Recollections of the NASA STS-61 First Hubble Space Telescope Servicing Mission

It was fifteen years after working on this project when enough distance had passed to see it from another perspective and write this article. Most of the people mentioned in this team or those who worked on other parts of the mission should have seen enough time pass so that they too might smile and find something good to recall in this article. So before these memories are forgot this article recalls the brilliant engineers, our team leaders, and those NASA management people who were critical parts of this project on the ground. The mission earned the 1993 Collier Trophy, and was the mission that many people say saved NASA and the space program.

"The public views NASA through a series of spectacular images and video of launches and space activities, and articles abound about the astronauts too. But they rarely see what goes on behind the scenes of a NASA mission. While rarely life threatening as a launch or space walk may be, it is the activities on Earth that will most likely spell success or failure for a mission...the astronauts realize this, now if only all management and politicians did so too."

![]() Introduction: Background and Why The Mission Was Necessary

Introduction: Background and Why The Mission Was Necessary

The NASA Hubble Space Telescope (HST) named after the astronomer Edwin P. Hubble (1889-1953), is a remarkable space-based observatory. At it's core is a 2.4 m (94 in) diameter mirror, in a 43-foot (13 meter) long Ritchey-Chrétien reflecting telescope. This is equipped with a selection of instruments for scientific research in the Optical, ultraviolet, and near-infrared.

The NASA Hubble Space Telescope (HST) named after the astronomer Edwin P. Hubble (1889-1953), is a remarkable space-based observatory. At it's core is a 2.4 m (94 in) diameter mirror, in a 43-foot (13 meter) long Ritchey-Chrétien reflecting telescope. This is equipped with a selection of instruments for scientific research in the Optical, ultraviolet, and near-infrared.

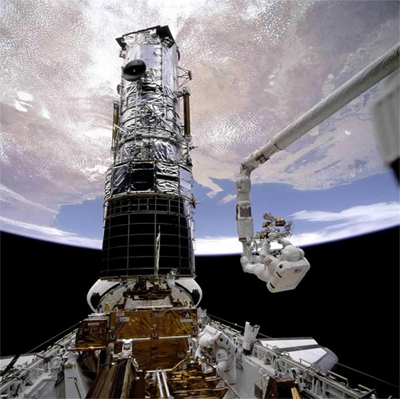

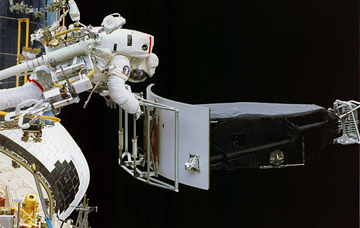

Right: 8 Dec 1993, Hubble Space Telescope berthed in Shuttle Endeavor's payload bay with Astronaut Story Musgrave (127,751 bytes).

Click on image to see striking enlarged view (625,039 bytes).

The concept of an observatory in space was first described in 1923 by Hermann Oberth (b. 25 Jun 1894, d. 28 Dec. 1989). Oberth was an Austro-Hungarian born Doctoral candidate who published Die Rakete zu den Planetenräumen (The Rocket to Planetary Space) in which suggested a telescope could go into space aboard a rocket. Oberth would become a well regarded pioneering German rocket scientist whose pupils included Dr. Wernher von Braun; both would later work in the USA on our space programs. The idea of a telescope in space came up again in a paper published in 1946 by accomplished astrophysicist Lyman Spitzer Jr. (b. 26 Jun 1914, d. 31 Mar 1997). Part of Spitzer's rationale for this included the fact that an instrument placed above Earth's atmosphere would not only be freed of atmospheric transparency limitations in the visual spectrum, but that it could be a platform to work in areas of the electromagnetic spectrum that are blocked by Earth's atmosphere and magnetosphere. By 1962 a mission more like the Hubble was suggested in 1962, Spitzer was among the advocates for space borne platforms that in time would fly including the Copernicus and the Orbiting Astronomical Observatory (OAO) satellites. With his track record of high achievement, Spitzer was among those who persuaded Congress in 1969 to approve the idea of building a large space telescope.

NASA began preliminary studies in 1975, and by the Hubble Space Telescope project was funded by Congress and constructed between 1977 and 1985. The fabrication of the instrument was managed by NASA Marshall Space Flight Center although the critical mirror optics were made by Perkin-Elmer Corporation, Danbury, Connecticut between 1979 until completed in late 1981. The launch was postponed after the tragic loss on 28 January 1986 of Space Shuttle Challenger and subsequent program suspension, so Hubble was stored and maintained by Lockheed in California. The HST was finally launched on 24 April 1990 aboard the Space Shuttle Discovery on "Space Transportation System Mission 31" (STS-31). For more details about Hubble history we recommend reading the Wikipedia article "Hubble Space Telescope" at "http://en.wikipedia.org/wiki/Hubble_Space_Telescope".

Soon after the launch and release of the HST into orbit some NASA scientists began to suspect something was amiss with the telescope since the image data being received were poor appearing out of focs. It was about this time that Dr. H. John Wood of NASA Goddard Space Flight Center, Greenbelt, MD invited Martin Cohen (formerly of NASA GSFC) to visit him at the new Space Telescope Operations Control Center (STOCC) at Goddard, also known less formally as Mission Control or Building 13. Dr. Wood is a brilliant optical engineer, an amateur and professional astronomer, an educator who render complex subjects understandable, and is as unpretentious as he is gifted. Dr. Wood mentioned some concerns about the images coming in from Hubble, they considered the possible reasons for the anomalies. Mr. Cohen recalls developing a sinking sensation over the course of that discussion as the likelihood of a serious problem with HST became apparent.

Some days after my meeting with Dr. Wood at NASA-GSFC the news of the flaw was announced to the public by NASA Headquarters. On 27 June 1990, some two months after HST was placed in orbit, Dr. Edward Weiler (Director of the Astronomical Search for Origins Program at NASA Headquarters and Chief Scientist for the Hubble Space Telescope) explained in clear terms "It's broken and we're going to have to fix it". Even with its problems the Hubble Space Telescope still provided some advantages over ground-based telescopes even if the data it produced fell well short of what it was intended to do, but what if could do was just not worth the full price tag paid by the American taxpayer.

Some days after my meeting with Dr. Wood at NASA-GSFC the news of the flaw was announced to the public by NASA Headquarters. On 27 June 1990, some two months after HST was placed in orbit, Dr. Edward Weiler (Director of the Astronomical Search for Origins Program at NASA Headquarters and Chief Scientist for the Hubble Space Telescope) explained in clear terms "It's broken and we're going to have to fix it". Even with its problems the Hubble Space Telescope still provided some advantages over ground-based telescopes even if the data it produced fell well short of what it was intended to do, but what if could do was just not worth the full price tag paid by the American taxpayer.

Left: illustration of the Hubble Space Telescope by professional illustrator Daniel Kirk (73,999 bytes).

Image © Daniel Kirk 1990, all rights reserved. Permission granted to Company Seven directly by Mr. Kirk to show his artwork here.

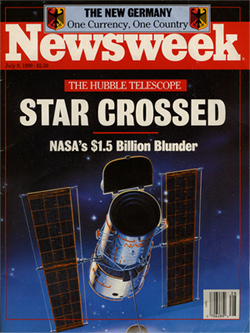

As word spread of the problems into the public the flawed space telescope became fodder for comedians. Even the most staunch fans of the space program including Johnny Carson, host of The Tonight Show, could not resist having some fun at NASA's expense. The news media and those in political circles criticized NASA, while defenders of NASA pointed fingers elsewhere, and so on. Many of us who were somehow involved with space either as an amateur or professional will never forget the impact of seeing the July 9, 1990 Newsweek magazine cover on the news stands bearing the title "Star Crossed: NASA's $1.5 Billion Blunder" - this was one of those rare instances where the news coverage of an event was so indicting that it actually became a part of the history of that event.

A panel commission was appointed to determine what went wrong with the construction of the Hubble and how best to remedy it, this was headed by Lew Allen then the director of the Jet Propulsion Laboratory in California. Working to evaluate a patient that is not conveniently located on Earth to determine the remedy forced the NASA scientists to work backwards to reconstruct what might have gone wrong. This was done by analyzing the images coming from Hubble and poring through the records that are created at all steps of fabrication. Dr. H. John Wood led the team that successfully determined the actual optical figure (or prescription so to speak) of the telescope, and he would later head NASA's effort to develop the corrective optics. The problem was determined to have occurred during the fabrication of the Primary Mirror at Perkin-Elmer. In The Hubble Space Telescope Optical Systems Failure Report published by NASA in November 1990 the Allen Commission explained the differences between the mirror system of the HST as it was delivered from what was called for in the specifications. The Primary Mirror was flawed by having been figured (ground and polished) at its outer radius too flat, this was wrong only by a depth of 2.2 µm; consider human European hair is typically between 57 to 90 microns in diameter. This caused spherical aberration, an optical problem that resulted in images that were fuzzy or not clear and with light scattered about. While the Perkin-Elmer employees and their management took a lashing, NASA management also bore criticism for their lax oversight of their contractor Perkin-Elmer. But no one prominently mentioned the interference by U.S. Department of Defense in reducing the access to the Perkin-Elmer facility by NASA inspectors (read the House Appropriations Committee work investigating this is 1983), or the efforts to save money by NASA management since Congress and the Executive demanded a NASA that did more with less. So if accountability really starts at the top, then...

Right: Astronomer and optical engineer Dr. H. John Wood, NASA-GSFC (127,751 bytes).

For this effort NASA put together the "A Team" of astronauts comprised of astronauts each with anywhere from two to five missions accomplished. Furthermore, NASA Headquarters shifted control of the planned "Servicing Mission 1" or STS-61 to NASA Goddard Space Center with much of the work also being done at the Caltech managed NASA Jet Propulsion Laboratory, La Ca–ada Flintridge, California and by Ball Aerospace & Technologies Corp. with facilities in states including Colorado and Virginia. Dr. H. John Wood at NASA Goddard Space Flight Center oversaw the development of the necessary corrective optics which was successfully completed in time for this mission. So in addition to other previously planned work on Hubble involving new Solar Panel arrays, Rate Sensing Units (RSUs), two Electronic Control Units, and fuse plugs, the work would include incorporating corrective optics into two components:

-

1. Corrective Optics Space Telescope Axial Replacement (COSTAR) displaced the Hubble's High Speed Photometer (HSP)

2. Wide Field and Planetary Camera 2 (WFPC2) replacing Hubble's original Wide Field and Planetary Camera (WF/PC)

In the early 1990's we recall some discussions with NASA personnel about Company Seven providing some support in this mission. But this was politically a very hot potato, suited only for those who were the best in their respective areas, and Company Seven felt we should not become involved. We learned later that a NASA contractor constructed one of the instruments that we where discussing; they charged NASA about forty (40) times the cost that we would have.

The construction of WFPC2 with changes planned to accommodate corrective optics was led by Prof. J. A. Westphal, Principal Investigator (PI) of the California Institute of Technology; it was he who had also directed development and construction of WF/PC-1. The WFPC2 instrument was built at the Jet Propulsion Laboratory then in June 1993 it was moved to NASA Goddard Space Flight Center into the world's largest clean room the High Bay Clean Room, a 1.3 million cubic foot facility, while work was finishing up on COSTAR too. This telephone booth shaped module was constructed to correct the deficiencies of the optical path due to the flawed shape of the mirror. Consisting of five pairs of very difficult to make corrective mirrors, these aspheres made by Tinsley were as small as a nickel coin. The mirrors were precisely placed in front of 1. Faint Object Camera, 2. the Faint Object Spectrograph and 3. the Goddard High Resolution Spectrograph.

At about the time NASA thought work was concluding on WFPC2 and as it was readied for delivery to NASA's John F. Kennedy Space Center, a curious article appeared in Aviation Week & Space Technology (nicknamed by some "Aviation Leak &..."). The article suggested there might be a problem with the focus of the WFPC2. Furthermore, the error likely exceeded the capability by Hubble to change focus; this would result in the images returning to Earth after the repair appearing worse than those before the repair! This came to the attention of Vice President Al Gore who then discussed it with President Bill Clinton. The President invited NASA Administrator Daniel S. Goldin to meet with him (immediately if not sooner no doubt) at the White House to discuss this article.

Keep it in mind that this was in a period when NASA had been working their way out of several mishaps including the Hubble problems, the tragic loss of Shuttle Challenger, and loss of several space craft. The Mars Climate Orbiter space probe went silent on 23 September as it descended to Mars causing yet another $330 million dollar loss (not counting investments in people and missions planned), all because a Lockheed Martin engineering team used English units of measurement while the NASA JPL team used the more conventional metric system for calculating a key spacecraft navigation operation. All the while, the Clinton Administration was lobbying in Congress for Space Station Freedom funding and funding for other NASA adventures. So the last thing the President wanted to hear is how a $1 billion dollar Hubble repair made things worse! Through the grapevine we came to learn something about President Clinton's temperament. NASA was given a simple alternative to either make the Hubble Repair Mission work on schedule and return beautiful pictures by the New Year, or face the prospect of a NASA dramatically altered in its form and capabilities soon after then. This motivated NASA to work in a manner with intensity and purpose not seen since the days of the early Apollo moon landing missions.

The deadline for the roll out of the WFPIC2 from Cape Canaveral to the KSC Shuttle Payload Integration Facility (SPIF) where it would be loaded into the Space Shuttle Endeavor was a Monday morning in October. If WFPIC2 were not moved to the SPIF by that date in October, then the scheduled rollout of the Shuttle on November 15 to the Launch Complex 39B and the planned launch date of 1 December would slip by. But NASA had to prove to the Administration that WFPIC2 was truly ready to fly before launch. An independent panel was put together to supervise NASA's work on this aspect of the repair mission. The Chairman of the panel was the head of one of the nations premier University optics programs. The NASA engineers and management would perform checks and double checks, gather data at every step, fix WFPC2 if needed. The NASA team had to have the work completed and their data and conclusions in the hands of the independent panel in time so they too could evaluate this. If the panel concluded things looked to have been accomplished properly, then they would report to the President and he in turn gave NASA the OK to launch. If the NASA team did not have its work done properly, or on time then the mission launch date would slip to beyond the desired date. And if the date slipped then besides having something else to explain, this delay would also cost of several extra millions of dollars. So there was real pressure from the top down to do this and to get it right.

![]() Our Involvement and Recollections

Our Involvement and Recollections

As Martin Cohen recalls:

"One Saturday morning I arrived at Company Seven to find a message from Dr. Wood mentioning he and a team were working in the High Bay Clean Room building at GSFC, and he asked me to return the call as soon as possible. I returned the call and he asked me to to provide an opinion regarding performing some optical focus tests, and whether or not Company Seven possessed hardware that might facilitate this kind of work. I offered to gather some items and meet him at GSFC that afternoon. Initially I did not ask, nor was I informed that this work involved Hubble WFPC2. The work seemed to be so intense, with the team members so focused on the task and somewhat secretive that I thought they might be working on some other type of work. Since the time was some few months away from the launch of the coming First Hubble Space Telescope Servicing Mission, I gathered work had been completed on Hubble and supposed Dr. Wood and the team were working on another project.

In time I became aware that this was the First Hubble Space Telescope Servicing Mission, and Company Seven formally participated as a contractor. The way by which I came to realize the nature of the task however was rather interesting. While working increasing hours at NASA Goddard time was a precious commodity, so even when we would take time off for a meal we tended stay very close to the office. One day we went to to have lunch at a sandwich shop in the shopping center just across the street from the GSFC main gate. As we chatted John's pager went off, he looked at it and commented "that must be (a reporter from a large newspaper), I bet my secretary gave him my pager number". A few minutes later the pager went off again, John looked and this time said "that's (another reporter from another big newspaper), I'm not losing my job by talking to him". At that moment the reality of Hubble sank in, and John suggested we will talk after we return to GSFC.

It was both unsettling and exciting to be working on this mission. Yet even as I worked on the task the news reports circulated as tens of millions of dollars in fines were being imposed on Perkin-Elmer for "non performance" with the original construction. NASA's reputation, and the future of anyone involved in this task were on the line. Company Seven gradually increased it's commitment so that this became the all consuming task working at several locations including the Goddard Space Flight Center High Bay Clean Room where the WFPC2 had been sent to from JPL. No contract for Company Seven to work on this task had been negotiated in advance, I had initially agreed only to help a friend. As Company Seven time and other expenses on the task mounted, Dr. Wood insisted I should submit an invoice for services, hardware, travel, etc. For a short time after realizing our work was on Hubble I was hesitant to put anything in writing. But as expenses incurred mounted I took his advice and summarized on a simple sheet of paper the receipts and log of time, then handed it over. I was so concerned about having any part in what appeared to be some 'renegade underground operation' that the billing for labor and other expenses was set at such a moderate rate (considering what other contractors Lockheed, etc. charged for engineers per day, etc.) that the low labor rates probably caused some eyebrows to furrow. Amazingly in a day or two a check arrived at Company Seven with full payment of these costs to date. And this was accompanied by the formal contract for Company Seven "In support of Prime Contract No. NAS5-5000; Flight Systems & Servicing (FS&S) Program".

One of the more interesting aspects is how the team developed the idea of employing a modified Questar QM-1 Long Distance Microscope, with optics precisely abberated to show astigmatic star images, to perform the final critical focus tests of the WFPC2 at Cape Canaveral. The evaluation of focus was performed by evaluating dim K spots (appearing like pin-point stars) within the WFPC2. This had to be performed while looking at these through the QM-1 with the human eye because there was no CCD camera in production at this time that had both the low light sensitivity and resolution to equal the eye of an astute observer. Understanding that we could get this wrong and miss something, this understanding weighed heavily upon all of us.

Right: at Cape Canaveral clean room is the Questar QM-1 Long Distance Microscope being readied in the support frame to perform final focus check of the WFPC2 (89,209 bytes).

Click on image to see enlarged view (240,894 bytes).

After the method was devised for performing the focus tests and adjustments, then the hardware and the WFPC2 were packaged securely moved by special tractor trailer to the secure hangar complex within Cape Canaveral Air Force Station adjacent to the NASA Kennedy Space Flight Center. I asked why move this to Florida to finish the work? And the reply was "safer from terrorism"; I sensed NASA was more concerned about terrorists from Capitol Hill and news people. By this time I thought my work was completed as the remainder of the team departed to Florida.

But a few days later, early on a Sunday morning I was telephoned by someone at NASA Headquarters who asked if I could catch a flight from National Airport to attend the afternoon team meeting at Cape Canaveral. I packed only an overnight kit and about five hours later found myself joining the team in the conference room for the afternoon staff/progress meeting. The core team physically working at Cape Canaveral on the WFPC2 was down to about a dozen NASA GSFC and JPL personnel with some support personnel. Before the meeting started we took our seats around the conference table, I casually made mention of my observation of how the team had been pared down to so few and that I was the only contractor remaining on the team. My comment was immediately answered by Dr. Steven Macenka, the team leader, who while reading through documents at the head of the table, and without looking up or missing a beat replied in his ominous eastern European accent "we will need someone to blame it on".

The work had seemed to involve increasing hours at GSFC, but once at Cape Canaveral the pace accellerated and the days grew longer. This work schedule culminated in days that commenced with staff meetings and status reports starting at 7:30 am, and concluded as late as midnight or even later at times! Even meal (and other) breaks were planned so that the work schedule was not impaired.

The better parts of several days at the Cape were spent in the large clean room, and we adapted to the requirements of this work. To enter the clean room one has to pass additional layers of security, and walk through a set of small rooms, these are layers or partitions keeping the clean room clean. In the first vestibule adhesive floor mats trap loose dirt from shoes. The next stop is a small glass box a little larger than a phone booth where we receive a forced-air shower. Dozens of air jets on the walls blow away loose debris from hair, skin and clothing. A green light indicates when it is safe to enter the last station, a larger area with lockers and benches. It is in this area where anyone intending to enter the clean room will don a sterile bodysuit (nicknamed "Bunny Suit"), head cover, two pair of rubber gloves (in case one layer tears), boots and a face mask; a tedious and meticulous process that can consume 10 to 15 minutes.

It was at times a surreal experience to be in the room after a long day, especially when the room lights were dimmed for some of our work. The feeling of being locked into an immense room with high air flow passing through its wall panel air filters, a room was as cool as a tomb but tolerable since the clean room clothes and gloves would otherwise leave us uncomfortably warm. It was easy to lose track of time and day if one did not look at the clocks. Anything entering the room (team members included) had to undergo a meticulous cleaning process in advance. The work to clean gear and parts entering the room was performed by highly skilled technicians in the antechamber of this large room; I wonder what they thought as our team leader had a Chess set processed into the room? He would play against other team members, stepping from the immediate work area to study the board for a moment or a minute then make his move and return to work. These were among the mental health techniques for a team stressed by immense engineering demands confronting them, complicated by the mounting pressures from the management and politicians who were pressing the team to succeed - but do so on a timetable. I recall several of us laying away from the work area but on the floor (it was clean after all) trying to rest or take a brief few minutes nap, when the team leader came by and commented "you look like a lined up row of body bags!".

NASA Headquarters had assigned a manager to oversee our work and report everything we did to the NASA Administrator. We understood that he was under immense pressure, he probably was convinced the fate of NASA was riding on the success or failure of this work. So he did what he could to help us with logistics, travel to meals, he arranged it so that those of us who could be spared for a short time were taken to the Kennedy Space Flight Center Static Test Road site to watch the launch of STS-58 with Space Shuttle Columbia. This launch finally went off on 18 October at 10:53 EDT. Columbia was the first shuttle in the fleet to orbit, but sadly was lost with all crew members on 1 February 2003. While we were working at the Cape the manager arranged for us to tour the KSC, visit the Shuttle Endeavor that would carry our payload, and tour other NASA and Cape Canaveral historic and interesting sites. OK, I know that by now you are wondering if I was getting paid money for working there too.

A revealing episode occurred one morning in the conference room. This mission was a complex matter, one that involved understanding clearly every aspect. It was necessary to quantify the properties and variables of every component so that the project engineers could predict their impact accurately. The plan developed at GSFC and at Cape Canaveral involved a lens set that I recommended for a critical test of the WFPC. This item was well known to me, it's approximate properties and how it would likely affect the light path. In order to determine it's exact properties I formulated a plan to perform as simple test with some items that could be sent to me from Company Seven in Maryland by Next Day Air. I discussed the idea with a colleague on the team Stuart who held a Ph.D. in optics, and we agreed to bring this up at the next morning staff meeting. That meeting was attended by the usual team and in the back of the room was a management representative from NASA H.Q. As my turn came to speak I explained the question that had come to mind and outlined the test method to derive the answer. The team listened and concurred. Then we discussed how we could fit this into the timetable and make it go more quickly. For example one fellow suggested opening a time slot in the clean room for the testing later that evening, while another suggested we could fly someone in that afternoon from Washington, D.C. with the parts needed; we were working as a team as had been the norm. The fellow from H.Q. then entered the discussion, he was concerned about whether or not this might set back our timetable. He asked was this really necessary at all? He looked to me and asked if I could provide an informed estimate, to which I replied "I prefer not to guess on any aspect of a $1 billion dollar effort, especially when I can give an accurate answer within a day or so of testing.". At this point the team leader intervened and "yes" that we would do the testing and work to minimize the impact of this procedure on the timetable. The manager said to the entire team there "I am just concerned that you guys are testing this thing to death, and it might run late". With that several of the team members spoke out expressing their annoyance with this pressure, Bill mentioning "we wouldn't be here if you guys had tested this thing to death the first time". By then the team leader appeared to have had enough of this interference, and he too expressed his opinion to the manager asking if the manager was now running this test, even insisting he would immediately inform NASA HQ of a change of leadership then leave Cape Canaveral and return to California with the manager left to take over the team. With that the manager agreed to withdraw and allow the team to do what they deemed best. But he made it clear with his last words and while sweeping his arm across all of us "Ok, we'll do it your way, but understand this, I write all your f_____g paychecks and this thing is rolling out...(on schedule)". Then he walked out of the room with the heavy conference room door slamming behind him. The room was silent, you really could hear a pin drop as we all looked across the table at each other in silence contemplating what we had just experienced. I appreciated the pressures that must have been on the manager and our team leader, but I realized then why the Hubble repair mission probably became necessary.

Right: M. Cohen of Company Seven in clean room protective "Bunny Suit" standing before the WFPC2. Image taken in the secure clean room at the Cape Canaveral Air Force Station as the WFPC2 was readied for roll-out in its transporter to the Shuttle Payload Integration Facility (SPIF) where the Space Shuttle Endeavor awaited (239,172 bytes).

Click on image to see enlarged view (879,105 bytes).

There are many stories to tell of the days on this project, but most of these are best not published. One interesting experience occurred because when I was called by NASA to travel to Cape Canaveral I arrived with only an overnight kit. As my stay with the team was extended from days into weeks, I bought a spare set of clothes and would turn one in to the laundry rotating on a daily basis. I tended to leave my room at the nearby Radisson Resort Hotel with the bed made, and just with shaver and personal kit along side the sink. Since I departed the room early in the mornings and I never took time for breakfast at the hotel, then returned very late, the hotel employees who observed the room appeared unused checked me out. One morning at about 3:00 am I returned from Cape Canaveral to find my room key did not work on the hotel room door. I jiggled the door handle and was amazed to hear someone in my room yelling wildly, then the door opened as a pistol from within was being drawn towards me! After a truly awkward moment I reasoned the room had been rented to this other person. After a few minutes of discussion with the armed occupant the hotel manager arrived and apologized profusely while promising to find another room for me. The manager explained to me that in Florida it was not uncommon, given the crime, to find honest people traveling with guns! Thinking I had a 7:30 am meeting to attend I was only interested in recovering my stored personal belongings and getting some sleep. The manager offered to me coupons for free meals, etc. however, throughout my stay there I never was able to make the time to use those free offers.

What I recall most fondly was the admiration and respect for the work and good humor of team members, all working under incredible pressures. There was always that concern "are we missing something?" after all we were here because someone else missed something. We occasionally joked about how the launch would probably go off by early December, and so while the Hubble settled in after the mission, we might all meet around Christmas or New Year at somewhere warm like Acapulco, Mexico to await the first images coming across the news papers. If the images were clear and sharp then we could return home otherwise, we would plan on a career of waiting tables in Mexico for the rest of our lives!

Another humorous episode started while we were working on the pie slice shaped WFPC2 in the Cape Canaveral clean room. A discussion started that revolved around the machining tolerances of the Hubble Telescope and the WPC2. The concern came up that these tolerances were so precise that there was a real risk that while sliding it into place the astronauts might bind the WFPC2 instrument into the Hubble telescope compartment opening and not be able to install it properly. Along the lines of this discussion I mentioned how at Company Seven when an instrument passes our quality control testing we affix an aluminum sticker onto it. Furthermore, I suggested that I would have to affix that C7 label onto the WFPC2 as part of our contractual obligation. Of course I was only joking then, but this joke would be back onto me some weeks later.

Another humorous episode started while we were working on the pie slice shaped WFPC2 in the Cape Canaveral clean room. A discussion started that revolved around the machining tolerances of the Hubble Telescope and the WPC2. The concern came up that these tolerances were so precise that there was a real risk that while sliding it into place the astronauts might bind the WFPC2 instrument into the Hubble telescope compartment opening and not be able to install it properly. Along the lines of this discussion I mentioned how at Company Seven when an instrument passes our quality control testing we affix an aluminum sticker onto it. Furthermore, I suggested that I would have to affix that C7 label onto the WFPC2 as part of our contractual obligation. Of course I was only joking then, but this joke would be back onto me some weeks later.

Right: 7 Dec 1993, Astronaut Jeffrey Hoffman removing the original WFPC 1 from the Hubble Space Telescope to make way for WFPC2 (151,981 bytes).

Click on image to see enlarged view (1,860,603 bytes).

After our work on the WFPC2 was completed at Cape Canaveral there was no celebration by our team. We still had to explain what we did, then await the results of our work being evaluated by the independent panel. Of course this climaxed on a Sunday and if we did not get it right then this left no margin for problems since the hoped for rollout of WPC2 had to happen by the following Monday morning at 4:15 am if the mission was to adhere to schedule. It was a strange feeling as though we were awaiting the grading of a Final Exam. And in time that grade came - 'A'. The word passed through our team that NASA HQ and the President had been informed the work done appeared correct, and STS-61 was go for launch.

After then it was business as usual but at a more relaxed rate. The mood was uncommonly sedate as we packed our gear over the next several days and returned home. Maybe we were too tired to be anything more than introspective. But we wold have to wait for nearly six weeks or so before we would learn if this immense NASA effort had redeemed the reputation of the agency, and whether or not we would be called to testify at Congressional hearings.

Above: Several core members of the test team with NASA supervisor and support members. Some are smiling so this must be after our work was completed.

Front left to right: Kevin Redmond, Bill Eichorn, Dr. Steven Macenka. Also pictured are Frank Ceppolina (rear right, in blue shirt) and Martin Cohen.

Image taken by Dr. James B. Breckinridge for C7 outside Rusty's Seafood & Oyster Bar in the city of Cape Canaveral, one of our frequent haunts. (133,874 bytes)

Click on image to see enlarged view. (375,560 bytes)

On 2 December 1993 at 4:26 am (within 0.019 seconds of schedule) the Space Shuttle Endeavor with the WFPC2 and COSTAR aboard launched and headed for Hubble. The launch had been delayed by one day due to the out of limit weather conditions at the Shuttle Landing Facility in the event of a Return To Launch Site (RTLS) abort contingency. I was relieved the launch went well, but most of us on the team that I spoke with then were not celebrating yet.

On the third day of the mission the team recovered the HST and it was accessible from Endeavor's payload bay. On mission days six into seven, the night of 6 December (Washington, D.C. time) the astronauts Hoffman and Musgrave were performing a space walk to remove the WFPC 1 and install the WFPC2 into the Hubble. This was completed by about 1:05 am on 7 December. It was about that time when I received a telephone call from one of my fellow NASA team members; I had not been watching the televised live coverage of the mission and his call woke me. He explained how the astronauts had run into a problem when maneuvering the WFPC2 into place due to some mechanical binding. He went on to explain the astronauts found a 'Company Seven' sticker (see image of one above left) affixed to the WFPC2, one that they were not equipped to remove, and this was preventing the WFPC2 from sliding into the Hubble thus causing them to scrub the install! He had me for just a moment before I realized that no, I never did attach that sticker at least that's my story and I am sticking with it.

- Mission: First Hubble Space Telescope Servicing Mission

- Space Shuttle: Endeavour

- Launch Pad: 39B

- Launch Weight: 250,314 pounds

- Payload Weight: 17,662 pounds

- Launched: December 2, 1993 4:26 a.m. EST

- Landing Site: Kennedy Space Center, Florida

- Landing: December 13, 1993, 12:26.25 a.m. EST

- Landing Weight: 211,210 pounds

- Runway: 33

- Rollout Distance: 7,922 feet

- Rollout Time: 53 seconds

- Revolutions (Orbits): 163

- Mission Duration: 10 days, 19 hours, 58 minutes, 37 seconds

- Orbit Altitude: 321 nautical miles

- Orbit Inclination: 28.45 degrees

- Miles Traveled: 4,433,772 miles

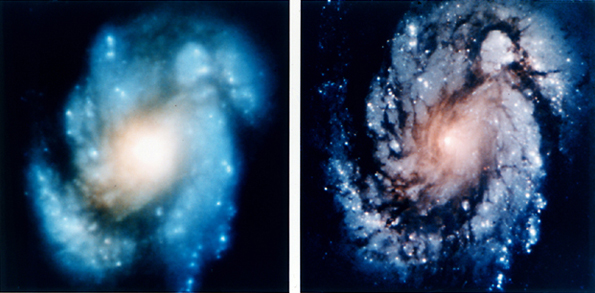

During a record five space walks on this mission amounting to 35 hours and 28 minutes, two teams of astronauts completed the first servicing (NASA never did use the term "repair") of the Hubble Space Telescope. In many instances the tasks were completed sooner than expected, and when a few contingencies arose then these were handled smoothly by the NASA team. HST was then boosted to a slightly higher orbit at 321 nautical miles (595 kilometers) on mission day eight. As we all now know, the thing worked and the spectacular images and good science returned from the Hubble tell the tale of success by the team members who built and repaired it. On 13 January 1994 NASA formally announced the mission, one of the most complicated and demanding in NASA history, had been a complete success as they released the first of many much sharper images to come from Hubble.

Above: comparison images of M100 Spiral Galaxy taken through Hubble Space Telescope. At left is an image taken by WF/PC 1 on

27 Nov. 1993 just before the STS-61 servicing mission (66,658 bytes). Above right is image taken through WFPC2 on 31 Dec. 1993

soon after completion of the First Hubble Space Telescope Servicing Mission (84,859 bytes).

Click on image to see enlarged view (1,860,603 bytes).

Afterwards there was much praise to go around, with receptions and meetings with the astronauts who performed the incredibly complex work of installing these modules in space. We were originally called into the task because NASA lacked the time to design and build sophisticated equipment to perform the focus testing and calibration of the WFPC2. With suggestions by Dr. Wood and team members too the obstacles were overcome and solutions were found. After the mission was completed and the resounding success of the effort became apparent then there were many people at NASA and contractors to thank. Company Seven was commended for devising "appropriate technology" to solve a complicated aspect of the task; I suppose that we were simply used to improvising on tight budgets.

In March of 1994 the Robert J. Collier Trophy for 1993 was awarded to the Hubble Space Telescope Repair Team. The Collier Trophy was established in 1911 and is regarded as the highest award in US aviation. It is presented annually by the National Aeronautic Association "for the greatest achievement in aeronautics or astronautics in America, for improving the performance, efficiency, or safety of air or space vehicles, the value of which has been thoroughly demonstrated by its actual use during the preceding year." The citation accompanying the award read "For outstanding leadership, intrepidity, and the renewal of public faith in America's space program by the successful orbital recovery and repair of the Hubble Space Telescope." While the seven astronaut crew members and four ground managers of STS-61 were named as the recipients of the award, they represented more than 1,200 people who had a direct involvement in this mission. History should not forget this may have been the mission that saved NASA too.

In March of 1994 the Robert J. Collier Trophy for 1993 was awarded to the Hubble Space Telescope Repair Team. The Collier Trophy was established in 1911 and is regarded as the highest award in US aviation. It is presented annually by the National Aeronautic Association "for the greatest achievement in aeronautics or astronautics in America, for improving the performance, efficiency, or safety of air or space vehicles, the value of which has been thoroughly demonstrated by its actual use during the preceding year." The citation accompanying the award read "For outstanding leadership, intrepidity, and the renewal of public faith in America's space program by the successful orbital recovery and repair of the Hubble Space Telescope." While the seven astronaut crew members and four ground managers of STS-61 were named as the recipients of the award, they represented more than 1,200 people who had a direct involvement in this mission. History should not forget this may have been the mission that saved NASA too.

Right: Collier Trophy residing at the National Air & Space Museum (33,338 bytes).

Click on image to see enlarged view (137,469 bytes).

It was a privilege to work with this team, and to have made some small impact on history. I experienced and participated firsthand in the ingenuity of this team, the struggles that go on between management and engineers about matters such as time taken to double check when measured against the risk of a costly delay, and more. Having worked in the Federal service and again seeing the professionalism and intellect of civil servants at their best, I am reminded that America's worship and payment of celebrity (movie stars, professional athletes, etc.) is indeed shallow. The real American heroes when paid in dollars are often paid far less than their true worth.

Martin Cohen

Company Seven

Mission Astronauts: Commander Richard O. Covey, Pilot Kenneth D. Bowersox, Payload Commander F. Story Musgrave

Mission Specialists Kathryn C. Thornton, Claude Nicollier, Jeffrey A. Hoffman and Thomas D. Akers.

![]() NASA STS-61 Mission Press Kit. The complete 53 page color illustrated document prepared by NASA for distribution to the media and educators with information about: who were involved (as public contacts), explanations of general information, cargo bay payload and planned activities, in cabin payloads, crew biographies, acronyms and abbreviations, planned space walks, Shuttle abort plans, STS-61 vehicle and payload weights, timeline, history and plans for the HST, HST repair procedure (695,851 bytes).

NASA STS-61 Mission Press Kit. The complete 53 page color illustrated document prepared by NASA for distribution to the media and educators with information about: who were involved (as public contacts), explanations of general information, cargo bay payload and planned activities, in cabin payloads, crew biographies, acronyms and abbreviations, planned space walks, Shuttle abort plans, STS-61 vehicle and payload weights, timeline, history and plans for the HST, HST repair procedure (695,851 bytes).

NASA STS-61 Mission Press Kit. A text version of the Press Kit with information about: who were involved (as public contacts), explanations of general information, cargo bay payload and planned activities, in cabin payloads, crew biographies, acronyms and abbreviations, planned space walks, Shuttle abort plans, STS-61 vehicle and payload weights, timeline, history and plans for the HST, HST repair procedure (82,693 bytes).

![]() NASA STS-61 Launch. A 4 minute long NASA video showing the launch of the Shuttle Endeavor on the evening of 2 December 1993 from NASA Kennedy Space Flight Center. Coverage includes final countdown, engines and SRB ignition, lift off, roll maneuver, and SRB separation. This is in Audio Video Interleave (.avi) video and audio format and will play on most enabled browsers and video players.

NASA STS-61 Launch. A 4 minute long NASA video showing the launch of the Shuttle Endeavor on the evening of 2 December 1993 from NASA Kennedy Space Flight Center. Coverage includes final countdown, engines and SRB ignition, lift off, roll maneuver, and SRB separation. This is in Audio Video Interleave (.avi) video and audio format and will play on most enabled browsers and video players.

- After selecting the link a separate window will open, allow some time to download and start playing the file. Pop-up Windows must be enabled!

![]() NASA STS-61 Mission Video. A 24 minute long NASA video file narrated by the astronauts who flew on STS-61. This shows the launch of the Shuttle Endeavor, video of life aboard the Shuttle, preparation for space walks and the work being performed, views of the Earth (astronauts point out several cities on Earth as seen an night by their skyglow, most notably Las Vegas), views of natural phenomena (Aurorae, lighting) seen from space, and the landing at NASA Kennedy Space Flight Center on 13 December. This is a 52.8 megabyte file in Audio Video Interleave (.avi) video and audio format and will play on most enabled browsers and video players.

NASA STS-61 Mission Video. A 24 minute long NASA video file narrated by the astronauts who flew on STS-61. This shows the launch of the Shuttle Endeavor, video of life aboard the Shuttle, preparation for space walks and the work being performed, views of the Earth (astronauts point out several cities on Earth as seen an night by their skyglow, most notably Las Vegas), views of natural phenomena (Aurorae, lighting) seen from space, and the landing at NASA Kennedy Space Flight Center on 13 December. This is a 52.8 megabyte file in Audio Video Interleave (.avi) video and audio format and will play on most enabled browsers and video players.

- After selecting the link a separate window will open, allow some time to download and start playing the file. Pop-up Windows must be enabled!

Contents Copyright 1994-2009 all rights reserved by Company Seven and respective contributors, all space images and film courtesy of NASA.