for the war effort. In a replay of the Eyes for the Navy program of 1918, in the U.S. Navy asked civilians to send in their binoculars for evaluation of suitability for service, these were sent to The U.S. Naval Observatory, in Washington, D.C. It is an interesting commentary about how well regarded Carl Zeiss Jena optics were in the years leading up to World War II when the U.S. government published advertisements asking the public to loan their personal binoculars for the war effort the ads specifically mention Zeiss and Bausch & Lomb. It is somewhat ironic that Zeiss optics were pressed into service against the very U-Boats that Zeiss supplied with binoculars and periscopes.

Accommodation For War: As had been the case when the United States entered World War I, in 1942 the military did not possess enough binoculars to meet the impending needs of their rapidly growing forces. The manufacturer’s that would in time meet that demand were just starting to gear up for war, their escalating production would not meet the demand for a year or more. So in the interim the government issued appeals for consumers to loan their better binoculars for the war effort. In a replay of the Eyes for the Navy program of 1918, in the U.S. Navy asked civilians to send in their binoculars for evaluation of suitability for service, these were sent to The U.S. Naval Observatory, in Washington, D.C. It is an interesting commentary about how well regarded Carl Zeiss Jena optics were in the years leading up to World War II when the U.S. government published advertisements asking the public to loan their personal binoculars for the war effort the ads specifically mention Zeiss and Bausch & Lomb. It is somewhat ironic that Zeiss optics were pressed into service against the very U-Boats that Zeiss supplied with binoculars and periscopes.

Right: one of the U.S. Navy advertisements soliciting civilian binoculars, this was printed in 1942. The text of that ad is below (44,401 bytes).

Click on image to see enlarged view.

No Enemy Sub Will Dare Lift Its Eye If You Lend Your Zeiss

Or Bausch and Lomb Binoculars To The Navy

Pack Carefully, Include Your Name And Address

Send To Naval Observatory Washington D.C.

The newly arrived civilian binocular would be inspected and if found suitable for naval use it would have a Serial No. and owners name too engraved for identification purposes. The number would be a four or five digit number followed by a dash and the year. So it is possible to find binoculars that were originally made and trademarked for the consumer market bearing military identification markings.

Since regulations of the day prohibited Federal agencies, including the military, from the accepting of gifts or free loans the owner of the loaned binocular had to be compensated. So the owner received a letter from the Navy Bureau of Ships confirming the loan and providing them with the assigned serial number, the letter also enclosed a Public Voucher form to be completed and signed by the citizen. Upon return of that voucher the Navy would issue a check in the amount of one dollar, the same amount they paid in 1918, that “releases the Navy from any obligation should the binoculars be lost. All possible care will be taken, however, to insure their return at the end of the war.” After the war the owners whose binoculars could not be returned were contacted again by the Navy and offered compensation.

- Anchor Optical Corporation, New York, New York

- Bausch & Lomb Optical Company, Rochester, New York

- Hayward Lumber & Investment Co., Chemical & Manufacturing Division, Los Angeles, California

- National Instrument Corporation, Houston, Texas

- Optical Film & Supply Co., New York

- SARD Square D Company (Kollsman Instrument Company, Inc.), Elmhurst and Flushing, New York

- Spencer Lens Company (division of American Optical Company), Buffalo, New York

- Universal Camera Corp, New York, New York

- Shock: the Navy technical manual refers to a post-servicing shock test specifying “it will be dropped from a height of six feet into a sand box filled six inches deep. Then the optical alignment will be rechecked on a collimator”. In terms of usability and optical performance including light transmission, these U.S. Navy binoculars are not bested by any other 7x 50 then in production.

- Optical Resolution: “objects in the center of the field of view that subtend an angle of 4 seconds of arc shall be clearly resolved. In terms of the test to be made, equal width lines equally spaced 0.018 inches on centers shall be clearly visible as separate and distinct when viewed at 77 feet.”

- Image Fidelity: performed on special apparatus to evaluate astigmatism and central resolution that might point to optical problems

(objective lenses, shifted prism or prism cluster, etc.). - Waterproof: an underwater pressure test to insure the seals must withstand a pressure of 3 pounds per square inch.

- Light Transmission: “the binocular shall transmit at least 75 percent of the white light being viewed and that the transmission of the two telescopes shall not differ by more than 3 percent..”.

Those models that were mass produced during the war for hand held uses included 6x 30mm, 7x 35, 7x 50, 8x 56, 10x 50, and 10x 70. There were comparatively fewer numbers of some specialty or experimental models made including the 6x 42, and the U.S. Naval Gun Factory Mark 37 - 9x 63 binocular. For use in low light conditions of dawn, dusk, night or during inclement weather the 7x 50 was a most popular choice. For shipboard use or reconnaissance on land the 7x 50 tended to be preferred as it provides excellent balance for hand holding, reasonably wide (Approx. 7.2 Degree) field of view, and large exit pupil that made them well suited for low light work and comfortable to line up and look through. Where light gathering power was less a concern or where being able to carry was as important, smaller binoculars including the 6x 30 were issued.

While several companies manufactured binoculars during World War II for other services and for branches of military service, and even for the various Bureaus of the Navy, those manufacturers contracted to fabricate 7x 50 Porro binoculars specifically for the BUSHIPS include:

C.F. or I.F.? For reasons of practicality military binoculars tend to be built with the Individual Focus (I.F.) mechanical arrangement. This is where the user rotates the upper barrel of the left and right eyepiece independently to focus the binocular to infinity. Once the focus has been set it need not be changed and is not likely to shift on its own; every time you pick up the binocular the view will be sharp and with no time wasted adjusting the single focus dial as on a Central Focus (C.F.) binocular that do tend to shift focus at times almost just sitting still. I.F. is especially desirable at sea in foul weather since precious seconds might be wasted trying to determine what is the best focus point while looking out for another ship coming at you in a fog for example. Since each I.F. binocular eyepiece bears a calibrated diopter scale (indicating + and - diopter symbols) it is a simple matter to share a binocular with someone even if they need to change the setting, since upon return of the binocular the primary user can reset the focus without even having to look through the glass. The I.F. arrangement makes perfect sense since in most naval or airborne uses the binocular would be adjusted to the infinity focus for observing objects hundreds of feet away if not miles distant. Furthermore, this arrangement is much easier to produce in a waterproof configuration, and will be far more resistant to the elements or to impact than binoculars made with a C.F. arrangement. A birder or nature watcher who constantly change focus for optimum observing of objects that may be very close then out to infinity would find the C.F. arrangement to be more convenient.

The Issue Binocular Mark and Mod Designations: a binocular that is well suited for one type of use within any one or multiple branches of service might not have been as well suited for use in another application. The particulars could have to do with matters of magnification and field of view, aperture and low light capabilities, or durability at sea or in an aircraft environment, even special lubrication and seals for extremely cold climates. Subtle differences could include design of the provided eyecups, or rubber face guards (for better comfort over extended observing sessions). For some missions it could be important to make provisions for the binocular to accept or be provided with filters; such a facility could be cause to designate the new or modified binocular as a separate model or variant of a model. To abbreviate missions for which a product was designed the armed forces employ acronyms, line or mark item numbers, or other devices. In the case of military binoculars the Navy relied on a term “Mark x”, and this may bear some additional suffix “Mod x” designation.

Company Seven is aware of some thirty-seven (37) models of BUSHIPS contracted 7x 50 binoculars whose variants entered production at one time or another over the period from 1940 to 1945. Most were largely based on the highly successful B&L design that fundamentally originated with the B&L binocular Patent (no. USD83934) of January 1931, and changed with only some technology improvements over the decade leading into World War II. The B&L Mark 28 Mod 0 was the most mass produced version 7x 50 binocular, the records at Company Seven account for at least 340,000 being made and our records are not complete. Most of the binoculars made for the U.S. military being so well constructed that many remain in routine civilian use while there is not a day in our era when several are not being marketed for sale used in auction sites, classified advertising, and pawn shops.

There were several binocular models produced that were tailored to serve more than one branch of service, or for multiple Bureaus of the Navy. For example, Bausch & Lomb produced binoculars contracted in 1941 bearing the Mark I Mod. I designation. While most were produced for the U.S. Navy, some were issued to the U.S. Coast Guard (procured in peacetime through the U.S. Department of the Treasury), and with a serial number such as “CG No.xxxx” corresponding in sequence to those Mark I Mod. 1 binoculars produced for the U.S. Navy. Company Seven's records indicate the U.S. Coast Guard was among the first to receive Mark I Mod. I binoculars.

Examples of a model being adapted for multiple roles include the Mark 21, a 7x 50 binocular contracted to be produced by both B&L and also by SARD. The Mark 21 closely resembled the other B&L 7x50 binoculars, sharing similar optical components and even appearing similar with their vinylite exterior handgrip finish that were expedient at the time. The Mark 21 specification 29329-C calls for a binocular with winged eye guards, and with hinged rotatable (horizontal through to vertical) polarizing filters fitted over their eyepiece that could be dialed in or off the line of sight or that can swing out for cleaning. Because the Mark 21 were contracted early in the war and produced for more years, there are many times more Mark 21 binoculars produced and surviving today than the SARD Mark XLIV binocular contracted in 1944.

Bausch & Lomb Mark 28 Mod 0 can be found labeled BU.ORD with standard eyecups for example, or labeled BU.AERO with either standard or winged eyecups (to block light from the sides), or a version of that was labeled “BINOCULAR M7” when made for the Army.

When the mission was to observe movement across a wide expanse of sky or water, a binocular with a much wider field of view was justified. Several wide angle binocular models were commissioned specifically for the Bureau of Aeronautics whose vital work included reconnaissance (searching for U-Boats and other enemy ships), as well as search and rescue; these bear the designation “BU. AERO”. A noteworthy model developed for AERO is the SARD Mark 43 6x 42 WIDE ANGLE that was designed and manufactured by Kollsman Instrument in Flushing, New York. The Mark 43 binocular is among those extraordinary accomplishments that put the SARD name into prominence. The Mark 43 provides an actual field of view some 11 degrees 50 minutes (or 11.8 Deg.) wide! To comprehend what an accomplishment this was, consider the Mark 43 allows the user to view an area about 2.7 times larger than that which can be observed through a typical 7x 50mm binocular that was made then or today. With 42mm objectives and a generous 7mm diameter exit pupil the Mark 43 provides good light gathering power, the optical aspects combined with the provided custom rubber face guard to insure a more comfortable long term observing experience for the user. On the other hand, for routine handheld use there would be no justification for providing the 1.3x heavier and more costly Mark 43 binocular when a general purpose 7x 50 with a field of view of about 7.2 degrees would be sufficient. Furthermore, a good 7x 50 binocular with similarly MgFl antireflection coated optics would provide about 1.4 times better low light performance (18% better twilight performance) than the the Mark 43

When the mission was to observe movement across a wide expanse of sky or water, a binocular with a much wider field of view was justified. Several wide angle binocular models were commissioned specifically for the Bureau of Aeronautics whose vital work included reconnaissance (searching for U-Boats and other enemy ships), as well as search and rescue; these bear the designation “BU. AERO”. A noteworthy model developed for AERO is the SARD Mark 43 6x 42 WIDE ANGLE that was designed and manufactured by Kollsman Instrument in Flushing, New York. The Mark 43 binocular is among those extraordinary accomplishments that put the SARD name into prominence. The Mark 43 provides an actual field of view some 11 degrees 50 minutes (or 11.8 Deg.) wide! To comprehend what an accomplishment this was, consider the Mark 43 allows the user to view an area about 2.7 times larger than that which can be observed through a typical 7x 50mm binocular that was made then or today. With 42mm objectives and a generous 7mm diameter exit pupil the Mark 43 provides good light gathering power, the optical aspects combined with the provided custom rubber face guard to insure a more comfortable long term observing experience for the user. On the other hand, for routine handheld use there would be no justification for providing the 1.3x heavier and more costly Mark 43 binocular when a general purpose 7x 50 with a field of view of about 7.2 degrees would be sufficient. Furthermore, a good 7x 50 binocular with similarly MgFl antireflection coated optics would provide about 1.4 times better low light performance (18% better twilight performance) than the the Mark 43

Above: comparing a U.S. Navy standard 7x 50 binocular (Bausch & Lomb Mark I Mod 2) alongside a SARD Mark 43 Wide Angle binocular.

The Mark 43 prism housings and eyepieces are much larger, and with a weight of 1718 grams their nickname 'Fat Boy' seems appropriate.

Both in Company Sevens collection (99,433 bytes).

The Navy procurement people were keenly aware that a more complicated product would also require more time and materials resources to produce and to maintain, so not every soldier or sailor had to the have a Mark 43 when a less costly 7x 50 alternative such as the Bausch & Lomb Mark 28 Mod 0 would suffice or could even be superior in some aspects.

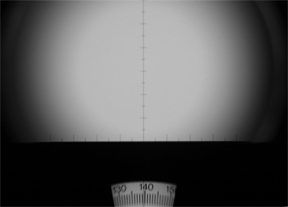

Many military issue handheld binoculars were built incorporating a reticle, this is a pattern of lines built into an eyepiece and overlying the field of view. The reticle aids the observer in determining distances, spotting the fall of artillery (aerial, mortar, or naval guns) and more. However, the reticle could be a distraction to someone who is engaged in sweeping the skies for aircraft or panning the horizon looking out for an approaching vessel. The Bureau of Aeronautics (AERO) and Bureau of Ships (BUSHIPS) ordered versions of the Mark 28 handheld 7x 50 binocular, these were improved general purpose models assembled since 1943 and with eyepieces that do not incorporate a reticle. The same basic Mark 28 binocular manufactured for BUSHIPS were also contracted by BU.ORD and these were assembled as a variant that incorporates a reticle, this configuration was designated the Mark 39 Mod 1. Some modifications could have been made during the course of servicing, that could confuse someone searching out an old binocular. So for example it was possible for an optics technician to install a new reticle from stock or to remove it, so one might encounter a Mark 39 Mod 1 binocular without it’s reticle, or a Mark 28 with reticle.

Many military issue handheld binoculars were built incorporating a reticle, this is a pattern of lines built into an eyepiece and overlying the field of view. The reticle aids the observer in determining distances, spotting the fall of artillery (aerial, mortar, or naval guns) and more. However, the reticle could be a distraction to someone who is engaged in sweeping the skies for aircraft or panning the horizon looking out for an approaching vessel. The Bureau of Aeronautics (AERO) and Bureau of Ships (BUSHIPS) ordered versions of the Mark 28 handheld 7x 50 binocular, these were improved general purpose models assembled since 1943 and with eyepieces that do not incorporate a reticle. The same basic Mark 28 binocular manufactured for BUSHIPS were also contracted by BU.ORD and these were assembled as a variant that incorporates a reticle, this configuration was designated the Mark 39 Mod 1. Some modifications could have been made during the course of servicing, that could confuse someone searching out an old binocular. So for example it was possible for an optics technician to install a new reticle from stock or to remove it, so one might encounter a Mark 39 Mod 1 binocular without it’s reticle, or a Mark 28 with reticle.

Left: image of a binocular that incorporates a Compass Bearing with Ranging Reticle (117,110 bytes). Courtesy Company Seven.

In another example, missions involving the United States Marine Corps were aided by binoculars fitted with a reticle to help the observer judge distance. So a Bausch & Lomb Mark 28 Mod 0 binocular fitted new (or later retrofitted) with the reticle would bear the Mark 46 labeling, and this is would also be engraved “U.S. MARINE CORPS”. Similarly the Anchor Optical produced Mark 32 variant with reticle made for the U.S. Marine Corps is labeled Mark 40 binocular. Several binocular models originally developed for the U.S. Navy were contracted for production in the United States or licensed for production in Canada for delivery to allied military forces including those of England.

A targeting binocular with reticle designed to be left attached to the conning tower of a submarine or it’s deck gun would have to be made to endure shock and pressures of water and waves, so BU.ORD set forth the specifications for what became the Mark 38, or later the Mark 91. BU.ORD administered the contracting to have these manufactured by Bausch & Lomb.

By assigning an easy to reference Mark designator to a production series this also expedited communicating about them between the Navy organizations. As newer improved production came available it was easier to identify and replace older models. For example, in September 1943 the Bureau of Ordnance communicated to all Navy Yard optical officers an order to obsolete all Binocular Marks from 1 to 12, among other optical components (periscopes, telescopes, rangefinders) being phased out; this basically commanded those older binoculars no longer be repaired but replaced when possible.

The type and quantity of each binocular, as was the case with virtually every piece of equipment, were allocated by the Navy Ship Allowance List. Every U.S. Navy, Coast Guard, and Maritime Service vessel, from the battleships down to a PT boat, and cargo vessels too would have so many 7x 50 binoculars of a particular Mark designation allocated to it: no more and (hopefully) no less. In keeping with military necessity there were specialists trained and certified to perform maintenance and repairs, these could be civilian employees working at a Navy base or sailors assigned to warships and auxiliary vessels including ships that specialized in providing repairs. In the case of most BUSHIPS 7x 50 binoculars they referred for guidance to the “Manual for Overhaul, Repair and Handling of 7x50 Binoculars with Parts Catalog” we refer to a later copy of that NAVSHIPS publication No. 250-624-2 from 1951.

The year stamped on a binocular prism cover will represent when that specification was first contracted, that does not necessarily indicate when a particular binocular was manufactured. So for example, a Mark 28 binocular bearing the 1943 imprint on the prism cover might have been manufactured in 1945. Some production lots will bear a serial number or a production date code, this may be the letters code and numbers stamped on the hinge front cover of many B&L binoculars for example. Unfortunately many binoculars ordered for BU.AERO and by others too may bear no serial number or date code. It is only by understanding these markings, then comparing them to factory production records, then one might be able to date a binocular. But consider too how so many years after production it is also possible that components may have been interchanged between similar binoculars; a binocular that shows signs of tampering or repair is less likely be one hundred percent original.

The Path To Production: once a new requirement was identified the government would solicit proposals, at times even paying for some of the up front costs of design. After the designs were approved then the detailed production drawings (blueprints) would be prepared that included: Outline View (exterior), General Arrangement, and Optical Arrangement. A “General Arrangement Mark xx” number was assigned to the manufacturing drawings and to the contract paperwork. The suffix of each number indicated the originator, with O indicating BU.ORD, S indicating BUSHIPS, C indicating a customer’s drawing. A General Arrangement letter suffix might indicate it originated in the Navy even if it was made for the another branch of service, the U.S. Army or the U.S. Coast Guard by BU.ORD for example. This process facilitated distributing the necessary design information that would insure consistency among the various assigned manufacturers. In time the contracting process changed from referring to these items by General Arrangement number and instead assigned a Federal Stock Number (FSSN) to each product.

The Path To Production: once a new requirement was identified the government would solicit proposals, at times even paying for some of the up front costs of design. After the designs were approved then the detailed production drawings (blueprints) would be prepared that included: Outline View (exterior), General Arrangement, and Optical Arrangement. A “General Arrangement Mark xx” number was assigned to the manufacturing drawings and to the contract paperwork. The suffix of each number indicated the originator, with O indicating BU.ORD, S indicating BUSHIPS, C indicating a customer’s drawing. A General Arrangement letter suffix might indicate it originated in the Navy even if it was made for the another branch of service, the U.S. Army or the U.S. Coast Guard by BU.ORD for example. This process facilitated distributing the necessary design information that would insure consistency among the various assigned manufacturers. In time the contracting process changed from referring to these items by General Arrangement number and instead assigned a Federal Stock Number (FSSN) to each product.

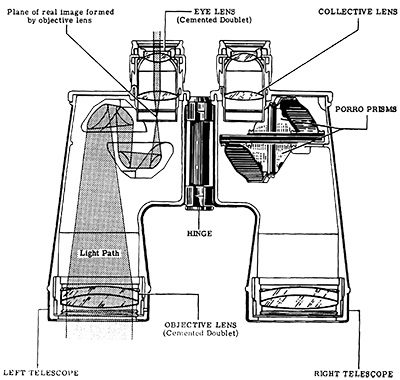

Right: typical optical arrangement of the wartime U.S. Navy 7x50 handheld binocular (117,444 bytes).

Click on image to see enlarged view (132,514 bytes).

A particular binocular design might have been needed in such large quantities that multiple companies would be contracted to meet the demand. Consider for example the Mark 32, a 7x 50 binocular whose production was assigned to: Anchor, National, Universal, and some were even contracted to Perfex although that contract was cancelled in 1945. Each contracted Mark 32 production lot bore a ’Mod x’ designation to reflect the assigned manufacturer. So the Mod 0 suffix indicated that Mark 32 was made by Anchor, the Mark 32 Mod 1 was the designation assigned to National, and so on.

A binocular trade name might not exactly correspond to the company name that was assigned the contract. For example we have read of some contracts awarded to Square D Company’s Kollsman Instrument Division however, their binoculars bear the SARD trade name. Kollman had been contracted to produce other optical instruments too, including spyglass telescopes, when they were contracted to manufacture binoculars. The first binocular to bear the SARD name were their Mark 21, first contracted by the U.S. Navy for BU. AERO (F.S.S.C. 88-B-320) with $369,000.00 allocated on June 1942, and with completion expected by February 1943.

As the end of the war was in sight some BUSHIPS contracted binocular models never were produced, these included: the Mark 32 Mod 3 assigned to Perfex, the Mark 34 and Mark 35 Mod 0 contracted to Ajax. There was only one version of the Mark XLIV binocular assigned, this was the Mod. 0 contracted to SARD that entered production late in 1944.

U.S. Navy binocular Mark designations of this era could be Arabic or Roman numerals. The binocular itself may bear either, and technical documents might refer to the same instrument by either nomenclature. All SARD Mark 44 binoculars for example bear “Mark XLIV”. SARD made other models of binocular for the war, these other models including the Mark 21 made for the Aeronautical Bureau of the U.S. Navy for example bear the designation in Arabic numerals. In order to simplify reading of the designations, on 17 April 1944 BuShips ordered the designation labeling be standardized, moving away from use of Roman numerals and to Arabic numbers for products contracted from then on. We at Company Seven do not know why the Mark designations assigned before this were a mix of Arabic and Roman numerals, but we remain open to information that would explain why.

The Mark XLIV was preceded by many other versions of similar 7x 50 that were in production since 1943 including the Mark 28, the Mark XXXII made by Anchor Optical, and the Mark XXXIII manufactured by Universal Camera Corp. There were other 7x 50 binoculars made for BUSHIPS that that bore the designations Mark 32 or Mark 33 in Arabic numerals, these were made by companies including Anchor Optical Co.

The uniformity and standardization of designs facilitated not only manufacture, but also facilitated maintenance and repair or even the upgrading or modifying of some equipment during the course of the war. For use in some theaters a particular Mark and Mod binocular may have had two desiccator modules installed, one in each prism housing, while doing this for some other models (the Mark 39 Mod 1 for example) was explicitly prohibited by BUSHIPS. The media holding some cemented objective lenses together might fail in a particularly harsh climate so an alternative, even if more costly to make, might be authorized just for fitting to binoculars destined for use in that region. Many wartime 7x 50 binocular models incorporated 52mm diameter objective lenses with a 190mm focal length, this explains why so many 27mm focal length eyepieces and 50mm finder telescopes were still being furnished with amateur telescopes being sold new well into the 1980’s: their sellers were simply modifying surplus new old stock lenses and eyepieces to fit.

New technologies were coming out almost daily and for optics this included antireflection coatings developed in 1935 by the Carl Zeiss Jena company. Dr. A. F. Turner of the Scientific Bureau of the Bausch & Lomb Co. developed a more durable Magnesium-Fluoride treatment that are optimized for the yellow-green, this region of the visual spectrum is the peak of sensitivity for the human eye. These coatings are only four-millionths of an inch thick but when applied on all air to glass surfaces, increased light transmission through a binocular and in the case of a 7x 50 this might mean an increase of from 57.8% to 75% overall and with a reduction of ghosting and flare. First applied for commercial optics by B&L in 1939, by 1941 they were approved for service use and were finding their way into military optics. By 1943 the lenses and prisms of most U.S. military binoculars were being made with these AR coatings*. After the war these coatings were marketed by B&L under the trade name “BALCOTE®”.

As binoculars were returned to U.S. military service centers, those Mod version binoculars approved for the change would have their original uncoated lenses and prisms replaced with optics incorporating the recently developed antireflection coatings. There may be some marking or labeling to indicate the optics had been upgraded; for example the right prism cover could stamped near the binocular model designation with an additional “TREATED M.I.N.Y.” indicating the service was performed at the U.S. Navy's Mare Island Navy Yard. A stick-on label could have been applied, this would resemble that on the SARD Mark XLIV featured in this article.

-

* The lenses of World War II era binoculars provided with the AR coatings exhibit a distinct purplish tint. Those accustomed to older uncoated optics and not acquainted with the new coatings might after noting the tint become concerned that something had contaminated the binocular, this resulted in many early binocular coatings being damaged by people trying to clean off the AR coating. Coatings could be damaged by improper cleaning techniques too. As a result manufacturers applied labels warning users about the coatings. For those who seek more information about proper cleaning techniques, Company Seven hosts an article Cleaning Telescopes And Most Consumer Optics.

Right: Company Seven’s SARD Mark XLIV showing the prominent coated optics warning label, typical of those applied to the wartime U.S. Navy binoculars (57,165 bytes).

Click on image to see enlarged view (109,529 bytes).

The U.S. Army and U.S. Navy technical manuals specified other improvements that were to be made when an optical item came in for service or repair. Servicing might involve improved sealing against water with later production components replacing an original obsolete part. So for example, the U.S. Navy Mark 32 binocular was made in seven different Mods (0, 1, 2, 4, 5, 6, 7) but whenever earlier Mods of the Mark 32 binocular arrived for service they would be upgraded to the Mark 32 Mod 7 configuration that improved waterproofing of the eyepiece. The technical manuals even specified what special tools and skill level was required to service each binocular; in the U.S. Navy an Optical Instrument Assembler, Junior Grade being sufficiently skilled to perform disassembly and routine maintenance of most handheld 7x 50 binoculars while repairs and reassembly would be assigned to an Optical Instrument Assembler, Senior Grade.

A Brief Diversion - The Mark 45: the Mark XLIV Mod. 0 by SARD, and the

The Mark 45 entered production in mid 1944, it is similar to the general purpose U.S. military service 7x 50 binoculars, even sharing some components. So the quality of view, and the fifty-one degree apparent field of view observed through the Mark 45 are comparable to the B&L Mark 28 Mod 0, SARD Mark XLIV, and most other U.S. 7x 50s. The Mark 45 were issued with a Hood hard rubber carry case, and with nylon carry straps for the binocular and for the case.

The differences between the Mark 45 and others of this era are in their mechanics. Among those who appreciate the aesthetics of optical instruments, the Mark 45 Mod. 0 binocular is just about the sexiest looking 7x 50 military binocular ever made; it’s streamlined form is possible because the body is manufactured of drawn aluminum. This is a more costly manufacturing process than casting, but one that results in a slimmer profile and with lighter weight yet with strength similar to that of castings. Interesting mechanical differences include the carry strap loop of the Mark 45, each is machined from a solid block with a slot for the carry strap and with an elongated oval form precisely fit to match the curve of prism housing. The strap loops of most other hand-held binoculars of this era are more of a rectangular form.

Left: Hayward Mark 45 Mod. 0 binocular with provided nylon carry strap, note the form fitting machined strap loops and the prominent coated optics warning label on left prism cover (102,160 bytes).

Each side of general purpose 7x 50 models incorporate two prisms attached to a supporting Prism Plate (termed Cluster), these are bolted to the body casting. The prisms supports of the Mark 45 (and of the Bausch & Lomb Mark 41, and SARD Mark 43 too) differ from other U.S. military binoculars of this era in that they are affixed to a Prism Plate, that Cluster is affixed by three Prism Posts to a support plate and that assembly is attached to the rubber gasketed eyepiece and prism cover assembly. This arrangement increases resistance of the prisms to fracturing, or the shifting of their alignment (collimation) from an impact or shock. The Mark 45 hinge axle is a ratchet type for adjustment of tension that differs from conventional models in the way in which tension is exerted, while the forward end of the hinge differs from other 7x 50 models in that it incorporates a Zerk grease fitting. The Mark 45 weighs 2.89 lbs., while the SARD Mark XLIV weighs 2.92 lbs., and the B&L Mark 28 weighs 2.98 lbs. so these are all similar in that aspect.

There are some mentions that the Mark 45 may withstand greater water pressures or stress than most 7x 50 models, a U.S. Navy Manual from 1951 mentions this “is the most waterproof of all the binoculars. Designed for underwater service to withstand water pressure where the other binoculars will not, it is used on board submarines and by demolition teams”; to Company Seven eye’s this may have resulted from misinterpretations and some myths about the Mark 45. Interestingly enough, the Navy BUSHIPS (later NAVSHIPS) technical maintenance and repair manuals in our archives refer to the Mark 45 model as having to pass only the same waterproofness testing as that of other U.S. Navy 7x 50 binoculars. Since all general purpose Navy 7x 50's met the same water proofness testing standard, and as lookouts of many vessels were subjected to sea spray and waves, we at Company Seven suspect the association with submarines may have had more to do with the Mark 45’s superior resistance to failing from impact owing to it’s prisms housings mechanical arrangement. Submariners moved quickly when the General Quarters or dive alarms sounded, and in their haste to clear hatches (going below) a dangling binocular would be at risk to strike metal. Superior resistance to damage from impact could have made the Mark 45 better suited than most other 7x 50 binoculars for use by submarine crews. Of course eight decades later, we have not met anyone who was there who can confirm any of this, nor have we observed any evidence the Mark 45 were in fact ever issued to submarine or UDT service.

U.S. Navy Mark 45 binocular was also issued to allied forces, and some of these would be modified to better suit their missions. The Royal Australian Navy for example modified Mark 45’s by installing a desiccant chamber onto each prism housing, this to better deal with high humidity in their equatorial conditions.

As was the case with the Mark XLIV by SARD, the Mark 45 came off the production line so late in the war that by then most needs for binoculars of the fleet had been met; in August 1945 when the war ended many of these had not been issued and would remain in government warehouses. The U.S. Navy quickly cancelled many contracts for ships and materials that were then in production; in response many factories immediately laid off workers and staff to reduce overhead and transition to peace time. The Hayward company ended up with stocks of new Mark 45 binoculars, parts and HOOD cases, that would not be delivered to the U.S. government. Some of the inventory on hand at Hayward were completed and branded only with “HAYWARD” white inlaid lettering on the right prism cover and with the “7 x 50” on the left cover, and these were distributed to the civilian market; lacking a serial number it is difficult to estimate how many Hayward 7x 50’s were distributed outside the military.

Over the post-war years Mark 45 binoculars remained in service with the U.S. Navy for more than twenty years; warehoused old new stock, repair parts, and service remained available well into the Vietnam war era.

Company Seven has observed some Mark 45 with painted-on “HS-2” labeling, and also with an aircraft number. These Mark 45 were issued to the U.S. Navy Helicopter Anti-Submarine Squadron TWO (HS-2) established on 7 March 1952 in San Diego, then flying the Sikorsky HRS-2 (H-19 Chickasaw). In 1952, the squadron consisted of 258 enlisted and 39 officers to fly and maintain 17 aircraft. HS-2 (today HSC-12) remains the oldest rotary wing squadron in the U.S. Navy.

After the Korean War a number of used military issue Mark 45, and other models of 7x 50 too, became available as surplus. Decades after their production some Mark 45 binoculars were still being transferred to some U.S. government civilian agencies, these may bear property markings of organizations including: U.S. Fish & Wildlife Service, NASA, and NOAA (founded in 1970).

The production numbers of Mark 45 delivered to the Navy are similar to those of the SARD Mark XLIV, with fewer of both models completed than most other 7x 50’s. Today the Mark 45, like most other wartime production U.S. binoculars, are not particularly scarce though it requires some luck to find a Mark 45 that is not bound up by old grease, or beat to heck from hard use; used examples do tend to pop up for sale from time to time and some are in good to near new condition.

Owing to some differences and comparatively scarce parts availability, servicing the Mark 45 can be a bit more complicated than most others. Lacking specific tools, documentation and training no amateur should attempt to disassemble and clean or repair any of these binoculars, that is if they ever hope to use them again.

The SARD 7x50 Mark XLIV Binocular:

We have observed Mark XLIV binoculars packing cartons with stamped U.S. Navy acceptance dates and with their

Above at Left: U.S. Navy Quartermaster property acceptance stamp of this era, this on the packing carton of our SARD 7x50 Mark XLIV Mod. 0 binocular (7,203 bytes).

This binocular, Serial Number 403424, survived seventy-plus years in very much as new condition because it remained packaged within it’s factory issued carrying case, and this was well packed within the original outer carton; none other has come to our attention in this pristine condition. However, we have reports of SARD Mark XLIV Mod. 0 binoculars having been completed so late in the war that they were never issued because by then the demands of the fleet had pretty much been met by other production. The amount of new government property left unused at the end of the war is one of the indicators that the victories in the war by the United States were in some large measure attributable to our capacity to produce even more men and material than were necessary to win the war.

Soon after the end of the war the U.S. government made efforts to consolidate inventory, to cut down on fielded lower production Mark and Mod models of all kinds of equipment in order to simplify postwar parts and service support requirements. The U.S. Navy contacted civilians who early in the war had loaned their binocular (explained earlier in this article) to either return or replace these. In those instances where the owner’s binocular were lost, they were provided with replacement U.S. Navy new binoculars allocated from stock and these included the SARD Mark XLIV Mod. 0.

Characteristics: the Mark XLIV were the last assigned model version of 7x 50 binocular that were designed and manufactured during World War II specifically for assignment to U.S. Navy surface ships. This is not to say that some of these might not have found there way into submarine, or for use by other services (USMC, Naval or Army aviation, etc.).

The left prism cover bears the SARD binocular logo and manufacturer’s information. The right prism cover bears the information identifying the contracting agency, the model and variant designation, then the circle N symbol Ⓝ for number followed by the binocular’s serial number and year of the contract. The engraved information of our Mark XLIV, SN 403424 for example, is shown below:

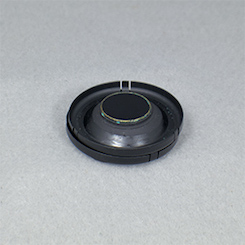

The lenses and prisms of all Mark XLIV binoculars that were produced incorporate the Magnesium-Fluoride treatment explained above, these coatings provide a brighter image than older uncoated models and with better clarity and contrast particularly in adverse seeing conditions: glare from sun or other off-axis bright lights, dusk or dawn, etc. The left side prism housing cover of this Mark XLIV Mod. 0 bears the factory stick-on warning label with yellow lettering THIS INSTRUMENT HAS “COATED OPTICS” CLEAN LENSES CAREFULLY. Some earlier production Mark XLIV Mod. 0 may have this applied to the bridge post, though this could be marred when the binocular is attached onto certain types of support brackets that grip this post. The warning label, all likely sourced from the same printer, were provided to other binocular makers of this era.

The Magnesium-Fluoride coated prism clusters are mounted onto a support shelf, that rests on lugs cast into the binocular body prisms housings. The body of the Mark XLIV is of cast aluminum, other components including the hinge brackets and the hinge post having been stamped or machined; construction components are nonferrous so that the binocular will not distort a compass. The hinge is substantially constructed with a precision machined post ½ inch in diameter. The resulting weight of 2.915 lbs. is not that far off from that of the B&L Mark 28 at 2.976 lbs.

The Mark XLIV stands 7-7/16 inches tall, with a typical width of about 7-¾ inches depending on IP spacing. The binocular feels good in the hands in terms of the fit of it’s castings profile as well as in terms of weight; that 2 lbs. 10.8 oz. construction reassures the user that this is not cheaply constructed. As these were designed then being produced for actual “your life may depend on this” kind of use, the focus was on performance and reliability.

In a move to standardize interchangeability of accessories, most makers of U.S. Navy general purpose binoculars adopted these same eyecups. Indeed most eyepieces and eyecups were interchangeable between many Mark and Mod binocular models. The eyecups of the Mark XLIV binocular too are made to accommodate snap-on Neutral Density filters, dark green tinted glass held in a metal housing with three flexible tabs; these filters cut glare and reduce fatigue over long periods on watch during the day for example. Some binocular sets included these and or polarizing filters, the binocular carry case typically incorporating a pouch inside the lid of the case made to accept the filters.

The eyecups can be removed by threading them off and this allows other interface rings to be attaching in place of the eyecup to accept optional polarizing filters, flexible rubber winged eye guards, or for extended observing sessions an entire padded face rest or Baker shield.

The Mark XLIV binocular eye lens clear diameter is 15.5mm, and the eye relief is an uncommonly generous 16.8mm; we at Company Seven measured this just to be sure. So given the large 7.1mm diameter Exit Pupil of 7x 50 binoculars that makes them easy to hold aligned to the eyes, and the generous eye relief if the Mark XLIV we can imagine some sailor (more likely an officer) being grateful to have this SARD with which to pass the time on duty.

Standards: since life and death could depend on these binoculars, great effort and expense were paid to insure they provided every optical edge, are durable, resistant to shock, and water resistant. The Navy required these and other similar general purpose 7x 50 binoculars to pass several tests including:

The Case And Packing: most handheld binoculars made for the civilian and military markets were similarly equipped with a set of accessories including: carry case, a case carry strap, and an adjustable length carry strap for the binocular. The case and straps accompanying most binoculars were made with either a hinged lid or one attached by a flexible flap of leather. The binocular slipped into the carrying case eyepieces end first, the prism housings bearing the load by resting on support blocks built in at either side of the case floor. The lid of a case might have provisions for storing accessories such as neutral density filters, umbral lenses, or polarizing filters.

Binoculars produced for the military during the early years of the war were furnished with a hard leather case and straps, many completed later were issued from the factory with a hard synthetic case and straps. Those cases made of molded synthetics that at first glance would seem to be made of a hard plastic, and these were accompanied by flexible nylon straps that could survive the heat and humidity of the Pacific and other tropics better than leather. These cases shed rain, are essentially maintenance free, and weigh less than a leather case. The molded rubber cases were also less costly to fabricate than the sewn leather cases. Some companies contracted to provide binoculars had the in-house manufacturing capability to produce the accessories, including leather cases, but setting up a new production line simply to mold cases of rubber was not practical and so these cases were contracted. So the largest scale binocular models manufactured by B&L, Spencer, and SARD transitioned from leather to the contracted hard rubber cases. Surprisingly, the comparatively modestly produced U.S. Naval Gun Factory Mark 37 were also issued with a taller Hood hard rubber case; we speculate that when conceived they may have envisioned manufacturing greater numbers of this model and that would have justified tooling to make the longer case. However, some models of binocular (including B&L Mark 21, B&L Mark 24, B&L Mark 41, SARD Mark 21, SARD Mark 43, etc.) were issued with a fitted leather case throughout the war years.

Some cases made by Hood for a binocular will bear a manufacturer logo, these include cases made for Bausch & Lomb, for the Spencer where their company logo is embossed atop thec case lid. However, all cases will still bear the HOOD logo, and case model designation (B3, B6, B12 for example) embossed at the exterior bottom panel of the case. The several different cases made to accommodate a 7x 50 binocular may at first glance appear identical but there can be subtle differences; for example a case made for a Bu.AERO binocular might need extra space below the lid to avoid compressing the winged rubber eyecups, and to accommodate the longer eyepiece and filter barrels, so Hood made provisions to fit these. Of course, after deployment to the field all bets were off as we are certain the carry cases and various binoculars often became mixed up.

Cases initially provided by Square D with their binoculars had been made of leather, with the SARD logo was embossed on the exterior of the case lid. The first few thousand or so of the SARD Mark XLIV binoculars delivered to the U.S. Navy were issued with the flap lid leather case, and carrying straps. However, later in 1944 Square D transitioned the Mark XLIV case from leather to the hard black rubber, this provided with flexible adjustable length black nylon straps. The set provided with our Mark XLIV is the molded case manufactured by the Hood Rubber Products Company, this case weighs 1 lb. 15 oz. The Hood case employs a flexible rubber rolled loop to fasten the lid to the case, this can fasten the cased onto a belt or a wall hook. In our seventy-two year old example the loop has become quite stiff, so it takes some careful effort to pull back the lid and hold it open while accessing the binocular compartment. The lid is secured by a flexible strap that is permanently attached to the case lid flap, this strap spans down the case front and the slotted end of the strap is fastened onto a brass post at the bottom of the case. Near that post is the Hood factory logo and stamp B6. We have observed another Mark XLIV binocular with a case stamped B3, but so many years later it is difficult to know the meaning of the B codes, or to know if the B3 case was provided with the binocular when new or added later.

After the war was won, the 7x 50 binoculars marketed by Square D Company’s Kollsman Instrument Division for the civilian market resumed being furnished with a hard leather case and straps.

The SARD Mark XLIV were provided to the Navy with a pack of desiccant to absorb moisture, both stored in the carry case. The case was wrapped in a brown packing paper and set into the packing carton 11 x 10-¼ x 6-¼inches tall. The case and binocular carry straps were each strap was rolled and the set placed into a manilla envelope (return addressed from Square D, 36-30 Lawrence Street, in Flushing), this was fastened closed and set into the packing carton. The carton was sealed, the Serial Number hand written on the label of the carton. The white paint of the label has mostly flaked away, while the two tones of blue remain perfectly intact. The prominent COATED stamp is also intact.

This carton shows signs at one corner and on the top of having been wet, those and some green oxidation of the carrying case fasteners give that away. Otherwise the carton is in great condition remaining ready to be closed, taped and sent off to war.

Images Of Our Mark XLIV:

Background And Postscript:

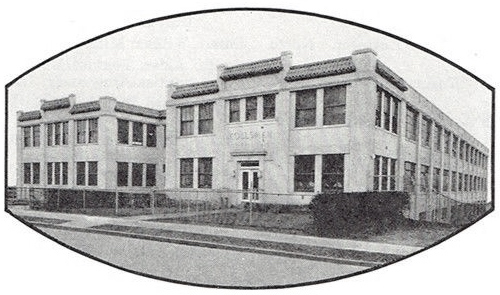

Right: North and west sides of the Square D Company’s Kollsman Instrument Division factory in Flushing where all or parts of our exhibited SARD 7x50 Mark XLIV Mod. 0 binocular were made.

Some factory locations, such as the 3.34 acres facility operated since July 1942 by Kollsman Instrument Division, of Square D Corp. in Binghamton, New York were owned by the US Government. Having been acquired through the Defense Plant Corp. here Kollsman manufactured optics for the U.S. Navy. The location of this factory was about halfway from Long Island to Bausch & Lomb in Rochester, NY. However, by August 1944 this Binghamton facility was declared surplus to the war effort; the buildings and land were sold for then present day replacement cost less depreciation to General Aniline & Film Corp.

Kollsman Instrument Company, Inc. was founded in 1928 by Paul Kollsman (1900-1982), a German engineer who had emigrated to the USA in 1923. Prior to, during, and after the war Kollsman was a highly regarded company. In 1928 Mr. Kollsman established his company in a Brooklyn attic, he was then a one-man company. Kollsman first came to prominence for developing the precision aircraft altimeter, it was his second more refined version that debuted on 24 September 1929 at Mitchell Field, Long Island in the first instrument only flight by then Army Lieutenant James Doolittle. By 1932 Kollsman Instrument employed 19 people. E. Otto Kollman (1901-1942), credited by his older brother as a co-founder, rose to become the company Treasurer and Comptroller until retiring in 1940. Kollsman patented hundreds of innovations that went into their manufacturing of aircraft flight management instruments including: Air Speed Indicators, Altimeters, Compasses, Engine gauges, Tachometers and much more. Kollsman Instrument became one of the two largest dedicated developers and manufacturers in their field.

Left: Kollsman Instrument Division headquarters and factory at 8008 45th Avenue, Elmhurst, Queens, New York.

The nearby personnel and equipment of the recently acquired Emmerich Optical Division were absorbed into the Kollsman Instrument Division, becoming Kollsman Instrument Optical Department. Bausch & Lomb licensed designs and assisted Kollsman to gear up for the production of binoculars. Given their expertise in the manufacture of precision instruments and the resources of Emmerich too, it was not a stretch for them to produce binoculars; it would be employees of Kollsman and of Emmerich that manufactured the binoculars that bore the SARD trade name and Square D Company labeling.

Kollsman Instrument Co. too had hired learnership employees, paid to learn and gain experience in programs planned to span about two and one half years. After Pearl Harbor, the ramping up of manufacturing resulted in Kollsman announcing in January 1942 they were abandoning their learnership program so they could devote all their machinery and equipment to production to operate 24 hours per day and 7 days per week. To support the round the clock production by 1943 employment at Kollsman topped 5,000 people, these operating in several facilities that had expanded to encompass some 440,000 square feet. The factory on 48th Street in Flushing bore “Kollsman Instrument Optical Department” name, prominently visible from the adjoining railroad tracks. This also explains how these may bear the origin of Elmhurst or Flushing, New York.

By 1945 the joint War Department (Army) and Navy Department Board for Production Awards awarded “E” with three stars, their Excellence in Quality award, for contributions to the defeat of the Axis Powers to Square D Co., Kollsman Instrument Division, Elmhurst, Long Island facility. The Board for Production Awards also awarded “E” with two stars to Square D Co., Kollsman Instrument Division, Flushing Plant, Flushing, where optical instruments were produced. The awards were earned by only about five percent of war production plants in the US, about half employed less than 500 employees.

After World War II Square D resumed normal operations organized around four divisions including Kollsman Instrument Division in Elmhurst, all doing well in manufacturing for all that new construction that followed. Square D even expanded overseas in 1946 acquiring all stock in Square D Canada and setting up new operations first into Europe, then to Asia and South Africa. In 1991 Groupe Schneider S.A., a French electrical equipment company, acquired Square D in a takeover that provided both companies access to larger distribution channels. Square D continues to operate as a subsidiary of Schneider. We expect few people working at Square D today will have any sense of the company’s contributions in World War II.

Military Binoculars Post War a number of these well proven binocular models continued in production to the end of the war. Soon after World War II ended many military binoculars and spare new parts too were retained in military warehouse stocks, though many more were declared surplus and discarded or made available to the civilian market.

The surrender of Germany in May 1945 resulted in many troops being transferred out of the European Theatre of Operations (ETO), while logistics and production adjusted to focus on the battles to be fought in the Pacific theatre. Allied leadership there had pondered the casualties and the time it had taken to capture just the eight square mile island of Iwo Jima: more than one month and a cost to the United States of 28,857 casualties (killed, wounded or missing), plus an estimated loss to Japan of about 18,000 men killed. The next stop was Okinawa and that battle, from April 1 to June 22, resulted in some 49,151 American casualties (killed, wounded or missing), plus about 33,000 non-battle casualties. There were more than 78,000 Japanese military casualties (almost all there were killed), and approximately 149,600 Okinawan civilians killed or wounded or missing. As the allies neared Japan the resistance intensified while casualties mounted.

At the fall of Okinawa the allies were implementing Operation Downfall. That had some 38 United States Army and Marine combat divisions, with the largest Navy and Air Force ever, all heading towards southern Japan for landings in November 1945. Another 70 divisions were to be transferred from Europe. There would also be allied forces (United Kingdom, Australia, etc.) involved. The Japanese military leadership anticipated this and were already implementing Operation Ketsugō (決号作戦), plans for homeland defense. It was not unreasonable to consider how landings on the Japanese main islands, occupying and pacifying them would likely extend the Pacific war well into 1947, and cost an estimated one million allied casualties plus many more Japanese killed or wounded.

However, the atom bombs dropped on Hiroshima and then on Nagasaki, with some 200,000 or more casualties over time, resulted in a hasty end of the war. The atomic bomb and the surrender of Japan in August 1945 had taken the American public including many manufacturers too by surprise. As Japan surrendered manufacturers found themselves with a surplus of employees (many plants were still operating shifts of workers 24 hours a day and 7 days a week), machinery, factory space, and this included buildings full of new binocular parts.

It would take some time for the men at arms to be gradually discharged, return to civilian life and create demand for new consumer goods.

Many World War II era military-issued binoculars were retained in active service or in reserve by the U.S. government and civil defense agencies, though the variety of Marks supported with parts and maintenance was reduced to streamline logistics. Many were warehoused until needed again, many being issued to troops fighting the Korean conflict. By 1950 what SARD 7x50 Mark XLIV binoculars had been issued during World War II were phased out as they came in for repair or service, any new spare stock and repair parts specific to the Mark XLIV were declared surplus. Through the 1950’s the Navy still employed the Mark 28 Mod 0, Mark 32 Mod 7, Mark 39 Mod 1, and the Mark 45 Mod 0; several of these World War II veterans were employed by Uncle Sam even as late as in Vietnam. Throughout the following several decades old stocks of these World War II era binoculars continued to pop up for sale on the market in new or factory/government refurbished condition. To this day many of these continue to provide boaters and amateur astronomers with fine performance, excellent value, and great durability. The World War II production U.S. made binoculars are not particularly scarce, and many remain in use, but it is rarer and rarer to find one in original truly excellent used or like new condition.

After the war Kollsman Instrument continued production of aircraft instruments for the military and for commercial aircraft makers, but they also expanded into the booming civil aviation markets with their more economical Scout line of instruments. Kollsman also dabbled in the manufacture and sales of optics, including binoculars, for the consumer market. Im part they were trying to sell off stocks of wartime production optics and retain skilled talent.

Some of the remaining inventory originally intended for Uncle Sam were assembled but without military markings and instead with civilian market labeling. Soon after the war new 7x 50 binoculars originally designed for the military were again coming off the assembly line bearing the SARD trade mark and either “PRODUCT OF SQUARE D CORPORATION FLUSHING NEW YORK KOLLSMAN INSTRUMENT DIVISION”, or “KOLLSMAN INSTRUMENT CORPORATION ELMHURST NEW YORK”, or the less common “KOLLSMAN INSTRUMENT DIVISION OF SQUARE D COMPANY ELMHURST NEW YORK” came onto the consumer market.

Left: Kollsman Instrument produced SARD binocular components were acquired by Edmund Scientific, then assembled and marketed as their 7x 50 binocular.

As manufacturers adjusted production and facilities to a post-war economy, many cases full of new binoculars and parts were simply discarded to make space. Some companies exited the binocular business, having no desire to keep paying for space to store items they could not sell. What efforts the remaining manufacturers made to market to a slowly growing consumer segment was met with competition from companies selling government surplus of the same product at a fraction of the cost. By 1946 one could buy new stock U.S. government Bausch & Lomb 7x 50 binocular bearing the Mark 28 Mod. 0 designation being sold as surplus for tens of dollars. The sale of war surplus continued for years and helped spawn some companies including Edmund of Barrington, New Jersey.

Some wartime products remained in production and would be marketed by the manufacturers directly to the consumer well into the 1950s. For example a “7x 50 MM, GOVERNMENT, BINOCULAR, MARK 28, MOD. 0”, in the original factory sealed packaging of the collection at Company Seven also lists the item as made by Bausch & Lomb, and with their Catalog No. 61-21-58-05. Late 1945 Bausch & Lomb advertisements, and their consumer catalogs up to at least 1950, show their identical production 7x 50 individual focus binocular, based on their Mark 28 and clearly pointing out it’s wartime heritage, but rebranded for the consumer market as their Catalog No. 61-21-58-05, indicating the binocular with case, selling for $162.00 plus excise tax.

Square D advertised their 7x 50 binocular as the SARD 7x 50 Marine Binocular, and also as “Night Glasses”. They promoted these as fully coated, and they were sold complete with leather case and carry strap. From soon after the war and at least into November 1950 this set was sold for $165.00 plus 20% Federal Excise Tax amounting to $198.00.

Unfortunately, among the adjustments made by manufacturers was the discontinuation of their most remarkable binoculars. So both the SARD “Mark 43 6x 42 Wide Angle”, and the Bausch & Lomb “Mark 41 7x 50 Wide Angle” binoculars were discontinued. No other company sought to acquire the castings, or rights to the designs in order to continue producing such costly items that could not survive in the consumer arena. Their high cost delivered commensurate life-saving performance that was well-justified for an immense wartime government. However, in peacetime their bulk, comparatively heavy weight and high cost could not garner sales in enough numbers to justify keeping them in production.

New SARD-branded Consumer Binoculars: Kollsman Instrument set up a wholesale distribution chain so the SARD binoculars could be purchased at retail stores including the R.H. Macy & Co.. To support their retailers SARD binoculars were advertised in boating, outdoor and other publications. To establish even more of a presence in the marketplace Kollsman Instrument negotiated with Abercrombie & Fitch Co. of New York, a showroom and catalog based sporting goods company whose flagship store was on Madison Avenue, to produce both the 7x 50, and late in 1946 the new

Right: advertisement bearing the SARD trade name for Kollsman Instrument “SARD Sportsman” compact 6x 20 prismatic binocular, from the 18 December 1948 issue of The New Yorker Magazine. Soon after the war these were advertised as selling for $198.00; consider that was about 5% of an average annual income while an average monthly house payment was about $80.00.